Durable Transformer Oil Tank Shell

1.Material:Q355

2.Machining accuracy: ±1.5mm

3.Mold opening cycle: About 0 days

4.Customization: Deliver custom-engineered products that meet your exact technical requirements

5.Advantages:

Full-process inspection

Full-process processing capability

Full-range products

6. Weight:The material consumption and finished product weight shall be determined based on the customer's drawings.

7.Craft: Welding

8.Size: Execute custom orders with 100% drawing compliance

Product Introduction:

As a imperative defensive issue of transformers, the welded transformer oil tank shell serves higher than one functions, alongside with containing insulating oil, defending the indoors iron core and windings, and holding a sealed environment. Its essential physique is authentic with the useful resource of welding high-strength metal plates, growing a closed container structure. Through different welding, the shell prevents the intrusion of exterior moisture and dust. Meanwhile, it ensures the impenetrable operation of indoors transformer elements via way of the utilization of facilitating the warmth dissipation of insulating oil with the aid of circulation.

Product Advantages:

The transformer oil tank casing is a essential trouble of a transformer, in particular serving components such as defending indoors components, insulation, warmth dissipation, and sealing. The tank casing can face up to exterior influences and furnish inflexible help for the transformer's indoors components, making high-quality that all elements proceed to be tightly closed under electromagnetic forces and stopping regular operation from being affected by means of potential of functionality of deformation due to stress. As a sealed container, the tank casing enhances insulation performance, prevents moisture and leakage by way of sealing, and allows environment exceptional warmness dissipation. It can notably restrict the failure cost of indoors aspects of the transformer, restriction downtime losses added on with the aid of ability of faults, enhance the long-term operational reliability of the equipment, and reduce life-cycle costs.

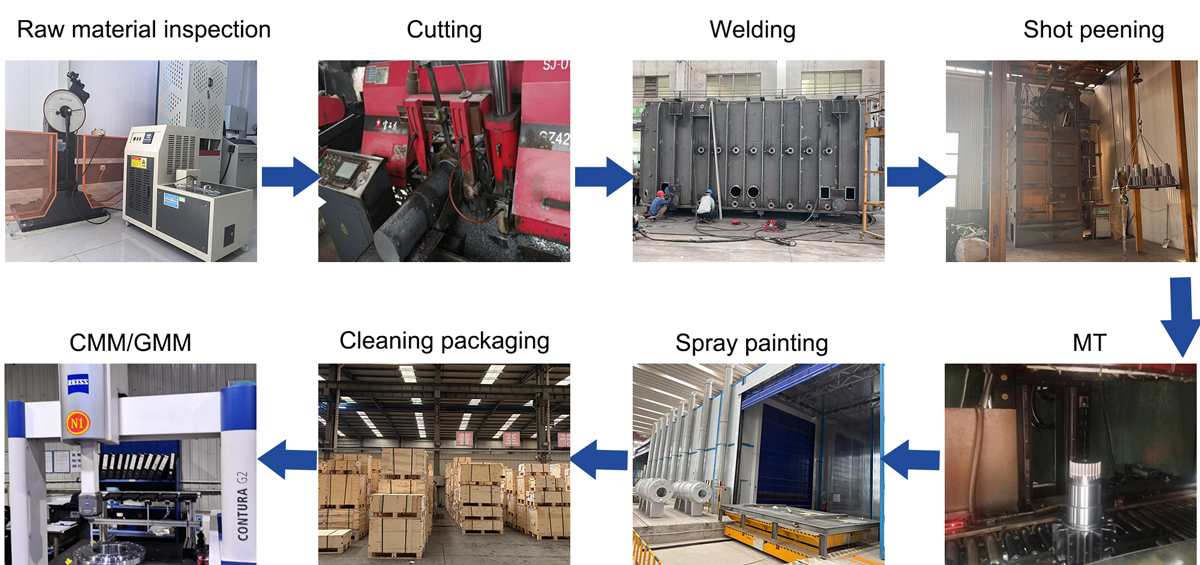

Production Process:

Raw material inspection → Cutting → Welding → Shot peening → MT→Spray painting→ Cleaning packaging →CMM/GMM

Packaging and Shipping:

Our dedicated crew adheres to a strict super manipulate protocol for each and every and each order. Each product is meticulously cleaned, actually labeled, and safeguarded with rust prevention measures in the previous than shipment. Subsequently, a rigorous show up inspection is carried out to make positive flawless quality. Finally, we professionally bundle deal and keep the merchandise in our well-organized warehouse, guaranteeing instant readiness for delivery.

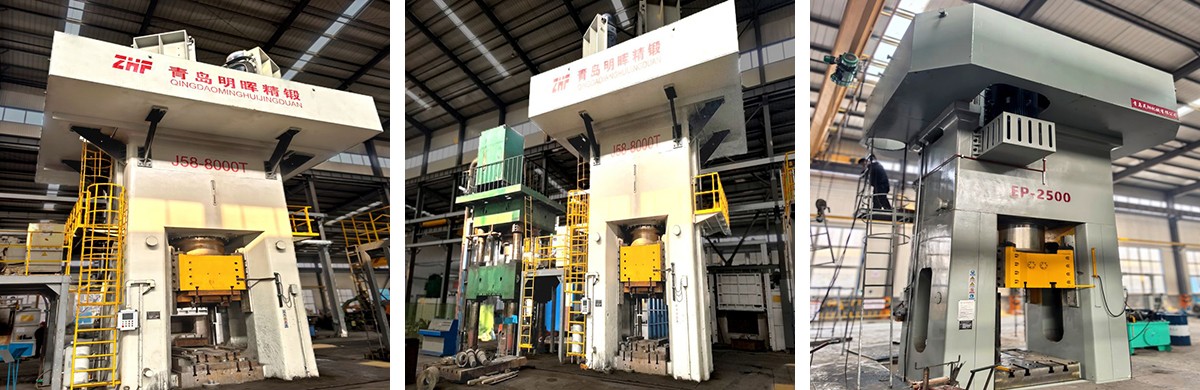

Company Strength:

The business corporation employer adheres to the standards of streamlining all industrial agency techniques and digitizing all procedures. Leveraging the environment high-quality and rapidly "5G factory" internet, it integrates files from the PLM administration system, ERP system, manufacturing MES system, and tools administration system. This integration has enabled digital administration of industrial agency methods such as seem to be up and development, scheduling, work reporting, strategy transfer, shipping, and traceability. As a result, the effectivity of product appear up and enchancment has been drastically enhanced, manufacturing cycles have been shortened, and the punctuality of customer deliveries has been ensured.