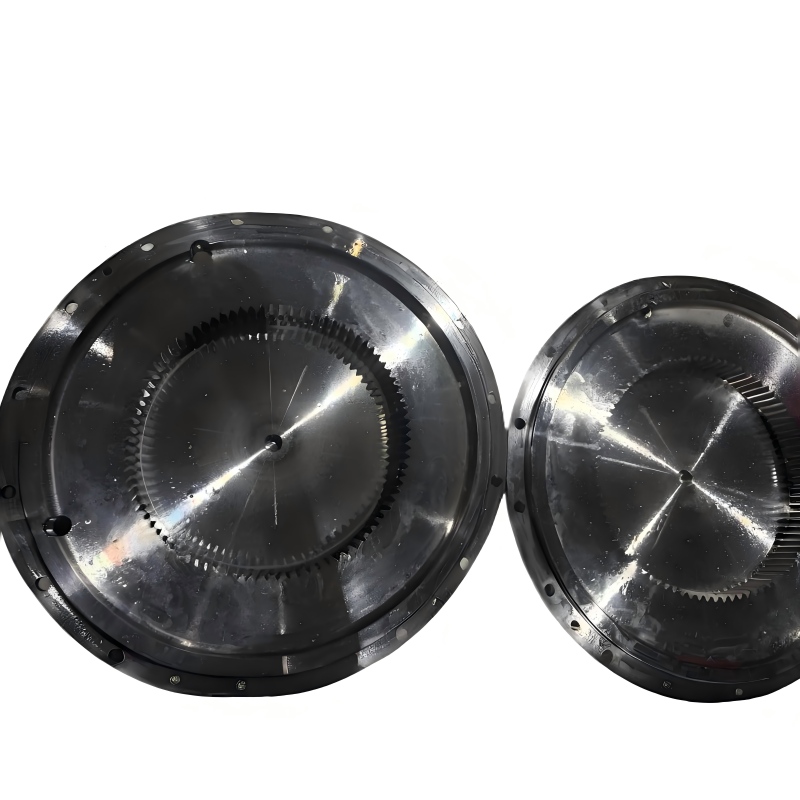

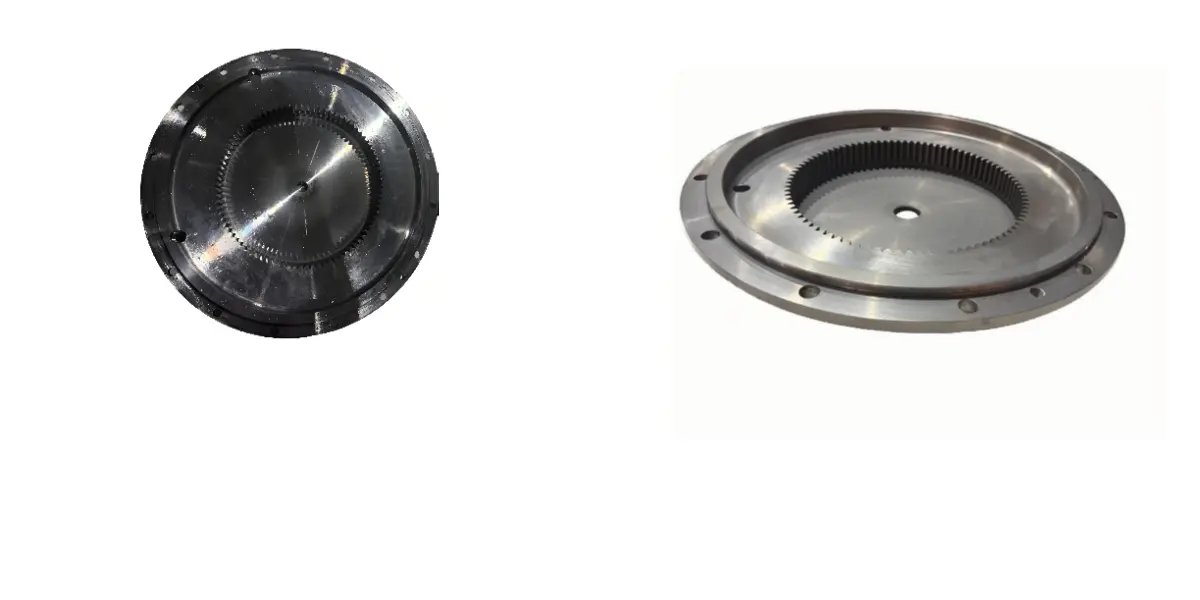

Bearing End Cap Covers

1.Material:42CrMo/45#

2.Machining accuracy:±0.01mm

3.Mold opening cycle:About 45 days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

7.Craft:Forging

Product Introduction:

End covers are critical components in industrial equipment, functioning to seal, protect, and hermetically close openings. Categorized under disc-shaped enclosure parts, they integrate four core functionalities: sealing, protection, support, and connection. Despite their compact size, these end covers serve as the "protective shield" of industrial machinery. Their design and development consistently adhere to three fundamental principles: operational reliability, environmental adaptability, and eco-friendly manufacturing. Looking forward, driven by the advancement of new energy technologies and smart manufacturing, end covers are poised to break new ground in lightweight, intelligent, and environmentally sustainable designs. They will undoubtedly solidify their role as indispensable "industrial guardians" for high-end equipment.

Product Advantages:

End covers, as indispensable components in industrial equipment, offer distinct advantages in four key aspects: effective sealing and protection, structural support and stability, material adaptability, and cost-effectiveness.

Efficient Sealing and Protection

Structural Support and Stability

End covers fabricated from forged steel are capable of withstanding axial loads of up to 20 kN. Their rib-reinforced structural design further enhances resistance to bending and torsion, rendering them ideal for deployment in heavy-duty scenarios like ore grinding mills and large-scale industrial machinery.

Production Process:

Raw material inspection→ Cutting→ Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → Shaping → CMM/GMM → Cleaning packaging

Cleaning and Packaging

Our team will carry out the following procedures:

First, we will thoroughly clean all products, attach appropriate labels, and apply rust-proof treatment to them prior to shipment.

Subsequently, a meticulous visual inspection will be conducted on each item to ensure quality.

Finally, the products will be properly packaged and stored in our warehouse, maintaining full readiness for dispatch.

Company Strength:

Over the past three decades of dynamic development, the company has actively expanded into both domestic and international markets. Its products are widely utilized across multiple sectors, including construction machinery, wind power generation, new energy vehicles, rail transit, petrochemicals, and mining machinery. The company has established in-depth collaborative relationships with world-renowned enterprises in countries such as the United States, Canada, Germany, Italy, Belgium, and Japan, with overseas customer revenue accounting for over 50% of its total. Domestically, it has further forged strategic partnerships with leading high-end equipment manufacturers, including Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. Among its diverse product portfolio, the market share of core forgings for planetary reducers and medium-to-large lifting hook assemblies ranks first in the domestic market.