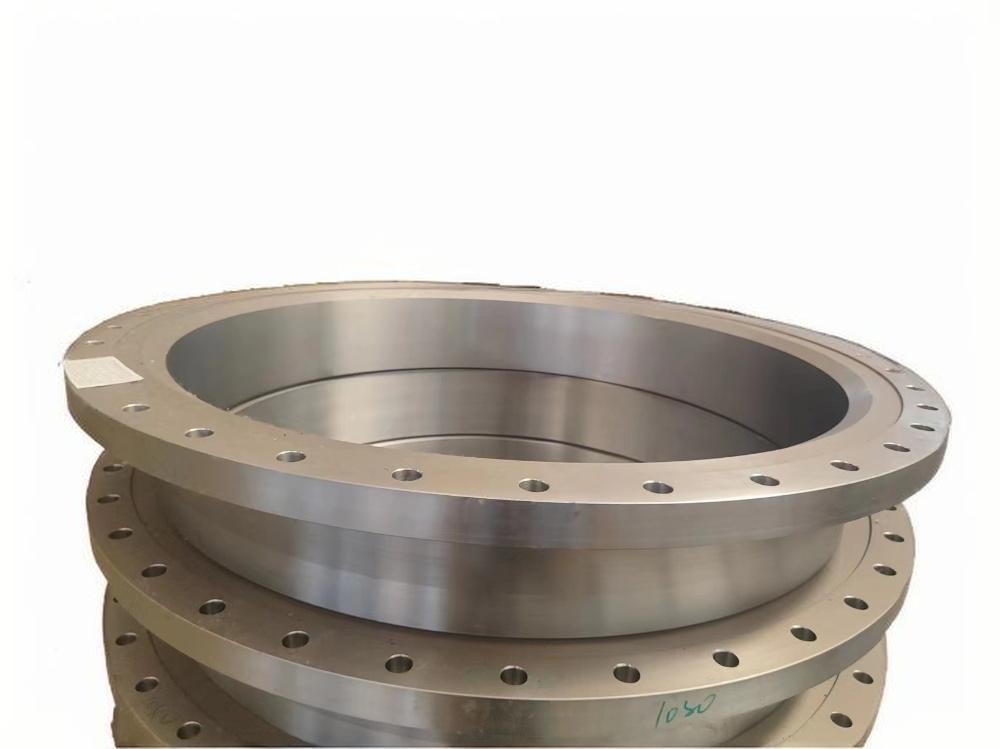

Precision Engineered Excavator Seat Ring

1.Material: Q355

2.Machining accuracy: ±0.1mm

3.Mold opening cycle: About 30 days

4.Customization: Produce customized products based on the drawings.

5.Advantages:

Full-process inspection

Full-process processing capability

Full-range products

6.Weight:Produce customized products based on the drawings.

7.Craft:Forging

Product Introduction:

As a core element enabling flexible operation of excavators, the seat ring in constructing gear excavator forgings performs a essential role in construction. Shaped like a large-diameter ring bearing, it consists of inner and outer rings and rolling elements (balls or rollers) between them, conducting rotation by means of gear meshing. Its predominant facets consist of load bearing, flexible slewing, and component connection.

Product Advantages:

The seat ring in excavators and exclusive constructing tools is a key solid part that connects the greater form (cabin, working device) with the minimize chassis. It performs a core function in supporting the whole machine's weight, transmitting loads, and enabling rotary movements. Its advantages essentially lie in the mechanical advantages of forging, the ability to face up to a couple of thousands simultaneously, special post-forging machining to make positive in form accuracy, low noise and vibration control, ground strengthening techniques to enhance durability, prolonged maintenance-free periods, and fast positioning and installation.

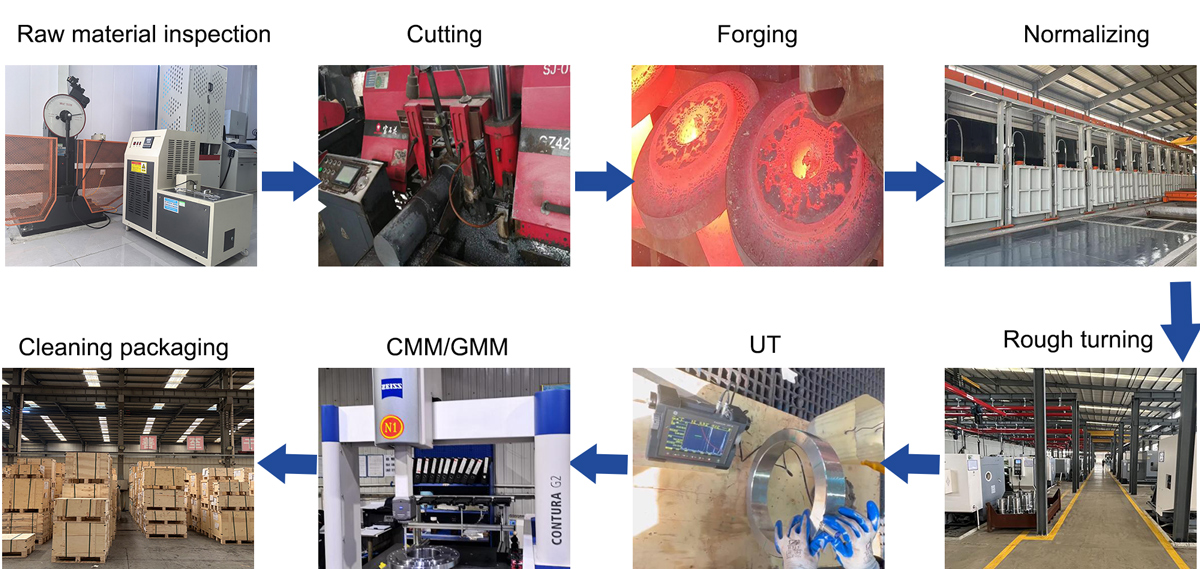

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Rough turning → UT → CMM/GMM → Cleaning packaging

Packaging and shipping:

Before shipment, the merchandise will be cleaned, labeled, and rust-proofed; we will moreover endure seem to be inspection formerly than being finally packed and saved in the warehouse.

Company Strength:

The employer has got certifications for ISO 9001 Quality Management System, ISO 14001 Environmental Management System, and ISO 45001 Occupational Health and Safety Management System from TÜV Rheinland. Its exceptional administration abilities have been identified via global and home enterprise leaders, and it has obtained severa honors such as Outstanding Supplier and Best Quality Award.