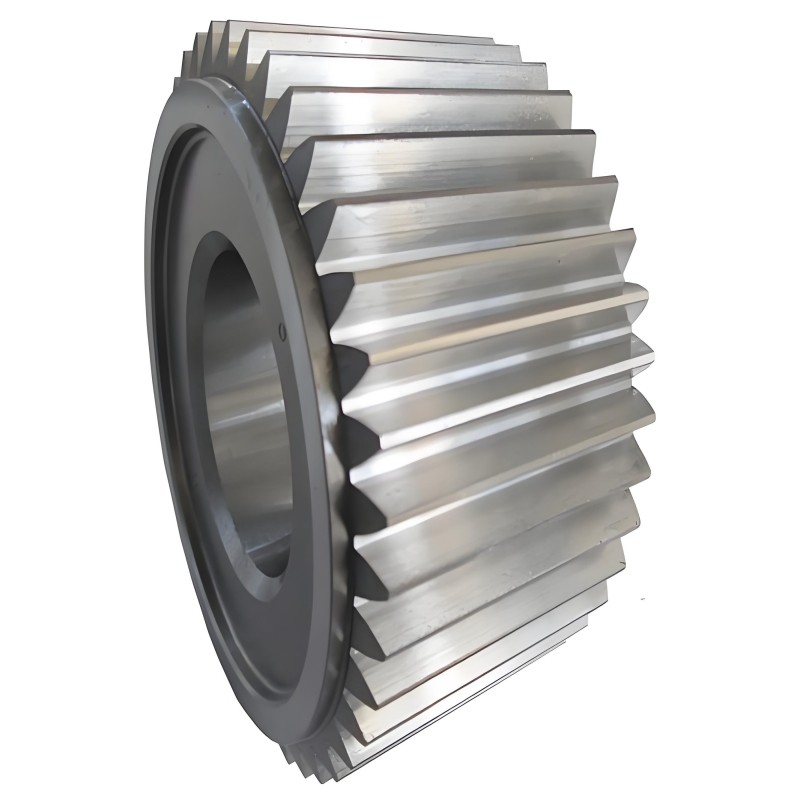

Forging Planetary Gear

1.Material:17CrNiMo6-4/18CrNiMo7-6

2.Machining accuracy:

External cylindrical grinding: ±0.001mm

Tooth accuracy: Grade 5

3.Mold opening cycle:About 30 days

4.Customization: Made-to-order services are available.

5.Advantages:

Full-process inspection

Full-process processing capability

Full-range products

6.Weight/Size: Produce according to the drawings.

7.Craft:Forging

Product Introduction:

Planetary gears are indispensable core components of the planetary gear train in wind turbine speed-increasing gearboxes, playing a vital role in enabling efficient power conversion from the turbine’s low rotor speed to the high speed needed for electricity generation. Their manufacturing workflow is notably complex and technically sophisticated, encompassing a sequential series of precision-focused steps: high-quality alloy steel production (to ensure consistent material properties), hot forging (to enhance structural integrity and mechanical strength), post-forging normalizing and tempering treatments (to relieve internal stresses and optimize material machinability), rough machining operations (such as turning and milling to shape the basic form), carburizing and quenching heat processes (to achieve a hard, wear-resistant surface and a tough core), and final precision finishing (including grinding and honing for ultra-fine dimensional control). Each stage of production mandates exceptionally strict requirements for processing accuracy and quality control. From material composition uniformity to machining tolerances and surface finish, every detail is meticulously regulated to ensure the planetary gears meet rigorous standards for dimensional precision, tooth profile accuracy, and surface smoothness. These stringent criteria are critical to guaranteeing the gears deliver stable, reliable performance under the extreme operating conditions of wind turbines—characterized by high rotational speeds, heavy dynamic loads, and continuous cyclic stresses—thus supporting the long-term efficiency and durability of the entire wind energy system.

