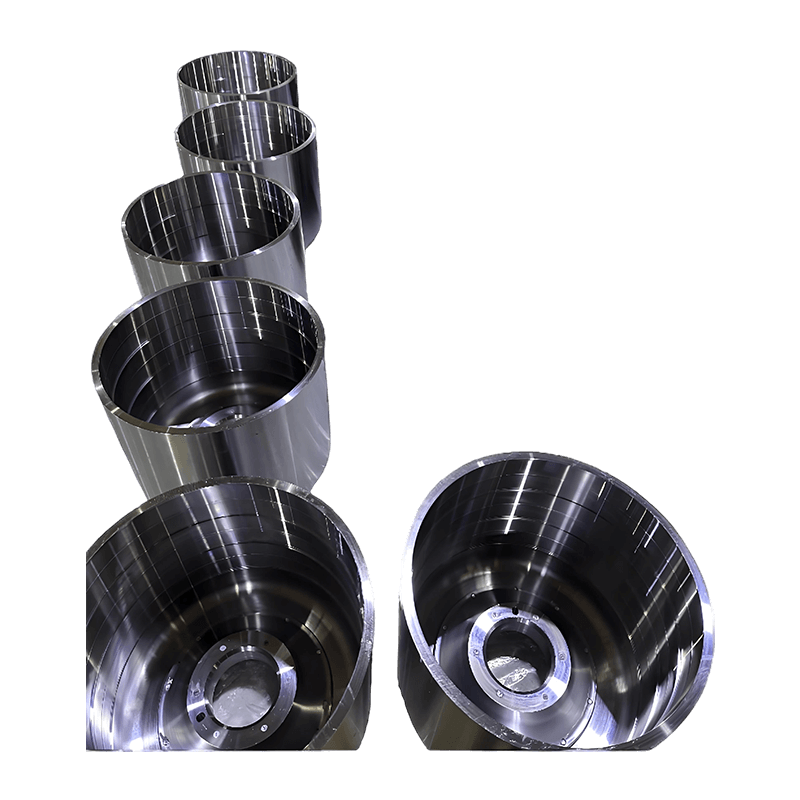

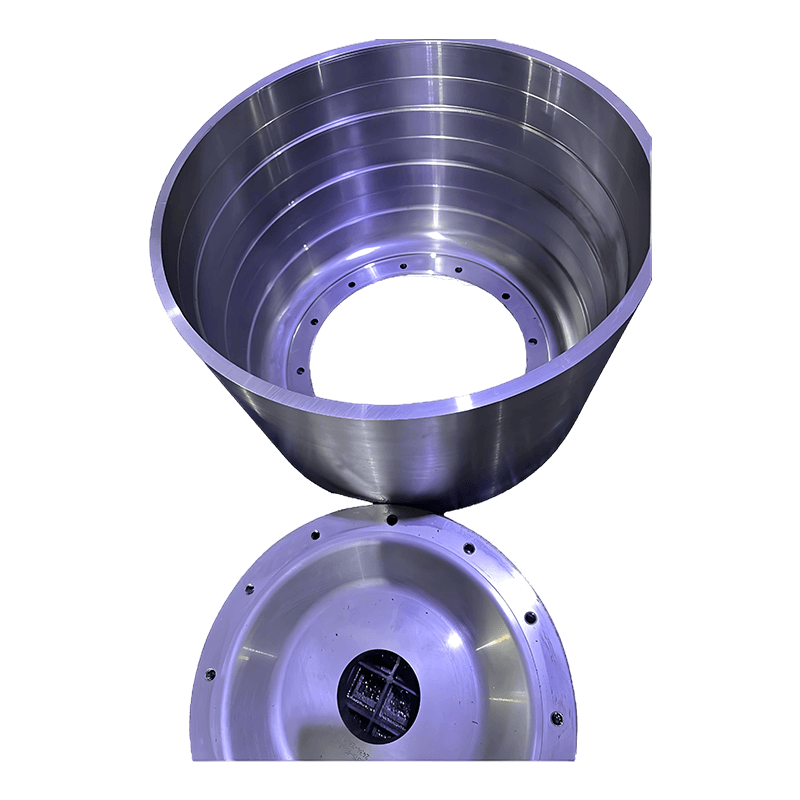

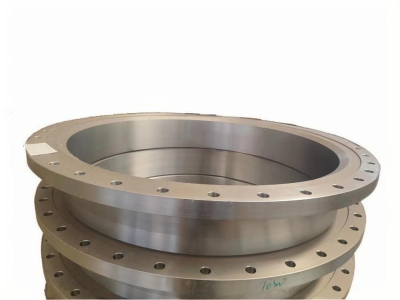

Lightweight Forged Hubs

1.Material:42CrMo

2.Machining accuracy:±0.01mm

3.Mold opening cycle:About 45 days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

7.Craft:Forging

8.Size:Execute custom orders with complete compliance to the drawings provided.

Product Introduction:

Forged hubs feature a dense molecular structure without casting pores, achieving extreme lightweighting that significantly reduces the unsprung mass of new energy vehicles, thereby enhancing range and handling. Forged hubs can adapt to the core needs of electrification and meet heat dissipation requirements. They can also tackle high-torque challenges with extremely strong impact resistance.

Product Advantages:

The hubs in the field of new energy vehicles with their high strength, lightweight, high reliability and customized adaptability, have become one of the core components of drive systems and chassis systems. The forging has no casting defects such as pores and shrinkage porosity inside, and has excellent impact resistance. It can withstand the impact of road bumps and potholes, reducing the risk of tire blowouts and hub fractures. The hub forging process adopts near-net-shape