Forging Lifting Hook Assembly

1.Material:45\35CrMo\40Cr\42CrMo\30Cr2Ni2Mo

2.Machining accuracy:±0.1mm

3.Mold opening cycle:About 45 days

4.Customization: Made-to-order services are available.

5.Advantages:

Full-process inspection

Full-process processing capability

Full-range products

6.Weight/Size: Produce according to the drawings.

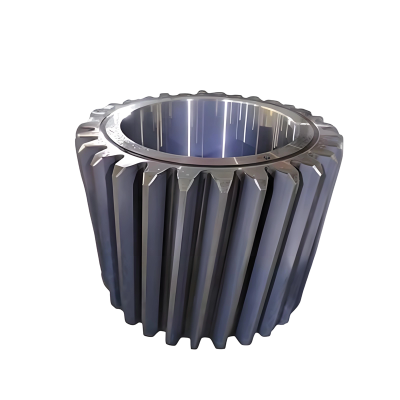

7.Craft:Forging

Product Introduction:

The hook assembly serves as a critical component in lifting equipment, primarily functioning to grasp and lift loads. Manufactured through forging processes, it boasts a dense internal structure, enhanced mechanical strength and toughness, and most notably, excellent impact resistance. These properties allow it to withstand heavy weights and frequent usage. Typically, it finds wide application across the industrial sector, construction industry, logistics and warehousing field, as well as the transportation sector.

Product Advantages:

The hook assembly designed for crawler cranes delivers exceptional load-bearing capacity and impact resistance, enabling it to adapt to harsh working environments. It is particularly well-suited for heavy-duty hoisting tasks and operations on difficult terrains. By utilizing high-strength materials, heavy-duty structural designs, and multiple safety protection mechanisms, this hook assembly excels in long-term heavy-load operations while offering a flexible working range. In contrast, the hook assembly for truck cranes is distinguished by its lightweight construction, high mobility, operational flexibility, efficiency, and ease of maintenance. It is ideal for medium and small-scale hoisting projects, urban construction operations, large-scale relocation tasks, and multi-scenario applications. To achieve these advantages, it adopts lightweight materials, compact structural designs, and standardized components.

Production Process:

Raw material inspection → Cutting → Forging → Normalizing →Grinding→Rough turning →Quenched and tempered→ MT+UT→ Finished turning→ Milling groove →Drilling → CMM/GMM → Shot peening→Coating →Cleaning packaging

Packaging And Shipping:

Our dedicated team of quality experts implements a rigorous, multi-tiered QC protocol for every single order, leaving no detail to chance in upholding our uncompromising standards. Prior to shipment, each product undergoes a comprehensive preparation process: first, it is thoroughly cleaned using industrial-grade methods to eliminate all manufacturing residues, dust, and contaminants, ensuring a pristine finish. Every item is then clearly and accurately labeled with critical information—including product model, batch number, material specifications, and handling instructions—to enable full traceability across the entire supply chain. Following this, we apply a professional, material-specific anti-rust treatment, such as high-performance corrosion-resistant coatings or VCIs, to safeguard metal components (especially forged parts like seat rings and excavator forgings) against oxidation and degradation during transit and storage. Next, a meticulous, multi-dimensional quality inspection is conducted by our certified QC specialists. This exhaustive check covers structural integrity, dimensional accuracy (verified via precision measuring tools like CMMs), surface finish, functional performance, and strict compliance with international standards and customer-specific technical requirements. Any discrepancies or potential defects are immediately addressed and resolved, ensuring only products that meet our top-tier quality benchmarks proceed to packaging. Finally, the qualified products are carefully packed using durable, custom-fitted packaging materials—equipped with shock-absorbing and moisture-proof features—to prevent scratches, impacts, or damage during transportation. These products are then systematically stored in our well-organized, climate-controlled warehouse, where inventory is managed through an advanced logistics system to maintain optimal condition. This ensures all items are fully prepared for swift, efficient dispatch the moment orders are confirmed, minimizing lead times and ensuring timely delivery.

Company Strength:

The company prides itself on a world-class, cutting-edge inspection and testing infrastructure, anchored by industry-leading equipment including high-precision imported spectrometers for ultra-accurate chemical composition analysis, advanced nitrogen-hydrogen-oxygen analyzers that ensure exceptional material purity by detecting trace impurities at ppm-level sensitivity, state-of-the-art Zeiss metallographic microscopes for in-depth metallurgical structure evaluation (critical for validating forging quality), Zeiss coordinate measuring machines (CMMs) with micron-level precision to verify complex dimensional and geometric tolerances, and top-tier M2M ultrasonic phased array flaw detectors for non-destructive testing (NDT) with unparalleled defect localization and sizing capabilities. This comprehensive, best-in-class equipment suite empowers the company with unrivaled end-to-end quality assurance capabilities, covering every critical stage of product validation—from rigorous raw material screening (including chemical composition verification, mechanical property testing, and purity analysis for forging-grade alloys) to meticulous inspections of semi-finished and finished components. It enables precise validation of dimensional accuracy, geometric tolerances, structural integrity, surface finish, and functional performance, while the advanced NDT solutions deliver thorough, non-invasive detection of internal flaws such as cracks, inclusions, or porosity in high-load, mission-critical parts like excavator forgings, seat rings, and gear shafts. By leveraging these industry-leading testing technologies, the company not only adheres to the most stringent international quality standards (including ISO, ASTM, and industry-specific certifications) but also demonstrates an unwavering commitment to delivering ultra-reliable, high-performance products for demanding sectors such as construction machinery, wind power, rail transit, and heavy industrial equipment. This robust quality control ecosystem not only minimizes production risks and ensures consistent product excellence but also solidifies the company’s reputation as a trusted, technologically advanced partner—capable of meeting the most rigorous quality requirements of global clients and distinguishing itself in the competitive forging and precision component market.