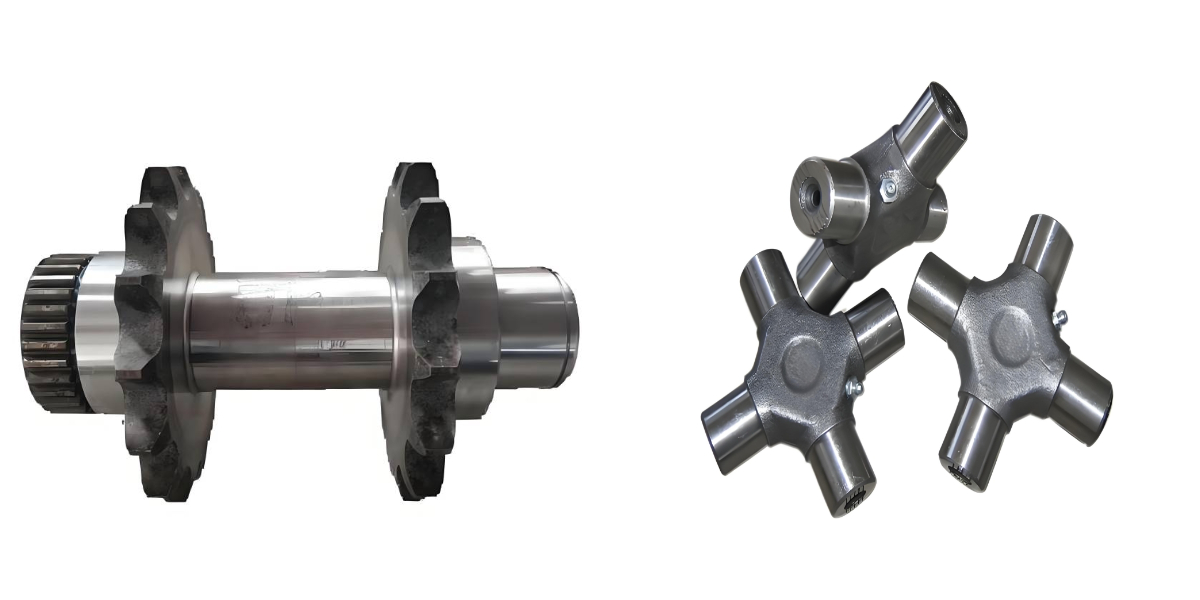

Petrochemical equipment forgings: Chain wheel + Cross shaft dual core, the guardian of heavy-load and corrosion scenarios!

Petrochemical equipment forgings: Chain wheel + Cross shaft dual core, the guardian of heavy-load and corrosion scenarios!

In the petrochemical production process, equipment needs to endure extreme conditions such as high temperature, high pressure, strong corrosion, and heavy-load impact for an extended period. The stable operation of the transmission system directly determines the continuity and safety of production. The chain wheel, as the core component for material transportation and equipment drive, and the cross shaft, as the key hub for universal transmission, both rely on the high strength, high toughness, and corrosion resistance of forgings to become indispensable "core components" of petrochemical installations. Many purchasing managers and operation teams of chemical enterprises often wonder: Why must petrochemical chain wheels and cross shafts be selected as forgings? How can high-quality forgings enable these two components to withstand harsh conditions? How should different petrochemical scenarios be selected? This article dissects the key roles of petrochemical equipment chain wheel and cross shaft forgings from three dimensions: core value, process advantages, and selection guidelines.

I. Forging empowerment: Chain wheel and cross shaft, the "golden combination" of petrochemical transmission

In the transmission chain of petrochemical production, the chain wheel is responsible for driving key equipment such as conveyor belts and mixers, while the cross shaft is responsible for power transmission and angle compensation in different shaft systems. Both need to simultaneously withstand heavy loads, corrosion, and high temperatures. Forging is the core guarantee for achieving long-term stable operation:

1. Petrochemical chain wheel forgings: The "power gear" for material transportation and equipment drive

In petrochemical scenarios, chain wheels are widely used in scraper conveyors, bucket elevators, and chain conveyors, etc. They need to continuously withstand material scouring, heavy-load traction, and chemical medium erosion. The quality of their forgings directly affects the conveying efficiency and equipment lifespan:

