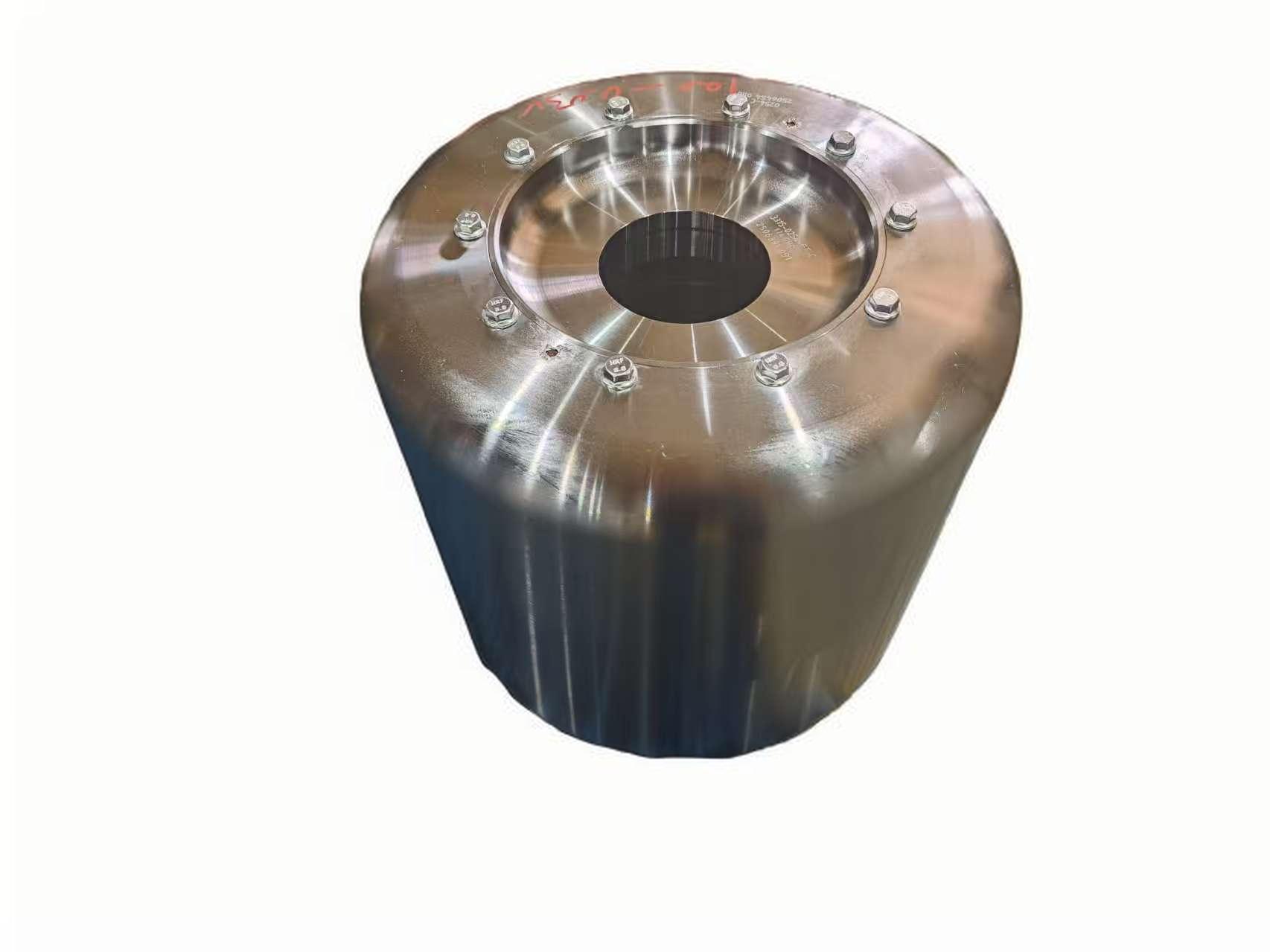

Forging Electric Car Hub

1.Material:42CrMo

2.Machining accuracy:±0.01mm

3.Mold opening cycle:About 45 days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

7.Craft:Forging

Product Introduction:

Forged hubs boast a dense, pore-free molecular structure—eliminating the casting defects common in traditional alternatives—while achieving exceptional lightweighting. This significant reduction in unsprung mass directly boosts the range and handling performance of new energy vehicles (NEVs). Engineered to align with the core demands of electrification, forged hubs excel in thermal dissipation, effectively managing the heat generated by high-efficiency electric drivetrains. Additionally, their robust structural integrity delivers superior impact resistance, enabling them to withstand the extreme torque outputs characteristic of NEV powertrains.

