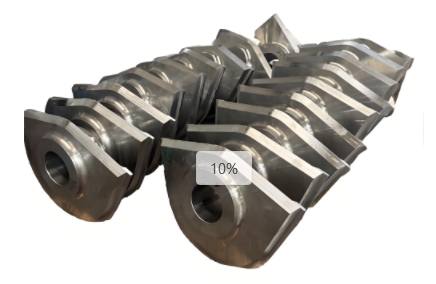

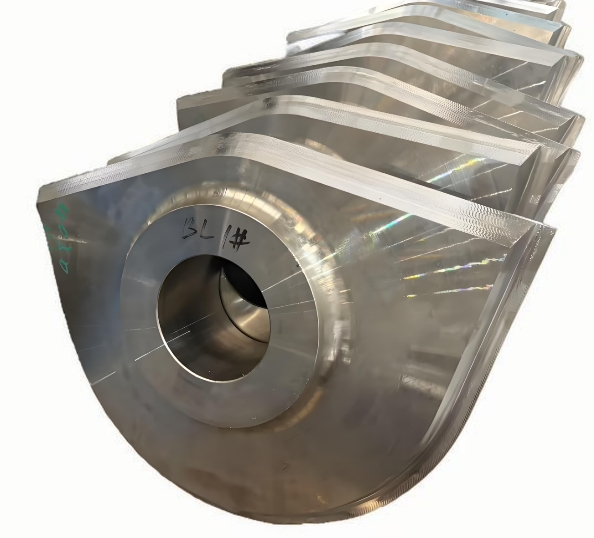

Wear Resistant Rear Support Shaft

1.Material:35#(ASTM:1035 EN:C35E4 DIN:CK35),20MnMo

2.Mold opening cycle:About 45 days

3.Customization: We design and manufacture tailor-made products to your exact technical requirements.

4.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

5.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

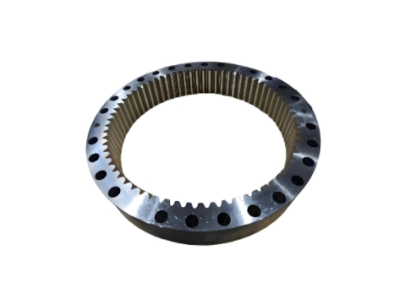

6.Craft:Forging

7.Size:Execute custom orders with complete compliance to the drawings provided.

Product Introduction:

The rear assist seat (also mentioned as the rear shaft seat, rear assist seat or rear support) of the increase of the excavator boom is the core load-bearing component connecting the extend and the boom, taking part in a quintessential function in transmitting loads, making positive steadiness and achieving flexible movement. In the future, with the popularization of self-sensing lubrication buildings and predictive maintenance technologies, the rear assist seat will in a similar way enhance in the route of an built-in route of "self-adaptation - self-repair - prolonged service life", turning into the core competitiveness of high-end excavators.

Product Advantages:

The advantages of its merchandise are commonly mirrored in structural innovation, fabric technology, ease of maintenance and adaptability to a range of scenarios. The characteristic of the mechanical hub: The rear useful resource seat is placed at the rear cease of the bucket arm and is hinged to the make bigger through a pin shaft. It transmits the have an have an effect on on loads all via operation (such as bucket resistance and vibration torque) to the make bigger and chassis structure, and at the equal time serves as the axis for the rotation of the bucket arm, controlling the depth and Angle accuracy of the excavation. The core advantages of the rear help seat of the excavator increase lie in its rather reliable structure: the anti-eccentric load bolstered structure, central symmetrical support, bolstered plate layout, adjustable design, and positioning anti-diversion. The anti-eccentric load layout and the trendy forging manner clear up the cracking problem. Intelligent functions: Adjustable length/Angle to adapt to greater than one scenarios, and embedded sensors for predictive maintenance. Full existence cycle charge optimization: Modular inclined aspects + self-lubrication device reduces safety prices with the aid of the usage of 40%.

