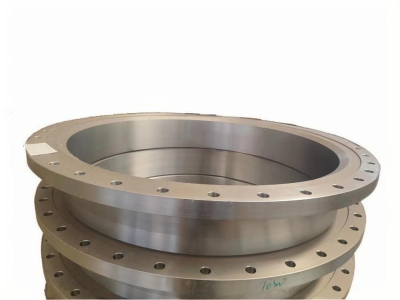

Forging Mining Pin Rails

1.Material:42CrMo

2.Machining accuracy:

Excircle: ±0.01mm

3.Mold opening cycle:About 45days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Craft:Forging

Product Introduction:

For coal mine scraper conveyors and shearers, the pin rail is a vital guiding part that enables their specialized meshing transmission . In computerized fully mechanized mining faces, it combines two core roles: acting as a track for the shearer's movement and as a gear for power transfer—this "dual-function" design is key to its utility . How well the pin rail performs directly affects mining efficiency and equipment safety; similarly, its working condition has a direct bearing on whether the shearer operates stably.

Product Advantages:

The pin rail delivers significantly higher transmission efficiency compared to conventional methods like chain drive . This advantage effectively minimizes energy loss and reduces the shearer’s power consumption—addressing the inherent friction and energy wastage issues of chain drives, which suffer from polygon effect, inter-component friction, and vibration-related losses . In the harsh underground coal mine environment—characterized by high humidity, heavy dust, and intense coal-rock friction—the pin rail’s wear-resistant properties efficiently mitigate abrasion from long-term meshing . This not only extends its service life but also reduces replacement frequency, lowering maintenance demands. Additionally, the pin rail’s reliable operational performance prevents unplanned shutdowns caused by equipment failures, ensuring the shearer runs at a steady speed and boosting both output and efficiency of the working face.

Production Process:

Raw material inspection→Cutting→Forging→Normalizing→Rough turning→UT→Quenched and tempered→Shot peening→MT→Finished turning→Drilling and Tapping→CMM/GMM→Cleaning packaging

Packaging And Shipping:

Our team adheres to a rigorous pre-shipment preparation protocol to ensure product integrity and compliance before dispatch, encompassing five sequential, detail-oriented stages:

First, we conduct thorough cleaning of all merchandise—removing residual machining fluids, dust, and production debris through precision wiping and compressed air blasting. This step is verified via cleanliness testing to eliminate contamination risks that could compromise end-user assembly or performance . Next, standardized labeling is applied to each unit and outer packaging, incorporating critical details such as product model, serial number, batch identifier, material specifications, and handling precautions. We also verify barcode accuracy to facilitate seamless inventory tracking and customs clearance, mitigating regulatory delays . For metal components, targeted anti-rust protection is implemented based on storage duration and transportation requirements. Options include applying rust-inhibiting grease for short-haul shipments, wrapping in VCI (volatile corrosion inhibitor) film for medium-term protection, or sealed container packaging with desiccants for long-distance transport—all executed in low-humidity environments to prevent condensation . A comprehensive pre-shipment inspection follows, utilizing AQL sampling standards to assess dimensional accuracy, surface finish, and functional performance. Inspectors also conduct packaging integrity checks, including simulated drop tests to validate shock resistance, with non-conforming items immediately flagged for rectification . Finally, qualified products are packed with tiered protective materials—such as shock-absorbing foam inserts and corrugated cardboard cartons (or wooden crates for heavy items)—before being systematically stored in a climate-controlled warehouse zone. Here, temperature and humidity are regulated to preserve product condition until formal loading and dispatch, ensuring readiness for transit .

Company Strength:

With over three decades of sustained, robust growth, the company has strategically expanded its global footprint while solidifying its domestic market presence. Its precision-engineered products have become integral to key industrial sectors worldwide—from construction machinery and wind power generation to new energy vehicles, rail transit, petrochemicals, and mining equipment . Globally, it has cultivated long-standing, deep-rooted partnerships with renowned enterprises across the United States, Canada, Germany, Italy, Belgium, and Japan—testament to its adherence to international quality standards. This global outreach is reflected in its financial performance, with overseas revenue contributing over 50% of total earnings, a figure that underscores its successful penetration of international markets . Domestically, it has established strategic alliances with industry leaders including Zoomlion, XCMG, Sany, Lingong, CRRC, Nanjing Gear, and Zhuzhou Gear, positioning itself as a trusted partner for high-end equipment manufacturing. Notably, the company’s core offerings—planetary reducer forgings and medium-to-large lifting hook assemblies—command the top market share in China. This dominance in critical product segments serves as a powerful indicator of its technical leadership and competitive edge in the domestic industrial landscape .