Coal Mining Cylinder Bottom

1.Material:27SiMn

2.Machining accuracy:

Excircle: ±0.01mm

3.Mold opening cycle:About 45days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight/Size:Material usage and end-product weight will be derived from the Client’s provided drawings.

Product Introduction:

The cylinder backside is an vital phase of hydraulic actuators (such as hydraulic cylinders and jacks) in coal mine machinery. Located at the stop of the cylinder barrel, it undertakes the key features of sealing hydraulic oil, bearing hydraulic thrust and defending inner components, and is a "terminal barrier" to make certain the steady operation of the hydraulic system. Under the complicated working prerequisites of coal mines, the overall performance of the cylinder backside immediately influences the effectivity and protection of core operations such as lifting, pushing, and aiding of the equipment.

Product Advantages:

The cylinder backside is normally cast from brilliant steel. Through forging processing, the inner shape of the steel will become denser and extra uniform, and the grains are refined, thereby enhancing the strength, durability and fatigue resistance of the cylinder bottom. It can work stably underneath long-term high-pressure and heavy-load conditions, and is now not susceptible to troubles such as deformation and cracking, making sure the reliability and protection of coal mine machinery. The cylinder backside can carefully cooperate with different sealing factors to efficaciously stop the leakage of hydraulic oil, make certain the stress balance of the hydraulic system, and enhance the work effectivity and strength utilization price of coal mine machinery.

Production Process:

Raw material inspection→Cutting→Forging→Normalizing→Rough turning→UT→Quenched and tempered→Shot peening→MT→Finished turning→Drilling and Tapping→CMM/GMM→Cleaning packaging

Packaging And Shipping:

For each and every and every and each and each and every order, our professional crew ensures strict pinnacle notch control:

1.Pre-shipment preparation: Products are cleaned, labeled with batch numbers, and lined with rust-resistant materials.

2.Quality assurance: A one-of-a-kind considered take a exhibit up at is carried out to verify floor finish, labeling accuracy, and anti-corrosion integrity.

3.Logistics readiness: Items are professionally packed (e.g., in trees crates or bubble wrap) and saved in our warehouse for rapid turnaround.

4.Rest assured, your order will meet the very first-rate necessities and be geared up for except lengthen delivery.

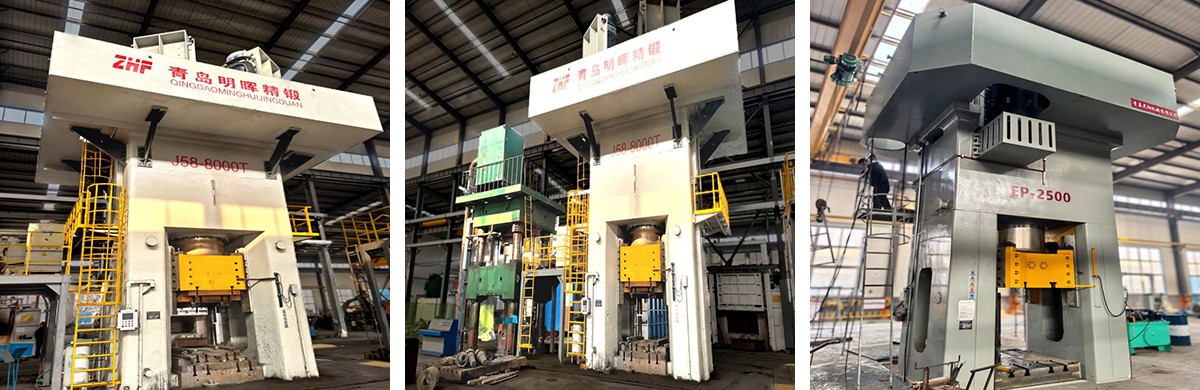

Company Strength:

The organization is geared up with best inspection and checking out gadgets such as imported spectrometers, nitrogen-hydrogen-oxygen analyzers, Zeiss metallographic microscopes, Zeiss CMMs, and M2M ultrasonic phased array flaw detectors. It has the entire simple usual overall performance to behavior inspections from uncooked fabric composition, performance, dimensions, structure and characteristic tolerances to non-destructive testing.