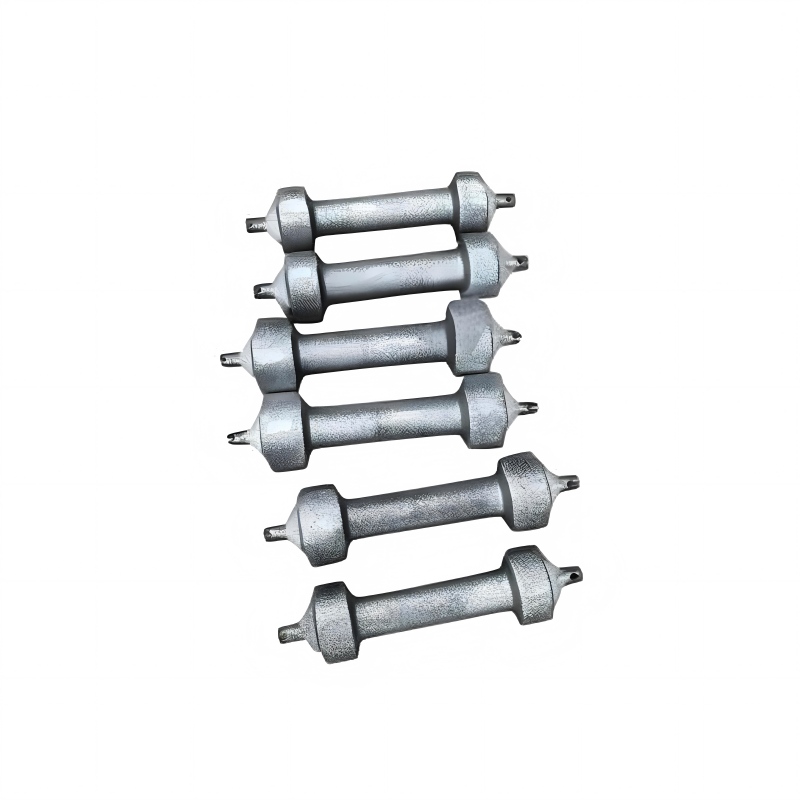

Dumbbell Pins Supplier

1.Material: 30CrMnTi

2.Machining accuracy: ±0.1mm

3.Mold opening cycle: About 45 days

4.Craft:Forging

5.Advantages:

End-to-end inspection

Complete process manufacturing capability

Full-spectrum product line

6. Weight/Size:We will determine the material consumption and finished product weight based on the drawings supplied by the customer.

Product Introduction:

Dumbbell pins designed for coal mining applications play a pivotal role in key mining equipment, including scraper conveyors and swap machines—serving as essential components that guarantee the continuous operation of these devices and facilitate the smooth transportation of materials in underground coal mines.In the coal mining process, scraper conveyors and swap machines are core pieces of equipment tasked with moving coal from the working face to designated collection or transportation points. Dumbbell pins are integrated into each trough body of these conveyors; their primary function is to connect adjacent trough sections, forming an uninterrupted and tightly sealed conveying path. This structural connection not only maintains the stability of the conveyor system during heavy-load operation but also prevents coal or other materials from leaking or getting stuck between trough gaps—directly ensuring the efficient and unobstructed transportation of coal and auxiliary mining materials throughout the mining cycle.

Product Advantages:

Dumbbell pins are integral components of the core trough structure in scraper conveyors used for coal mining equipment. Their design specifications and overall performance directly determine the operational stability, reliability, and mining efficiency of the entire equipment system. These dumbbell pins are engineered with a range of critical properties to meet the demanding conditions of coal mining operations. They boast high mechanical strength and wear resistance to withstand prolonged friction and heavy loads, while their high-precision fit ensures secure and stable connections between trough sections. Additionally, they feature user-friendly characteristics such as quick assembly and disassembly for easy maintenance, along with strong interchangeability that simplifies part replacement. To adapt to harsh underground environments, they also exhibit excellent corrosion resistance and impact load resistance—key traits for enduring moisture, dust, and occasional mechanical impacts.By providing reliable connections between trough components, these dumbbell pins ensure the smooth operation of the scraper chain. This not only enhances the continuity and efficiency of coal transportation from the mining face but also minimizes equipment downtime caused by loose connections or component failures, ultimately extending the service life of the entire scraper conveyor system.