Using 20CrMnTi, 42CrMo, etc. high-strength alloy steel for die forging, through 1100-1200℃ high-temperature forging + multiple passes of fine forging, the metal grain is fine and uniform, with a density of 99.9%, completely eliminating pores, sand holes, etc., with tensile strength of over 1000 MPa and yield strength of ≥ 800 MPa, capable of easily withstanding the traction load of tens of thousands of tons of material transportation;

The tooth surface undergoes carburizing + quenching treatment, with hardness of HRC58-62, the wear resistance is more than three times that of ordinary castings, with a tooth surface wear rate controlled within 0.05mm/1000 hours, a lifespan of up to 8-10 years, which is 2 times longer than castings, reducing downtime losses caused by frequent replacements;

For petrochemical corrosive environments, the surface is treated with galvanization + passivation, spraying of anti-corrosion coatings, etc., with salt spray corrosion resistance of over 1500 hours, excellent acid and alkali corrosion resistance (pH value 2-12), suitable for crude oil extraction, refining, chemical raw material transportation, etc. scenarios.

2. Petrochemical cross shaft forgings: The "flexible hub" of universal transmission

The cross shaft is the core component of universal couplings in petrochemical pumps, compressors, fans, etc., and needs to achieve precise power transmission at different angles, while buffering vibration and coaxiality deviations during operation. The performance of the forging determines the stability of the shaft system transmission:

Using 35CrMo, 40CrNiMoA alloy steel for integrated die forging, avoiding structural weaknesses caused by welding, with tensile strength of over 1100 MPa, torsional fatigue life of 10⁷ cycles, capable of withstanding high-speed torque impact under high temperatures (≤450℃), high pressures (≤30MPa);

The shaft neck surface undergoes quenching + grinding treatment, with roughness Ra≤0.8μm, size tolerance controlled within ±0.03mm, combined with high-precision needle roller bearings, transmission efficiency is over 99%, reducing power loss, suitable for the high-frequency operation requirements of petrochemical equipment; Optimize the structure for different working conditions: The cross shaft forgings of the refining and chemical plants adopt a hollow structure, reducing weight by 15% while improving heat dissipation performance; The cross shaft forgings of the offshore oil platforms are made of stainless steel resistant to seawater corrosion, combined with cathodic protection technology, extending the anti-corrosion life by 3 times.

3. Synergy: Forge a "fault-free transmission loop"

The performance matching of the chain wheel and the cross shaft forgings forms the "transmission safety loop" of the petrochemical equipment: The buffering and vibration-damping effect of the cross shaft can reduce the impact on the chain wheel during power transmission, and reduce the risk of tooth surface wear and fracture; While the high strength and wear resistance of the chain wheel can stably receive the power transmitted by the cross shaft, ensuring continuous and uninterrupted material transportation and equipment driving, reducing the failure rate of the petrochemical device transmission system to below 0.1%, and building a defense line for continuous production.

II. Forging Process: The "Build-Resistant Code" of Chain Wheel and Cross Shaft Forgings

The strictness of the petrochemical working conditions determines that the chain wheel and cross shaft must adopt forging technology instead of casting or stamping. The core advantages are reflected in three points:

Strength and toughness dual excellence, resisting extreme loads: The forging process makes the metal fiber flow lines continuously distributed along the force direction of the component, compared with the castings, the tensile strength is increased by 40%-60%, the impact toughness (αk) reaches above 90J/cm², which can effectively avoid fracture and deformation under high temperature and high pressure - this is crucial for the stress concentration parts such as the tooth root of the chain wheel and the shaft neck of the cross shaft;

Wear resistance and corrosion resistance, extending service life: High-quality alloy steel materials combined with composite processes such as carburizing, nitriding, and anti-corrosion coatings, the wear resistance and corrosion resistance of the forgings far exceed those of the castings, and can operate in harsh environments such as crude oil, acid-base media, and high-temperature steam, reducing maintenance frequency and costs;

Dimensional accuracy, strong adaptability: Precision die forging technology realizes "near-net shape formation", the tooth shape accuracy of the chain wheel reaches the GB/T 1244-2016 8th standard, the roundness error of the cross shaft shaft neck is ≤ 0.01mm, no need for a large amount of subsequent processing can be directly assembled, avoiding vibration, noise and increased wear caused by the mismatched clearance.

