Corrosion Resistant Cross Shafts

1.Material:17CrNiMo6-4/18CrNiMo7-6/20CrMnMo

2.Machining accuracy: ±0.1mm

3.Mold opening cycle: About 45 days

4.Customization: Manufacture custom-tailored products that strictly comply with your technical specifications.

5.Advantages:

100% process inspection

One-stop processing capability

Full-range product offering

6. Weight/Size:The calculation of material usage and final product weight shall be governed by the drawings furnished by the Client.

7.Craft:Forging

Product Introduction:

In the petrochemical industry, cross shafts serve as core elements of traditional couplings, especially used to transmit torque and motion between one-of-a-kind axes. They are in special remarkable for not easy working prerequisites requiring compensation for angular deviations, axial displacements, or radial displacements. Their format and fundamental usual overall performance at as quickly as have an have an effect on on the stability, reliability, and security of equipment.

Product Advantages:

In the petrochemical field, the cross shafts is a key element in mechanical transmission constructions (such as giant couplings, go - shaft every day joints, etc.). It is typically speakme used to transmit rotational motion and torque between intersecting shafts. Its layout and common average overall performance proper away have an affect on the transmission efficiency, reliability, and security of the equipment. The go shaft has excessive electrical energy and fatigue resistance. It adopts precision machining processes, sealed and leak - proof designs to stop the leakage of lubricating oil and the intrusion of exterior dust/corrosive media, making tremendous extended - time period dependable operation in the relatively polluted and humid surroundings of the petrochemical industry.

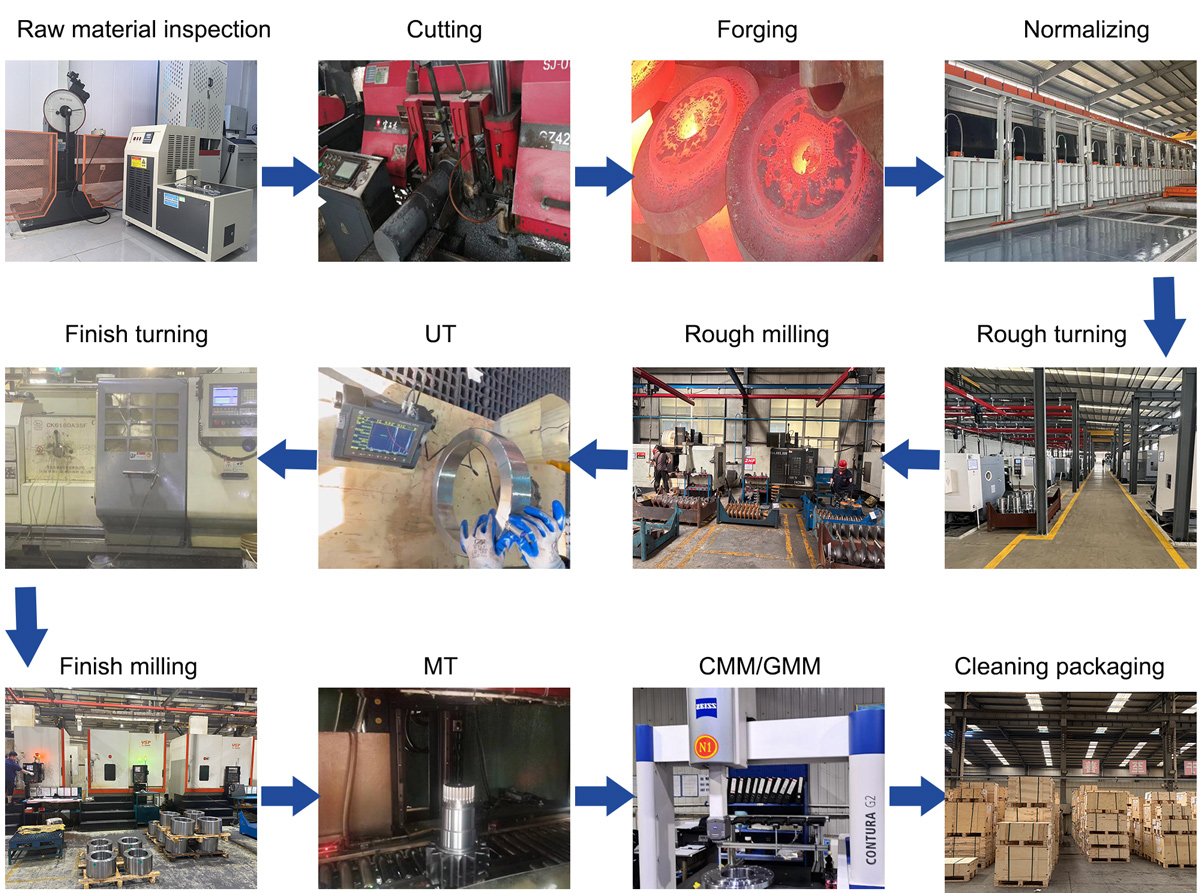

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Rough turning → Rough milling → UT → Finish turning → Finish milling → MT → CMM/GMM → Cleaning packaging

Packaging And Shipping:

Our devoted crew implements rigorous wonderful manipulate protocols for each order. Prior to shipment, all merchandise undergo:

· Thorough cleansing to solid off manufacturing residues;

· Clear labeling for user-friendly identification and traceability;

· Industrial-grade rust-proof coating for long-term protection.

A total considered inspection is then carried out to make sure flawless quality. Finally, merchandise are cautiously packaged and saved in our geared up warehouse, equipped for on the spot dispatch.

Company Strength:

Founded in 1986, Zhangqiu Heavy Forging Co., Ltd. has been committed to a market-oriented technique and a customer-first philosophy for over three decades. With exquisite merchandise and services, the enterprise corporation has generally obtained hobby from home and worldwide clients, forging a route of massive and progressive development. Today, Zhangqiu Heavy Forging consists of 5 organisation divisions: die forging, free forging, ring rolling, precision machining, lifting hooks, and riveting and welding. The company occupies an location of 300,000 rectangular meters, with manufacturing unit constructions overlaying 120,000 rectangular meters and employs over 1,000 physique of personnel members, producing an annual output cost of 1 billion yuan.