Product Advantages:

Hubs for new energy vehicles (NEVs), renowned for their exceptional strength, lightweight properties, high reliability, and customizable adaptability, have evolved into a core component of powertrain and chassis systems. Crafted through forging technology, these hubs are free from casting defects such as pores and shrinkage porosity, boasting superior impact resistance. They can withstand the impact of road bumps and potholes, significantly reducing the risks of tire blowouts and hub fractures. Adopting near-net-shape forming technology, the hub forging process minimizes material waste from cutting operations, perfectly aligning with the "low-carbon and environmental protection" concept inherent to the new energy industry. By virtue of material upgrades, process innovations, and structural optimization, NEV hub forgings have overcome the performance bottlenecks of traditional cast hubs in terms of strength, weight, and heat dissipation. Today, they stand as key enablers driving the development of new energy vehicles toward "high performance, extended range, and intelligentization."

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → CMM/GMM → Cleaning packaging

Packaging and shipping:

Our seasoned team of quality assurance specialists executes a rigorous, end-to-end quality control protocol for every single order, upholding uncompromising standards to deliver excellence. Prior to shipment, each product undergoes a comprehensive pre-dispatch preparation: it is thoroughly cleaned using industrial-grade processes to eliminate manufacturing residues, dust, and contaminants, ensuring a pristine condition. Every item is then clearly and accurately labeled with critical information—including product model, batch number, material specifications, and handling guidelines—to enable full traceability across the supply chain. Following this, we apply a professional, material-specific anti-corrosion treatment, such as high-performance rust-proof coatings or vapor corrosion inhibitors (VCIs), to safeguard metal components (especially forged parts like NEV hubs or excavator seat rings) against oxidation and deterioration during transit and storage. Subsequently, a meticulous multi-dimensional inspection is conducted by our certified QC experts. This exhaustive check covers structural integrity, dimensional accuracy, surface finish, functional performance, and strict compliance with international standards (e.g., ISO) and customer-specific technical requirements. Any discrepancies are promptly addressed and resolved, ensuring only products that meet our top-tier quality benchmarks proceed to packaging. Finally, the qualified products are carefully packed using durable, custom-fitted packaging materials—equipped with shock-absorbing and moisture-proof features—to prevent scratches, impacts, or damage during transportation. These items are then systematically stored in our well-organized, climate-controlled warehouse, where inventory is managed via an advanced logistics system to maintain optimal condition. This ensures all products are fully prepared for immediate, efficient dispatch the moment orders are confirmed, minimizing lead times and ensuring timely delivery to global clients.

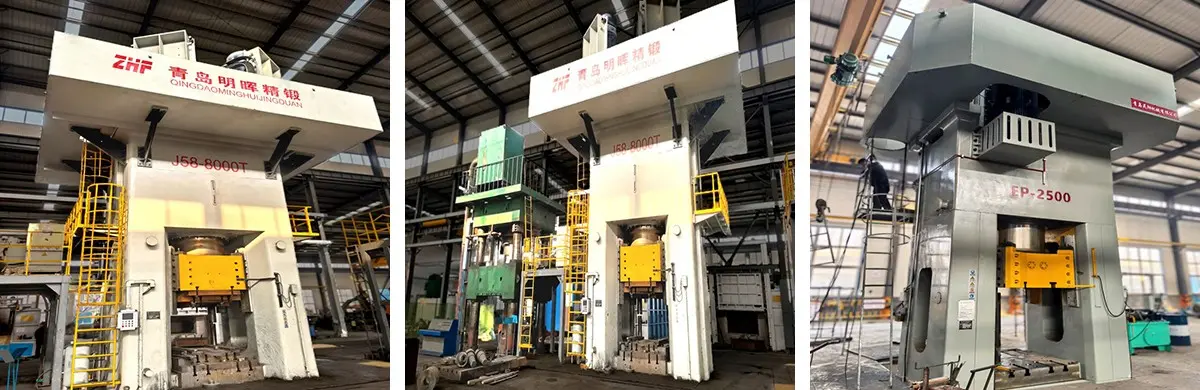

Company Strength:

The company’s quality management system is continuously advancing toward digital transformation, integrating end-to-end online management across critical quality processes—including defect feedback, nonconformance review and disposition, full-lifecycle quality traceability, and stratified auditing. By leveraging digital tools and intelligent management platforms, the system streamlines data collection, analysis, and workflow execution: real-time defect reporting enables prompt issue escalation, standardized nonconformance review workflows ensure consistent decision-making, and granular quality traceability (covering raw materials, production steps, and final inspection) provides complete visibility into every product’s journey. Additionally, digital stratified auditing automates schedule tracking, documentation, and follow-up on corrective actions, eliminating manual inefficiencies. This digital overhaul has significantly elevated the standardization of quality processes, reduced administrative delays, and enhanced the timeliness of issue resolution—empowering the team to proactively identify root causes, implement targeted improvements, and maintain uncompromising quality standards across all operations.