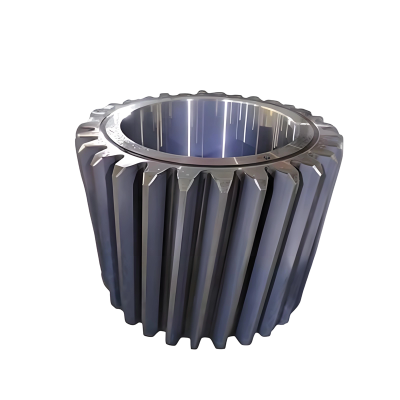

Customization Spindle Shaft

1.Material:42CrMo/40Cr

2.Machining accuracy:±0.01mm

3.Mold opening cycle:About 45 days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

7.Craft:Forging

Product Introduction:

Support shafts stand as indispensable foundational components in mechanical systems, primarily designed to support rotating bodies, transmit loads, maintain motion precision, and minimize frictional wear. Their core attribute lies in delivering stable mechanical support for rotating equipment, thereby ensuring efficient power transmission and reliable structural operation across diverse applications. As cylindrical mechanical parts, support shafts are typically integrated with bearings, seals, and lubrication mechanisms to form a complete support assembly. While their basic structure may appear simplistic, support shafts function as the "backbone" of industrial machinery—encompassing everything from micro-sized shafts (e.g., with a diameter of 2.3mm) used in precision devices to massive ship propulsion shafts extending several meters in length. Their design consistently centers on three core requirements: robust load-bearing capacity, efficient stress transfer, and long-term durability to withstand harsh operating conditions. Looking toward the future, driven by advancements in smart manufacturing and the development of new materials, support shafts will continue to evolve toward lightweight integration, intelligent sensing capabilities, and eco-friendly sustainability. This evolution will enable them to keep pace with industrial innovation, remaining a critical underpinning for the reliable and efficient operation of modern mechanical systems.

Product Advantages:

Support shafts are core components in mechanical systems, offering notable advantages in structural design, material performance, functional versatility, and cost-effectiveness, with their key strengths underscored by technical specifics and real-world applications. Engineered with optimized geometries such as stepped designs and reinforced ribs, they deliver rigid support capable of withstanding radial and axial loads exceeding 20 kN—ensuring stable operation for heavy-duty solid steel variants even under impact or vibration—while precision dynamic balancing keeps vibration within ±0.02 mm for high-speed use cases like 1,500 rpm wind turbine shafts, preventing imbalance-related accuracy loss. Their compact and integrated design shines through models such as CSB’s aluminum shafts, which reach lengths of up to 3,000 mm while minimizing auxiliary support structures, making them ideal for space-constrained applications like robotic arms and compact equipment; dual-function variants also act as structural backbones, eliminating the need for extra supports to reduce installation complexity and costs. Driven by Industry 4.0 advancements, support shafts are poised to evolve with carbon fiber-reinforced composite materials that cut weight by 30% while boosting fatigue resistance, embedded sensors such as stress gauges for real-time deformation monitoring, and laser cladding-enabled remanufacturing that lowers replacement costs by 30% in alignment with circular economy goals—all these upgrades will continue to power the development of high-end mechanical equipment.

Production Process:

Raw material inspection→ Cutting→ Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → Shaping → CMM/GMM → Cleaning packaging

Packaging and Shipping

Our team will conduct thorough pre-shipment preparation for all merchandise: first, we will clean each item, apply clear labeling, and implement professional rust-proofing treatments; we will then carry out a meticulous inspection to ensure product quality meets standards; finally, we will carefully package the products and store them in our warehouse, maintaining them in optimal condition to be fully ready for immediate dispatch.

Company Strength:

Over three decades of dynamic growth, the company has expanded proactively into both domestic and global markets. Its products are widely utilized across key sectors including construction machinery, wind power generation, new energy vehicles, rail transit, petrochemicals, and mining machinery. The company has established in-depth collaborations with world-renowned enterprises from countries such as the United States, Canada, Germany, Italy, Belgium, and Japan, with overseas sales accounting for over 50% of its total revenue. Domestically, it has also forged strategic partnerships with leading high-end equipment manufacturers, including Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. Notably, its core forgings for planetary reducers and medium-to-large lifting hook assemblies hold the top market share in the domestic market.