Product Advantages:

As a core component of the planetary gear train, planetary gears exert a direct and decisive impact on the transmission efficiency, operational reliability, and service life of speed-increasing gearboxes—with their structural design ingenuity and manufacturing quality serving as key determinants of overall performance. Engineered with a multi-tooth load-sharing mechanism, they excel in space utilization, boasting a compact footprint that maximizes power density while striking an optimal balance between lightweight construction and robust mechanical strength. This design allows for seamless integration into constrained gearbox enclosures without compromising load-bearing capacity or durability. Equipped with advanced tooth profile modification technology—including optimized involute curve design and micro-topography adjustments—these gears deliver exceptional meshing precision. This refinement minimizes backlash, ensures uniform force distribution across tooth surfaces, and enables smooth, low-vibration, and low-noise power transmission even under dynamic operating conditions. Furthermore, the gear tooth surfaces undergo rigorous shot peening treatment: high-velocity metallic pellets are projected onto the surface to create a residual compressive stress layer, effectively counteracting tensile stresses generated during operation. This process significantly enhances the gears’ fatigue resistance, mitigates the risk of crack initiation and propagation, and ultimately extends their overall service life—critical for maintaining the long-term performance of speed-increasing gearboxes in demanding applications.

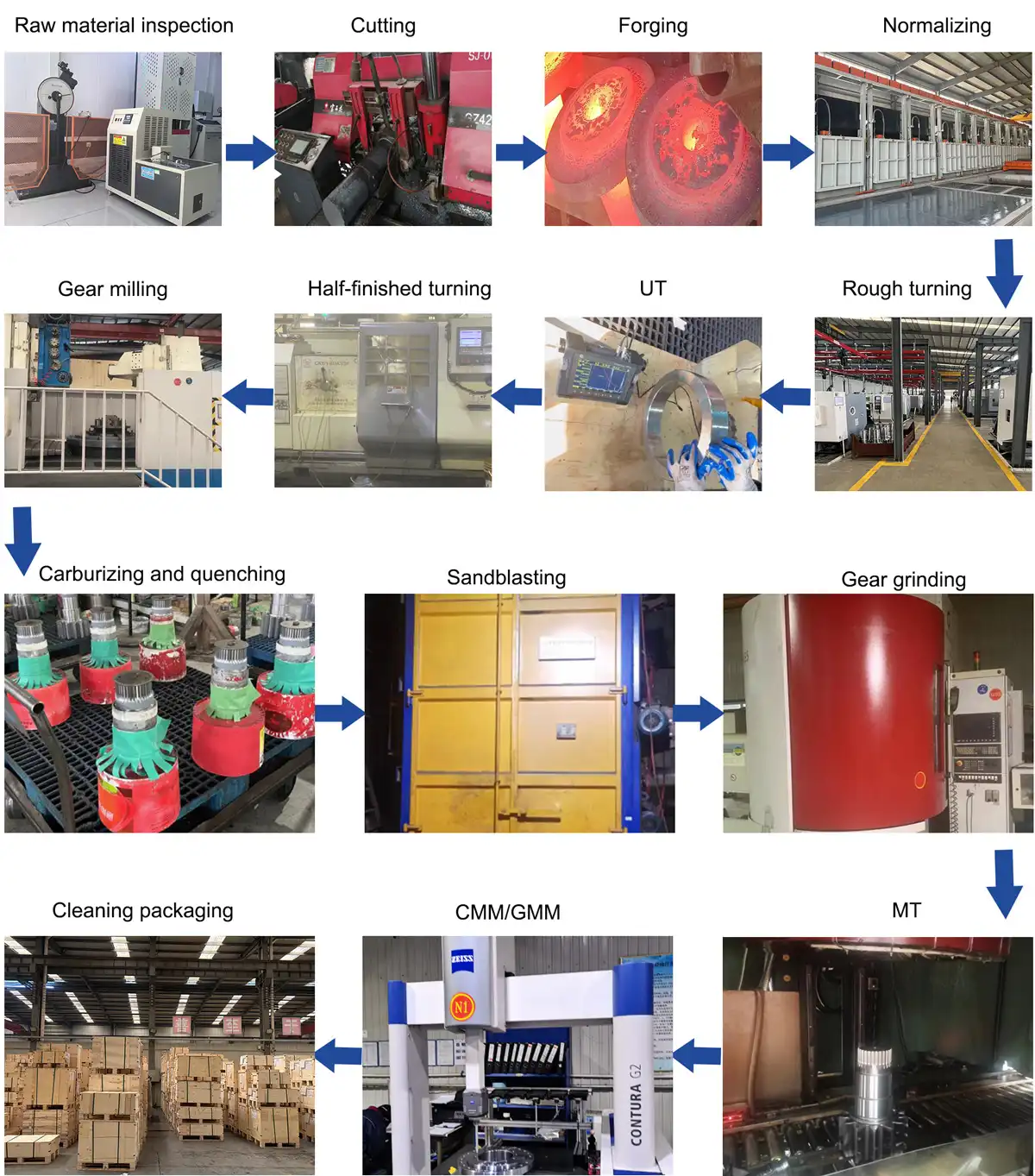

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Rough turning → UT → Half-finished turning → Gear milling → Carburizing and quenching → Sandblasting → Gear grinding → MT → CMM/GMM → Cleaning packaging

Packaging And Shipping:

Before products are dispatched, they must complete a comprehensive pre-shipment pre-treatment process that forms an interconnected quality control chain. First, each item undergoes thorough cleaning—utilizing ultrasonic or high-pressure cleaning methods—to eliminate surface contaminants, machining residues, and impurities, ensuring a pristine finish that meets aesthetic and functional standards. Next, standardized, regulatory-compliant labels are affixed, clearly displaying critical product details such as batch numbers, technical specifications, usage guidelines, and safety warnings for easy identification and proper application. Additionally, targeted anti-rust measures are implemented