III. Selection Guide: 3 Key Points for Selecting Petrochemical Chain Wheels and Cross Shaft Forgings

For petrochemical enterprise purchasers and operation teams, to select the right chain wheel and cross shaft forgings, it is necessary to precisely match according to specific working conditions, and focus on three points:

Verify process and testing qualifications: Preferentially choose suppliers that adopt die forging + electro-hydraulic hammer forging, and require them to provide complete test reports - material analysis reports, ultrasonic testing (UT), magnetic particle testing (MT), and penetrant testing (PT), ensuring that there are no cracks, inclusions, or porosity defects in the internal of the forgings, with a qualification rate of 99.8% or above; At the same time, confirm that the products comply with industry standards such as GB/T 3077 (alloy structural steel standard), HG/T 20644 (chemical equipment forging standard), or API (American Petroleum Institute standard).

Match working conditions with material and structure:

High-temperature scenarios (such as catalytic cracking plants): The chain wheel and cross shaft forgings are all selected from heat-resistant alloy steel (such as 30Cr2Ni2Mo), with a temperature resistance of over 500℃, avoiding high-temperature creep;

Corrosion scenarios (such as seawater desalination, acid-base chemical processes): Select stainless steel (316L, 2205 duplex steel) or Hastelloy alloy forgings, combined with anti-corrosion coatings, enhancing anti-corrosion ability;

Heavy-load scenarios (such as large scraper conveyors): Select 42CrMo, 40CrNiMoA high-strength alloy steel forgings, strengthening the hardness of the tooth surface and the strength of the shaft neck, improving impact resistance. Focus on the manufacturer's production capacity and cases: Prioritize choosing suppliers with a complete industrial chain (smelting - forging - heat treatment - finishing), ensuring material consistency and process stability; pay close attention to whether the manufacturer has cooperation cases with large petrochemical enterprises such as Sinopec, CNOOC, and CNOOC, and whether the products have been verified in actual working conditions for more than 5 years; at the same time, confirm their customization capabilities, which can adjust the forging structure and process according to equipment models and working condition parameters, and meet the requirements of non-standard equipment needs.

IV. Industry Trends: The upgrading of the petrochemical industry drives the evolution of forgings to "high precision, high technology"

As the petrochemical industry transforms towards "large-scale, intelligent, and green", the market size of petrochemical forgings is expected to exceed 50 billion yuan in China by 2025. The demand for core transmission forgings such as chain wheels and cross shafts continues to grow. The industry presents three major upgrading trends:

Precision: Through digital twin technology to simulate the forging process, optimize the tooth shape of chain wheels and the structure of cross shafts, and the dimensional accuracy reaches micrometer level, improving the transmission efficiency by 3%-5%;

Corrosion resistance: Developing new corrosion-resistant alloy materials (such as nickel-based alloys, titanium alloys), combined with advanced anti-corrosion processes, extending the service life of forgings in extreme corrosive environments by more than 50%;

Intelligence: Implanting micro sensors inside the forgings to achieve real-time monitoring of temperature, stress, wear, etc., early warning of fault risks, reducing operation and maintenance costs, and meeting the requirements of intelligent management of petrochemical equipment.

Currently, domestic petrochemical chain wheels and cross shaft forgings have achieved 90% or more import substitution, and some high-end products have reached international advanced levels, becoming the preferred choice for petrochemical enterprises to reduce costs and increase efficiency.

Summary

Forgings for petrochemical equipment chain wheels and cross shafts are the "two cores" of the transmission system - the former drives the efficient operation of equipment and stable material transportation, the latter ensures precise power transmission and the safety and stability of the shaft system. The high-quality forging characteristics of these two types directly determine the continuity, safety, and economy of petrochemical production. In the increasingly demanding petrochemical industry, choosing high-quality forgings that are suitable for the scenarios has become the key to enhancing the core competitiveness of enterprises.

If you need to further understand the customized solutions for petrochemical chain wheels and cross shaft forgings, the adaptation cases for different working conditions, or obtain the technical parameter comparison table, corrosion material selection guide, please feel free to contact us! We will provide you with high-quality forging products and professional technical support that comply with industry standards.