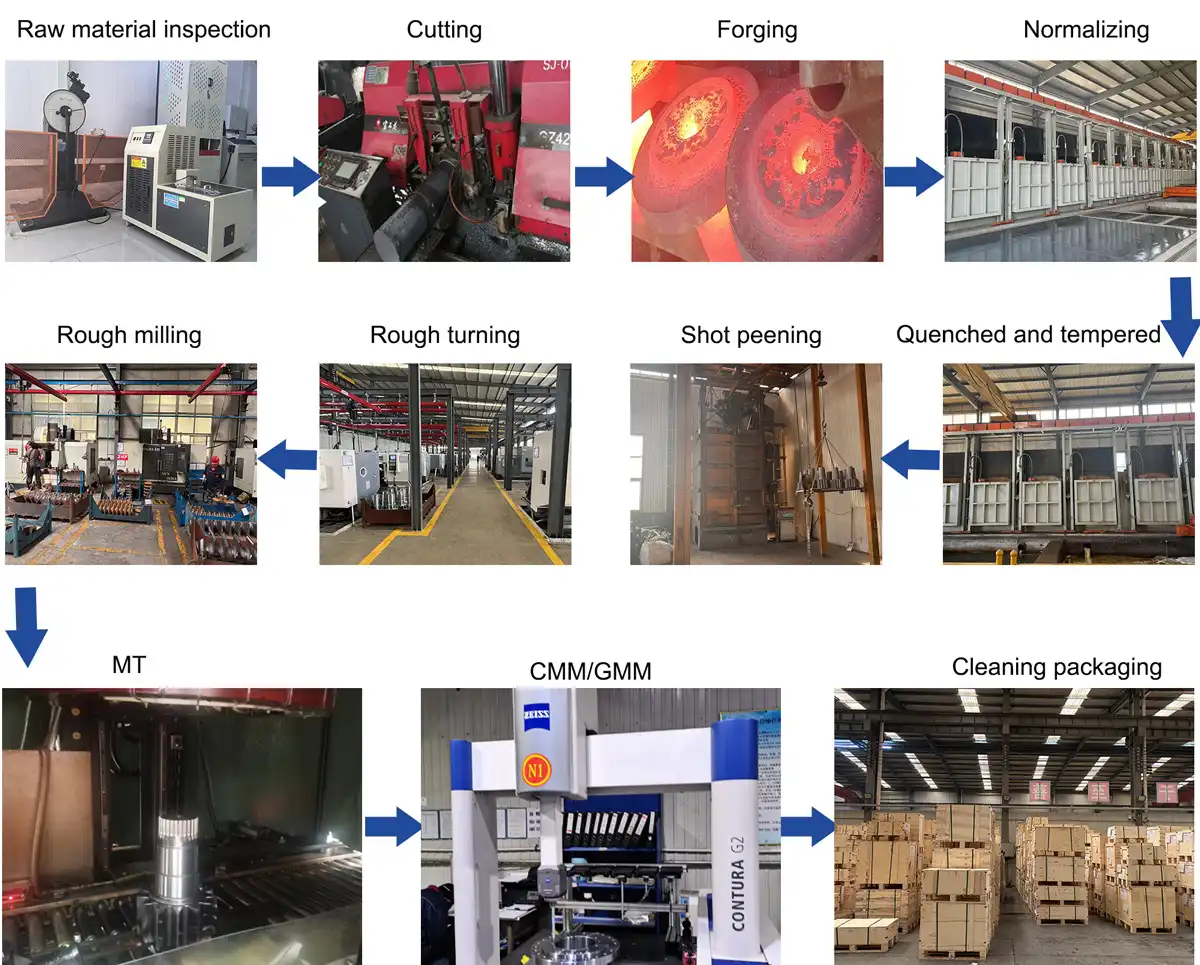

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Quenched and tempered → Shot peening → Rough turning → Rough milling → MT → CMM/GMM → Cleaning packaging

Packaging And Shipping:

Our professional team implements rigorous quality control measures for every order. Prior to shipment, all products undergo thorough cleaning, clear labeling, and rust-proof coating treatment to prevent corrosion during transportation. Following these preliminary steps, a comprehensive and meticulous inspection is conducted—covering dimensional accuracy, material performance, and surface quality—to ensure each product meets the highest quality standards. Finally, we carefully package the qualified products and store them in our well-organized warehouse. This systematic approach guarantees that all items are kept in optimal condition and ready for immediate dispatch once the shipment instruction is received.

Company Strength:

The company is equipped with state-of-the-art inspection and testing equipment, including imported spectrometers, nitrogen-hydrogen-oxygen analyzers, Zeiss metallographic microscopes, Zeiss coordinate measuring machines (CMMs), and M2M ultrasonic phased array flaw detectors. This advanced equipment portfolio enables the company to conduct a comprehensive range of inspections—spanning from the analysis of raw material composition and performance, to the verification of dimensional accuracy, geometric tolerances, and form tolerances of finished products, as well as non-destructive testing (NDT) for internal structural integrity.In essence, the enterprise possesses full-capability inspection support to ensure quality control at every critical stage, from raw material incoming inspection to final product validation.