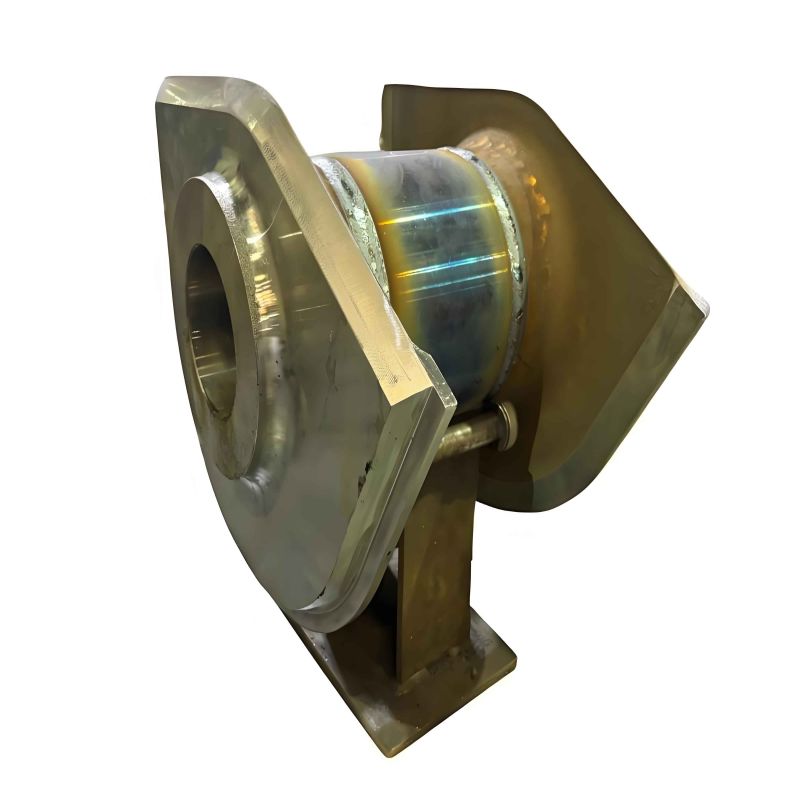

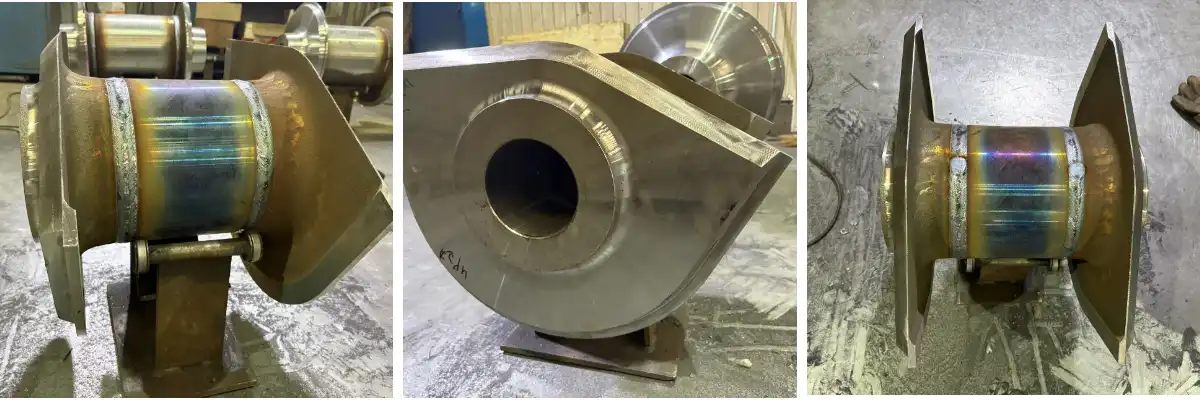

Swing Arm Excavator Parts

1.Material:35#(ASTM:1035 EN:C35E4 DIN:CK35),20MnMo,20#

2.Machining accuracy:±0.5mm

3.Customization: We design and manufacture tailor-made products to your exact technical requirements.

4.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

5.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

6.Craft:Forgin

7.Size:Execute custom orders with complete compliance to the drawings provided.

Product Introduction:

The excavator boom’s support welded assembly—also known as the axle welded assembly, front support base welded assembly, or rear bracket welded assembly—is a critical load-bearing component that serves as the vital connection between the boom and the arm. It plays irreplaceable roles in transmitting heavy loads, maintaining stable balance during operation, and enabling flexible, precise movement of the excavator’s working devices. Looking ahead, as self-sensing lubrication structures and predictive maintenance technologies become increasingly widespread in the industry, the front support welded assembly will undergo further evolution toward an integrated, intelligent model defined by "self-adaptation, self-repair, and service life extension." This technological advancement will not only enhance the component’s performance and reliability but also elevate it to a core competitive differentiator for high-end excavators, driving innovation in the sector.