forming technology, reducing the waste of cutting processing and conforming to the "low-carbon and environmental protection" concept of the new energy industry. New energy vehicle hub forgings, through material upgrading, process innovation and structural optimization, have solved the bottlenecks of traditional cast hubs in terms of strength, weight and heat dissipation, and have become key components driving the development of new energy vehicles towards "high performance, long range and intelligence".

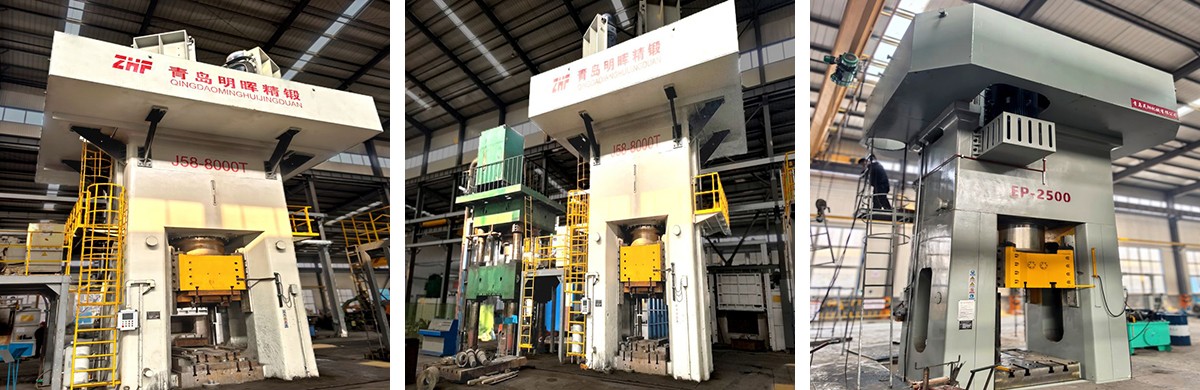

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → CMM/GMM → Cleaning packaging

Packaging and shipping:

Our expert team enforces strict quality control for every order. Before shipment, all products are thoroughly cleaned, clearly labeled, and treated with rust-proof coating. A comprehensive visual inspection follows to guarantee premium quality. Finally, we carefully package and store items in our organized warehouse for immediate dispatch readiness.

Company Strength:

The company's quality management continuously explores digitalization, achieving online management of processes such as issue feedback, nonconformance review, quality traceability, and layered auditing. This has enhanced the standardization and timeliness of issue handling.