Excavator Long Boom Assembly

1.Material:35#(ASTM:1035 EN:C35E4 DIN:CK35),20MnMo,20#

2.Machining accuracy:±0.5mm

3.Customization: We design and manufacture tailor-made products to your exact technical requirements.

4.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

5.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

6.Craft:Forging

7.Size:Execute custom orders with complete compliance to the drawings provided.

Product Introduction:

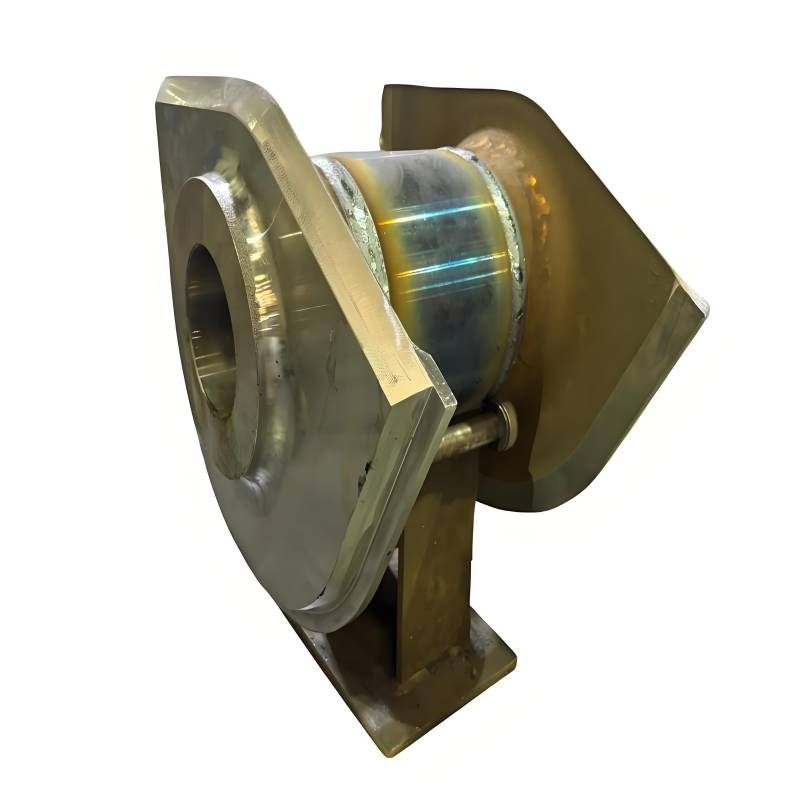

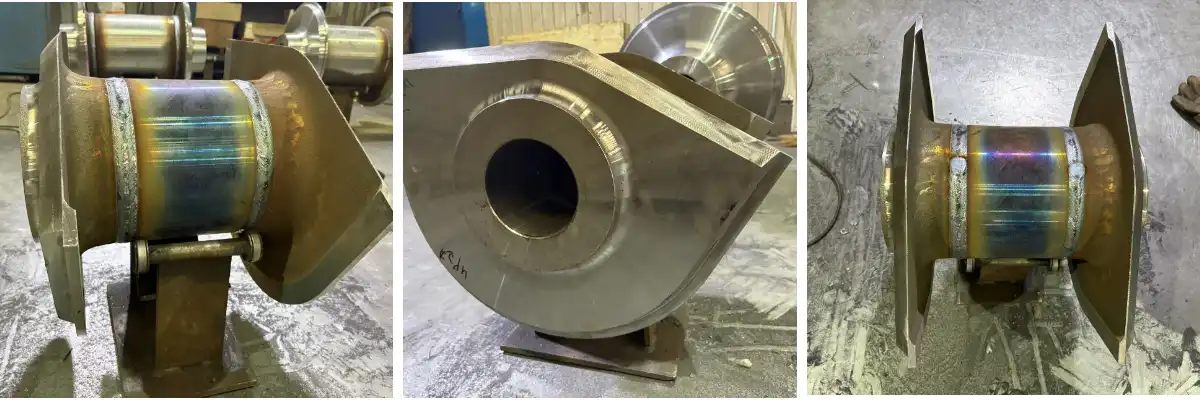

The support welded assembly (alternatively referred to as the axle welded assembly, front support base welded assembly, or rear bracket welded assembly) serves as a critical load-bearing component in excavator booms, forming the connection between the boom and the arm. Its key functions include transferring operational loads, maintaining stable equilibrium during work, and facilitating the flexible articulation needed for excavation tasks. Looking ahead, as self-sensing lubrication structures and predictive maintenance technologies become more prevalent, this assembly is poised to evolve toward an integrated system characterized by "self-adaptation, self-monitoring, and extended service life." This advanced design will not only enhance its durability and operational efficiency but also emerge as a defining competitive feature of premium, high-performance excavators in the market.

Product Advantages:

The support welded assembly stands as a pivotal load-bearing component within an excavator’s working mechanism. Its competitive strengths span four core dimensions: material innovation, structural design, manufacturing precision, and intelligent optimization.

Key advantages of this excavator boom’s support shaft seat assembly include:

Upgraded materials: Forged, quenched components paired with wear-resistant coatings, effectively doubling the part’s service life.

Structural innovation: An adjustable-profile frame combined with modular inner sleeves, boosting both adaptability to diverse working conditions and cost-efficiency in production.

Precision manufacturing: Automated robotic welding paired with precision positioning jigs, ensuring assembly accuracy down to the millimeter level.

Ease of maintenance & safety: Surfacing repair compatibility and modular replacement design, drastically cutting operational and upkeep costs.

By integrating material science, structural mechanics, and smart manufacturing technologies, this assembly delivers comprehensive performance leaps in terms of high load-bearing capacity, extended durability, and low maintenance demands—ultimately serving as a critical driver for enhancing the reliability of modern excavator working systems.

Forgings + Pipe Fittings Assembly → Welding → Non-Destructive Testing → Cleaning & Packaging → Shipment

Packaging and Shipping