based on product materials: metal components receive corrosion-inhibiting coatings, vacuum-sealed packaging, or rust-preventive oils, while sensitive parts are wrapped in moisture-resistant films to slow oxidation and rust formation during storage and transit. Immediately following this, professional quality inspectors conduct a detailed visual examination, supplemented by basic dimensional checks, to identify any defects such as scratches, dents, deformities, or inconsistencies that may affect performance. Finally, products that pass inspection are properly packaged with protective materials—including shock-absorbing foam, reinforced cartons, and moisture-proof liners—to ensure safe transportation and prevent damage from handling or environmental factors. These qualified items are then temporarily stored in an organized warehouse, categorized by order for easy retrieval, and held pending shipment scheduling. This end-to-end process, from cleaning to warehousing, ensures products maintain optimal condition, laying a solid foundation for smooth transportation and reliable subsequent use by customers.

Company Strength:

The company is furnished with a full suite of cutting-edge, industry-leading inspection and testing equipment, featuring imported spectrometers, nitrogen-hydrogen-oxygen analyzers, Zeiss metallographic microscopes, Zeiss coordinate measuring machines (CMMs), and M2M ultrasonic phased array flaw detectors. This advanced hardware ecosystem endows the organization with comprehensive, end-to-end testing capabilities that span every critical quality dimension: it enables precise analysis of raw material chemical compositions, rigorous evaluation of material performance parameters (such as hardness and tensile strength), accurate measurement of dimensional precision and positional tolerances, and thorough assessment of structural integrity. Beyond these core functions, the equipment supports high-precision non-destructive testing (NDT)—a key capability that allows for the detection of minute internal defects, micro-cracks, or structural irregularities without compromising the integrity of materials or finished products. This robust, multi-layered testing framework ensures strict quality validation at every stage of production, from raw material incoming inspection to final product clearance. It not only guarantees the consistent reliability and superior quality of all outputs but also underscores the company’s unwavering commitment to upholding the most stringent standards of precision, technical excellence, and operational integrity across its business endeavors.