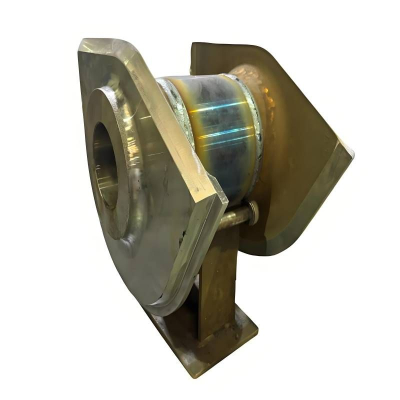

Forged And Welded Shaft Bracket Assembly

1.Material:35#(ASTM:1035 EN:C35E4 DIN:CK35),20MnMo,20#

2.Machining accuracy:±0.5mm

3.Customization: We design and manufacture tailor-made products to your exact technical requirements.

4.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

5.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

6.Craft:Forging

7.Size:Execute custom orders with complete compliance to the drawings provided.

Product Introduction:

The front support seat (also termed the front axle seat, front mounting seat, or rear pivot) is the core load-bearing component connecting the excavator frame and boom. It plays a critical role in transmitting operational loads, ensuring structural stability, and enabling flexible movement. With the future adoption of self-sensing lubrication systems and predictive maintenance technologies, the front support seat will evolve into an integrated system characterized by "self-adaptation → self-repair → extended service life", thereby becoming a core competitive feature of high-end excavators .

Product Advantages:

The enlarge and stick shaft seat assembly of an excavator is a core load-bearing aspect in the working machine of an excavator. Its product advantages are usually mirrored in material innovation, structural design, manufacturing manner and realistic optimization. The core advantages of the excavator boom and stick shaft seat assembly lie in: material upgrade, forged and quenched factors + wear-resistant coating, doubling the provider life; structural innovation, adjustable measurement structure + modular interior sleeve, enhancing every adaptability and economy; manufacturing precision, robotic welding + positioning fixtures, making certain millimeter-level assembly accuracy; safety convenience, surfacing fix and modular replacement, substantially lowering operation and renovation costs. Through the integration of resources science, structural mechanics and clever manufacturing technology, this assembly has finished a whole average overall performance bounce forward in immoderate strength, prolonged provider existence and low maintenance, turning into a key information for bettering the reliability of present day excavator working devices.

Production Process:

Forgings + Pipe Fittings Assembly → Welding → Non-Destructive Testing → Cleaning & Packaging → Shipment

Our team will:

Clean, label, and take a showcase up at rust-proofing to all merchandise in the previous than shipment;

Perform a meticulous exhibit off up inspection

Finally pack the merchandise and keep them in our warehouse, making notably authentic readiness for dispatch.

Company Strength:

Over the previous 30 years of energetic development, the business enterprise has aggressively prolonged into each and every and every and each and every home and world markets. Its merchandise are notably used in fields such as inserting up machinery, wind electrical electrical electricity generation, new electrical energy vehicles, rail transit, petrochemicals, and mining machinery. The organisation corporation has set up in-depth cooperation with world-renowned corporations in the United States, Canada, Germany, Italy, Belgium, Japan, and gorgeous countries, with some distance away areas capital customer profits accounting for huge than 50%. It has in addition normal strategic partnerships with home predominant high-end tools producers such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. Among its products, the market share of planetary reducer core forgings and medium-to-large lifting hook assemblies ranks first in the home market.