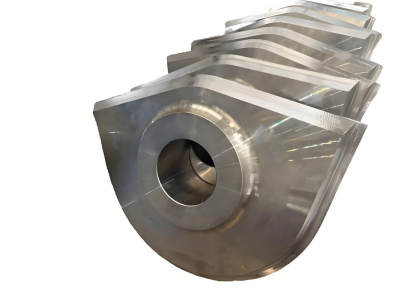

Tank Oil Transformer Shell

1.Material:Q355

2.Machining accuracy: ±1.5mm

3.Mold opening cycle: About 0 days

4.Craft: Welding

5.Advantages:

Full-process inspection

Full-process processing capability

Full-range products

6. Weight/Size:The material consumption and finished product weight shall be determined based on the customer's drawings.

Product Introduction:

Serving as a critical protective component for transformers, the welded transformer oil tank shell performs multiple essential functions. In addition to containing insulating oil, it shields the internal iron core and windings while preserving a hermetically sealed environment. Its primary structure is fabricated by welding high-strength steel plates, resulting in a closed-container design. The diverse welding techniques employed in constructing the shell effectively prevent the ingress of external moisture and dust. Simultaneously, it facilitates the smooth circulation of insulating oil—a process that enhances heat dissipation, thereby guaranteeing the safe and stable operation of the transformer’s internal components.

Product Advantages:

The transformer oil tank casing stands as a vital component of a transformer, fulfilling core functions such as safeguarding internal parts, ensuring insulation integrity, enabling heat dissipation, and maintaining airtight sealing. Engineered to resist external impacts, it provides robust rigid support for the transformer’s internal components—securing all parts firmly in place even under electromagnetic forces and preventing stress-induced deformation that could disrupt normal operation. As a sealed container, the tank casing enhances insulating performance through its airtight design: it effectively blocks moisture ingress, prevents oil leakage, and facilitates efficient heat transfer. These integrated features play a critical role in minimizing the failure rate of the transformer’s internal components, reducing downtime losses caused by malfunctions, boosting the equipment’s long-term operational reliability, and lowering its overall life-cycle costs.

Production Process:

Raw material inspection → Cutting → Welding → Shot peening → MT→Spray painting→ Cleaning packaging →CMM/GMM

Packaging and Shipping:

Our committed team adheres to a stringent quality control process for every order. Prior to shipment, each product is subjected to thorough cleaning, marked with clear labeling, and treated with professional anti-rust protection. Following these preparatory steps, a rigorous visual inspection is carried out to ensure flawless quality standards are met. Finally, the products are professionally packaged and stored in our well-organized warehouse—ensuring they are fully prepared for immediate dispatch whenever delivery is required.

Company Strength:

The company upholds the principles of optimizing all business processes and digitizing every operational procedure. Leveraging the high-efficiency, high-speed "5G factory" network, it integrates data from the PLM system, ERP system, MES, and equipment management system.This seamless data integration enables end-to-end digital management of key business workflows—covering R&D, production scheduling, work reporting, process handover, delivery, and full traceability. As a result, product R&D efficiency has been substantially enhanced, production cycles have been shortened, and the on-time delivery rate to customers has been reliably secured.