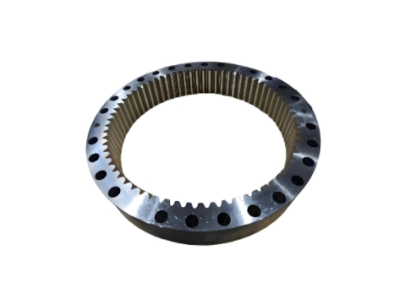

Heavy Duty Transformer Oil Tank Shell

1.Material:Q355

2.Machining accuracy: ±1.5mm

3.Mold opening cycle: About 0 days

4.Craft: Welding

5.Advantages:

Full-process inspection

Full-process processing capability

Full-range products

6. Weight/Size:The material consumption and finished product weight shall be determined based on the customer's drawings.

Product Introduction:

As a key protective component of transformers, the welded transformer oil tank shell has multiple functions: it can not only hold insulating oil, protect the internal core and windings, but also maintain a sealed environment. Its main structure is welded from high-strength steel plates, forming a closed container shape. Through a special welding process, this shell can effectively prevent external moisture and dust from entering. Meanwhile, it can promote the circulation and heat dissipation of insulating oil, thereby ensuring the safe operation of the internal components of the transformer.

Product Advantages:

The outer shell of the transformer oil tank is a core component of the transformer, mainly undertaking key functions such as protecting internal components, insulation, heat dissipation and sealing. The outer shell of this oil tank can resist external influences and provide rigid support for the internal components of the transformer, ensuring that each part remains stable under the action of electromagnetic force and preventing stress deformation from affecting the normal operation of the equipment. As a sealed container, the fuel tank shell can enhance insulation performance: it prevents moisture from entering and oil leakage through sealing, while achieving efficient heat dissipation. This can significantly reduce the failure rate of internal components of the transformer, decrease the downtime losses caused by faults, enhance the long-term reliability of equipment operation, and lower the total life cycle cost.

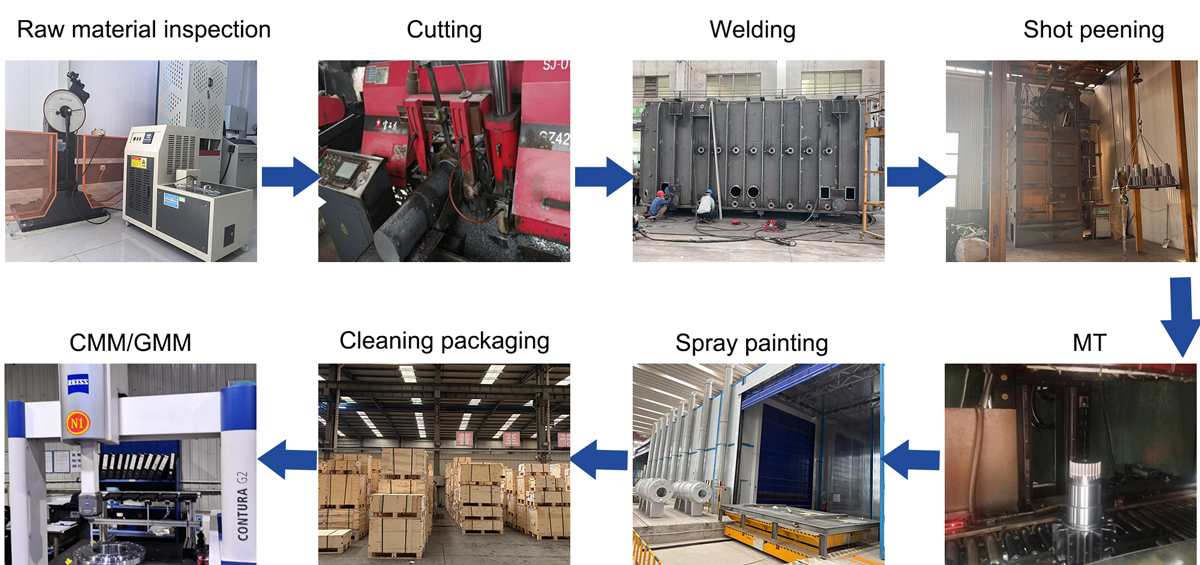

Production Process:

Raw material inspection → Cutting → Welding → Shot peening → MT→Spray painting→ Cleaning packaging →CMM/GMM

Packaging and Shipping:

Our professional team implements a strict quality control process for every order. Before shipment, each product is carefully cleaned, clearly labeled and protected against rust. Subsequently, we will conduct a strict visual inspection to ensure that the product quality is impeccable. Finally, we professionally package the products and store them in a well-managed warehouse to ensure they can be dispatched at any time.

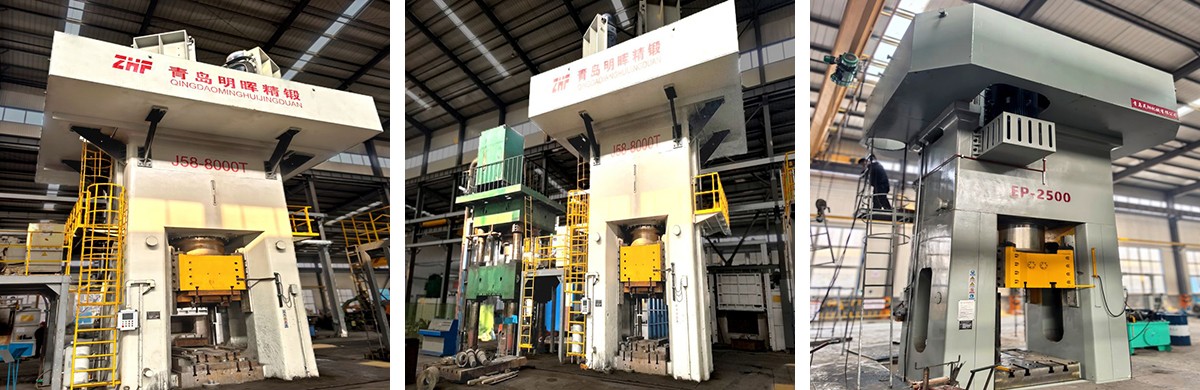

Company Strength:

The enterprise adheres to the principle of "streamlining the entire business process and digitizing the management of all links". Relying on the efficient and high-speed "5G factory" network, enterprises have integrated various data documents from product lifecycle management (PLM) systems, enterprise resource planning (ERP) systems, manufacturing execution (MES) systems, and equipment management systems. Through this integration, the enterprise has achieved digital management of the entire business process, including R&D, production scheduling, work reporting, sequence transfer, delivery, and traceability. The ultimate achievements are reflected in the following aspects: a significant improvement in product research and development efficiency, a marked reduction in the production cycle, and a strong guarantee of the punctuality of customer order delivery.