Our team is committed to upholding the strictest quality standards for every product prior to customer delivery, and we’ve established a rigorous, end-to-end process to achieve this:

To start, every item undergoes a deep cleaning protocol to eliminate manufacturing dust, residual debris, or storage-related contaminants. Each product is then clearly labeled with essential details—including model number, batch code, and handling guidelines—ensuring full traceability and clarity across the entire supply chain. Next, we apply tailored, industry-grade rust-proofing treatments: for metal components, this may involve protective coatings or specialized films matched to the material, safeguarding against corrosion during transit and storage. This is followed by a meticulous quality inspection: our specialists verify structural integrity, functional performance, surface finish, and adherence to all specifications, identifying and resolving any defects immediately—only products meeting perfect condition move forward. Finally, qualified items are packaged in durable, custom-fitted materials to prevent transit damage, then stored in our climate-controlled warehouse (where inventory is closely managed to preserve optimal conditions). This keeps all products fully prepared for prompt, efficient dispatch once orders are confirmed. Through this stringent workflow, we guarantee every product reaches customers in immaculate, ready-to-use condition.

Company Strength:

Over three decades of steady expansion, the company has secured its status as an industry leader by strategically scaling across both domestic and global markets. Its product lineup delivers versatile solutions across critical sectors—including construction machinery, wind power, new energy vehicles, rail transit, petrochemicals, and mining equipment—proven to adapt to diverse industrial demands. A cornerstone of its strength is its global reach: the firm has forged long-standing partnerships with top international enterprises in the U.S., Canada, Germany, Italy, Belgium, Japan, and more. This global footprint is underscored by overseas sales contributing over 50% of total revenue, highlighting its robust competitiveness on the world stage. Domestically, it maintains strategic alliances with industry giants like Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear, solidifying its position as a trusted supplier to leading local manufacturers. The company also leads key product segments: its planetary reducer core forgings and medium-to-large hook assemblies hold the top domestic market share, a reflection of its technological expertise, premium quality, and ability to meet the rigorous requirements of high-end industrial applications. By combining global market penetration, partnerships with industry leaders, and dominance in core product categories, the company stands as a reliable, innovative force—well-positioned to drive continued growth in the sector.