Welding Excavator Boom

1.Material:35#(ASTM:1035 EN:C35E4 DIN:CK35),20MnMo

2.Mold opening cycle:About 45 days

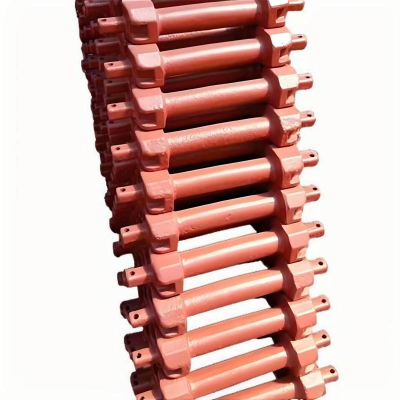

3.Craft:Forging

4.Weight/Size:Material usage and end-product weight will be derived from the Client’s provided drawings.

Product Introduction:

The middle arm base of an excavator's boom—alternatively referred to as the core shaft seat or rear support—is a critical load-bearing component that links the boom and the arm. It plays an essential role in transferring loads, safeguarding stability, and facilitating flexible movement. Looking ahead, as self-sensing lubrication structures and predictive maintenance technologies become more widespread, the core support seat will further evolve toward an integrated model of "self-adaptation – self-repair – extended service life." Consequently, it will emerge as a core competitive element in high-end excavators.

Product Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

Production Process:

Raw Material Inspection → Cutting → Forging → Heat Treatment/Tempering → Shot Blasting → Rough Machining → Ultrasonic Testing (UT) → Final Inspection → Cleaning Packaging

Packaging and Shipping

Our team adheres to a rigorous workflow to ensure all products are shipment-ready, with every detail meticulously addressed. Below is an overview of our process:

First, we carry out three key pre-shipment preparation steps: thorough cleaning to eliminate dirt and debris, affixing clear labels containing critical information, and inspecting the rust-proofing treatment of metal components to ward off corrosion.

Post-preparation, a meticulous inspection is conducted—we check for any defects and test product functionality. Any issues identified will trigger immediate rework until standards are met.

Products that pass inspection are then securely packaged using suitable materials. They are stored in our climate-controlled warehouse, where inventory is systematically organized for rapid retrieval—ensuring products can be dispatched within 2 hours of a shipment request.

Every step of this process is designed to safeguard product quality, streamline logistics, and deliver consistent reliability to our customers.

Company Strength:

Over the previous 30 years of dynamic growth, the organisation has actively accelerated into each home and world markets. Its merchandise are extensively utilized in quite a number fields, which includes building machinery, wind energy generation, new strength vehicles, rail transit, petrochemicals, and mining machinery. The enterprise has installed in-depth collaborations with world-renowned firms in nations such as the United States, Canada, Germany, Italy, Belgium, and Japan, with remote places income accounting for greater than 50% of its complete revenue.