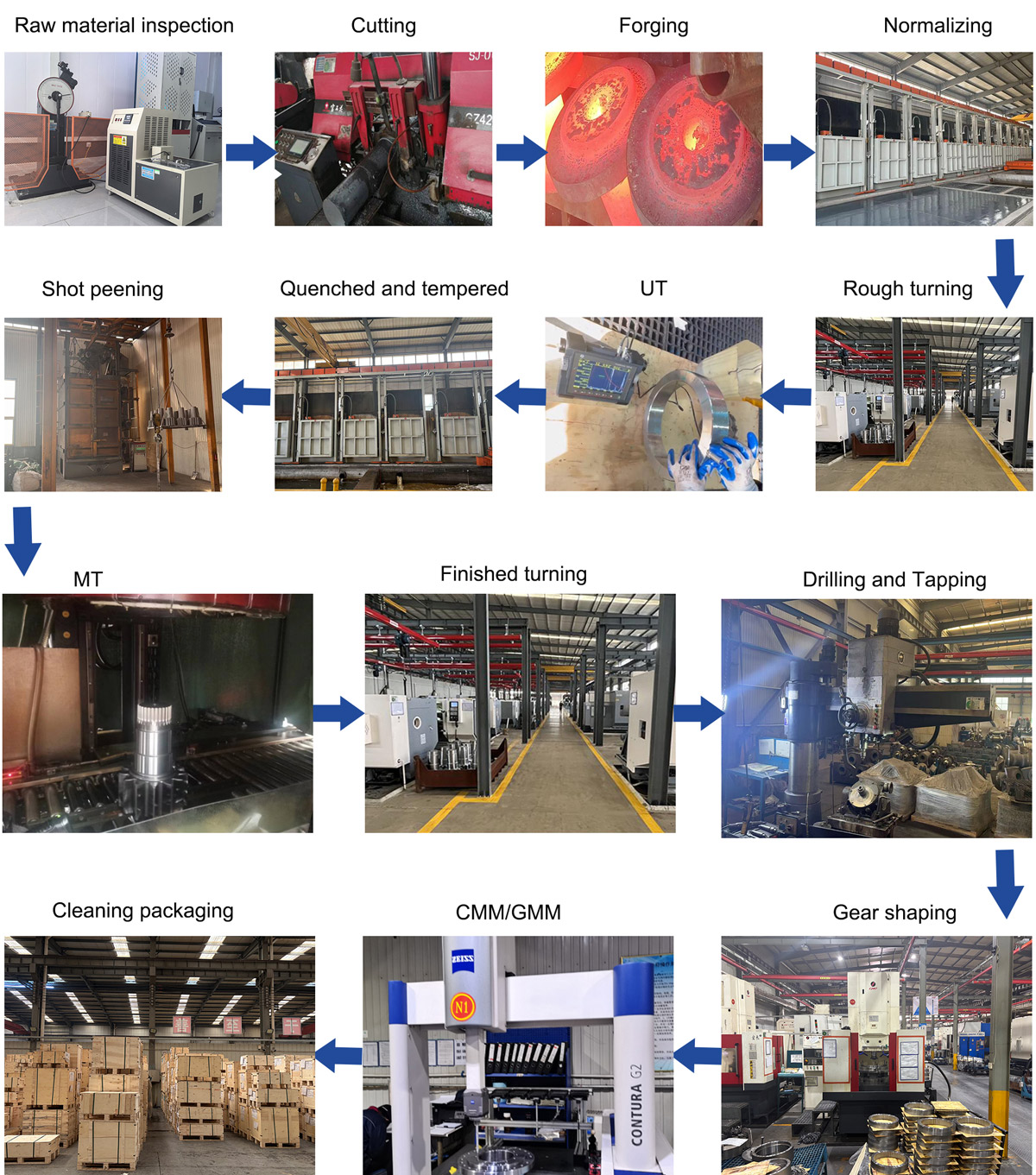

Production Process:

Raw Material Inspection → Cutting → Forging → Heat Treatment/Tempering → Shot Blasting → Rough Machining → Ultrasonic Testing (UT) → Final Inspection → Cleaning Packaging

Our team will:

Clean, label, and take a show up at rust-proofing to all merchandise till now than shipment;

Perform a meticulous exhibit off up inspection

Finally pack the merchandise and maintain them in our warehouse, making exquisite readiness for dispatch.

Company Strength:

Over the preceding 30 years of energetic development, the employer has aggressively extended into every and each and each and every domestic and world markets. Its merchandise are drastically used in fields such as placing up machinery, wind electrical electrical electricity generation, new electrical strength vehicles, rail transit, petrochemicals, and mining machinery. The enterprise has mounted in-depth cooperation with world-renowned agencies in the United States, Canada, Germany, Italy, Belgium, Japan, and great countries, with a approaches away locations capital patron profits accounting for giant than 50%. It has in addition common strategic partnerships with domestic predominant high-end equipment producers such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. Among its products, the market share of planetary reducer core forgings and medium-to-large lifting hook assemblies ranks first in the domestic market.