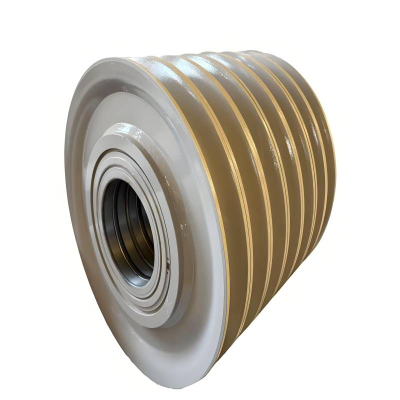

Forging Shaft Sleeve

1.Material:20MnMo/35#

2.Machining accuracy:±0.1mm

3.Mold opening cycle:About 30days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight/Size:Material usage and end-product weight will be derived from the Client’s provided drawings.

7.Craft:Forging

Product Introduction:

The shaft sleeve stands as a critical, wear-resistant core component integrated into hook assemblies, serving as the vital interface that enables seamless connection and relative motion between rotating and stationary parts. Though its structural design appears streamlined, its functional significance is irreplaceable—it is engineered to address three pivotal challenges in heavy-duty operation: minimizing frictional losses between mated components through its precision-machined inner and outer surfaces (often treated with wear-resistant coatings like molybdenum disulfide or chrome plating), dampening operational vibrations to reduce mechanical stress on the entire hook assembly, and maintaining ultra-precise coaxiality of rotating parts. This coaxiality is critical to preventing misalignment, which could lead to uneven load distribution, premature wear, or even catastrophic failure in high-load scenarios. Crafted from high-performance materials such as alloy steel, bronze, or self-lubricating composite polymers—selected based on the hook’s intended application (e.g., heavy construction, mining, or marine lifting)—the shaft sleeve operates as an “invisible cornerstone” of the assembly. It not only shields key components from abrasion, corrosion, and impact but also optimizes power transmission efficiency by reducing energy dissipation. By mitigating wear and tear on adjacent parts (such as the hook shaft and bearing housings) and ensuring stable, low-friction operation, the shaft sleeve directly extends the service life of the entire hook assembly, enhances its long-term operational reliability, and minimizes downtime for maintenance or replacement—proving indispensable for critical lifting operations where safety, durability, and consistent performance are non-negotiable.

Product Advantages:

As a critical mechanical component exclusively engineered for crawler cranes and truck cranes, the shaft sleeve delivers tailored, application-specific advantages to each crane type—benefiting from its customized structural design, high-performance material composition, and precision manufacturing. Across both platforms, it core value lies in four key capabilities: minimizing frictional resistance between mated moving parts via its polished, wear-resistant surfaces, boosting overall mechanical efficiency by reducing energy dissipation, simplifying installation and maintenance through standardized dimensions and user-friendly design, and reliably withstanding extreme heavy loads, dynamic impact stresses, and cyclic operational forces. For crawler cranes—deployed in rigorous, high-intensity scenarios such as large-scale construction, bridge erection, and offshore lifting—the shaft sleeve functions as a rugged "protective shield." Crafted from high-strength alloy steel or heat-treated bronze (reinforced with wear-resistant coatings like tungsten carbide), it boasts exceptional tensile strength, impact resistance, and abrasion durability. These traits enable it to maintain structural integrity even under prolonged heavy-load operation, harsh working environments (e.g., dust, moisture, and temperature fluctuations), and repeated mechanical stress—ensuring stable, uninterrupted performance that minimizes downtime and safeguards critical lifting operations. In contrast, for truck cranes—designed for agility, frequent relocation, and versatile on-site applications—the shaft sleeve serves as a precision "lightweight optimization component." Engineered with a hollow, weight-reduced structure and fabricated from high-strength, low-density composite materials or aluminum alloys (without compromising load-bearing capacity), it contributes to the crane’s overall maneuverability and fuel efficiency. Its low-friction design supports frequent start-stop operations with minimal power loss, while its modular, tool-less assembly allows for rapid inspection and maintenance—critical for meeting tight project schedules and maximizing operational uptime in dynamic job site conditions.

Production Process:

Raw material inspection→Cutting→Forging→Quenched and tempered→Shot peening→Rough turning→UT→CMM/GMM→Cleaning packaging

Packaging And Shipping:

Our dedicated team of quality-focused professionals adheres to a stringent, order-specific quality control protocol—designed to uphold uncompromising standards from production to dispatch for every individual order. Prior to delivery, each product undergoes a multi-step preparation process: it is meticulously cleaned using ultrasonic technology to eliminate microscopic contaminants, machining residues, and surface impurities; correctly labeled with regulatory-compliant tags that include critical details such as batch numbers, technical specifications, traceability codes, and safety certifications; and treated with reliable anti-rust protection tailored to its material composition—metal components receive corrosion-inhibiting coatings or vacuum-sealed moisture barriers, while sensitive parts are wrapped in rust-resistant film to safeguard against oxidation during storage and transit. Following this preparation, we conduct a rigorous follow-up inspection led by certified quality engineers, leveraging precision tools such as digital calipers, coordinate measuring machines (CMMs), and surface roughness testers. This inspection verifies dimensional accuracy, structural integrity, material performance, and compliance with predefined technical benchmarks and international standards (e.g., ISO 9001:2015), with any non-conforming items immediately isolated, documented, and resolved through corrective actions before re-inspection and clearance. Ultimately, the qualified products are professionally packaged using high-performance protective materials: shock-absorbing foam inserts and reinforced cartons mitigate impact damage, moisture-proof liners prevent humidity-related degradation, and tamper-evident seals ensure product integrity. These packaged items are then systematically stored in our well-organized, climate-controlled warehouse—equipped with barcode-enabled inventory management, dust-free storage zones, and real-time environmental monitoring—to maintain optimal condition. The warehouse’s efficient racking system aligns with logistics schedules, ensuring products are readily accessible and fully prepared for prompt, damage-free shipment whenever required by the customer.

Company Strength:

The company has achieved a significant milestone by securing certifications for the ISO 9001 Quality Management System, ISO 14001 Environmental Management System, and ISO 45001 Occupational Health and Safety Management System—all awarded by TÜV Rheinland, a globally renowned and authoritative certification body with a legacy of upholding rigorous industry standards. These certifications are not merely formal accreditations; they represent the company’s unwavering commitment to embedding global best practices into every facet of its operations: strict quality control protocols that ensure consistent product excellence, environmentally sustainable processes (including waste reduction, energy efficiency, and eco-friendly material sourcing) to minimize its carbon footprint, and comprehensive workplace safety measures that prioritize the well-being of every employee. Beyond these foundational certifications, the company’s exceptional management capabilities, customer-centric approach, and technical expertise have garnered widespread recognition from industry leaders across domestic and international markets. It has been repeatedly honored with prestigious accolades, such as “Outstanding Supplier,” “Best Quality Award,” “Reliable Partner of the Year,” and “Sustainable Manufacturing Leader”—awards bestowed by key clients, industry associations, and regulatory bodies alike. These honors serve as tangible proof of the company’s consistent delivery of high-quality products, responsive customer service, and ability to adapt to evolving market demands. Far more than symbols of achievement, these certifications and awards reinforce the company’s strong market reputation, build trust with partners and clients worldwide, and validate its capacity to not only meet but exceed the most stringent expectations of even the most demanding industries. By adhering to globally recognized standards and earning industry recognition, the company has solidified its standing as a trusted, leading player in the sector—positioning itself as a preferred partner for businesses seeking reliability, quality, and responsibility in their supply chains.