Product Advantages:

The support welded assembly of an excavator is a critical load-bearing component in the machine’s working system, with its product advantages typically reflected in material innovation, structural design, manufacturing processes, and intelligent optimization—while the core strengths of the excavator boom and arm shaft seat assembly converge in four key aspects: material upgrading, where forged and quenched components are combined with wear-resistant coatings to effectively double the service life; structural innovation, featuring adjustable dimensional configurations paired with modular inner sleeves that enhance both adaptability to diverse working scenarios and overall cost-effectiveness; manufacturing precision, achieved through the integration of robotic welding and specialized positioning fixtures to ensure millimeter-level assembly accuracy and consistent quality; and maintenance convenience, supported by surfacing repair capabilities and a modular replacement design that significantly reduces operational and maintenance costs for end-users. By integrating advanced materials science, structural mechanics principles, and cutting-edge intelligent manufacturing technologies, this assembly has achieved a comprehensive performance leap in terms of high strength, extended service life, and low maintenance requirements, solidifying its role as a key factor in improving the reliability, durability, and operational efficiency of modern excavator working devices.

Forgings + Pipe Fittings Assembly → Welding → Non-Destructive Testing → Cleaning & Packaging → Shipment

Packing and Shipping

Our team is dedicated to delivering products that meet the highest quality standards to our customers, and we’ve established a rigorous, end-to-end process to uphold this commitment:

First, every product undergoes thorough cleaning to eliminate dust, debris, or residual contaminants accumulated during manufacturing or storage. Each item is then affixed with clear, standardized labeling—including product model, batch code, and handling guidelines—to ensure full traceability and transparency across the entire supply chain. Following this, we apply professional anti-corrosion treatments, such as industry-grade protective coatings or vapor corrosion inhibitors, tailored to the product’s material (especially critical for metal components) to prevent rust and degradation during transit and storage. Next, a meticulous quality inspection is conducted by our skilled specialists. This comprehensive check covers structural integrity, functional performance, surface finish, and strict adherence to technical specifications—leaving no detail overlooked. Any identified inconsistencies or defects are addressed immediately, ensuring only products that meet our uncompromising quality criteria move forward. Finally, the certified products are carefully packaged using durable, custom-fitted materials designed to absorb shocks and resist moisture, safeguarding against damage during transportation. They are then securely stored in our climate-controlled warehouse, where inventory is managed with precision to maintain optimal condition. This ensures all items are fully prepared for swift, efficient dispatch the moment orders are confirmed. Through this rigorous, multi-step protocol, we guarantee that every product reaches our customers in pristine condition, ready for immediate deployment.

Company Strength:

With three decades of robust, innovation-driven development, the company has firmly cemented its status as an industry leader through strategic market expansion that spans both domestic and global landscapes. Its diverse, high-performance product portfolio is tailored to serve critical, high-growth sectors—including construction machinery, onshore/offshore wind power generation, new energy vehicles, high-speed rail transit, petrochemical processing, and heavy-duty mining equipment—showcasing its versatility and ability to address the unique, rigorous demands of varied industrial ecosystems. A key competitive strength lies in its extensive international footprint: the company has cultivated long-standing, deep-rooted partnerships with world-renowned enterprises across industrial powerhouses such as the United States, Canada, Germany, Italy, Belgium, and Japan, with overseas sales contributing to over 50% of its total annual revenue—an undeniable testament to its strong competitiveness and trusted reputation in the global marketplace. Domestically, it has forged strategic, mutually beneficial alliances with industry giants including Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear, solidifying its position as a preferred, reliable supplier to China’s top-tier high-end equipment manufacturers. Further amplifying its market edge, the company holds dominant positions in core product segments: its planetary reducer core forgings (critical for precision power transmission) and medium-to-large hook assemblies (essential for heavy-lifting applications) lead the domestic market with the highest market share—a feat underpinned by its advanced technological expertise, uncompromising product quality, and capacity to meet the stringent requirements of high-end industrial applications. By integrating global market penetration, strategic partnerships with industry leaders, and leadership in key product categories, the company has emerged as a reliable, innovative force in the sector—equipped with the capabilities, resources, and market trust to drive sustained growth and shape industry development in the years ahead.