Forging Cross Shafts

1.Material:17CrNiMo6-4/18CrNiMo7-6/20CrMnMo

2.Machining accuracy: ±0.1mm

3.Mold opening cycle: About 45 days

4.Customization: Manufacture custom-tailored products that strictly comply with your technical specifications.

5.Advantages:

100% process inspection

One-stop processing capability

Full-range product offering

6. Weight/Size:The calculation of material usage and final product weight shall be governed by the drawings furnished by the Client.

7.Craft:Forging

Product Introduction:

Within the petrochemical industry, cross shafts act as critical components for conventional couplings, specifically engineered to transmit torque and mechanical motion between shafts with misalignment. They offer exceptional adaptability to severe operating conditions requiring mitigation of angular deviations, axial shifts, or radial displacements, with their design and functional performance exerting a direct impact on the equipment’s stable operation, reliability, and safety standards.

Product Advantages:

In the petrochemical sector, the cross shaft serves as a critical component in mechanical transmission systems, including commonly used couplings and universal joints. Primarily, it facilitates the transfer of rotational motion and torque between intersecting shafts. Its structural design and overall performance directly influence the transmission efficiency, reliability, and safety of the associated equipment. Boasting high strength and excellent fatigue resistance, the cross shaft is manufactured via precision machining processes. It features a sealed, leak-proof design that prevents lubricating oil leakage and blocks the ingress of external dust and corrosive substances, ensuring long-term reliable operation in the petrochemical industry’s harsh conditions—characterized by high pollution and humidity.

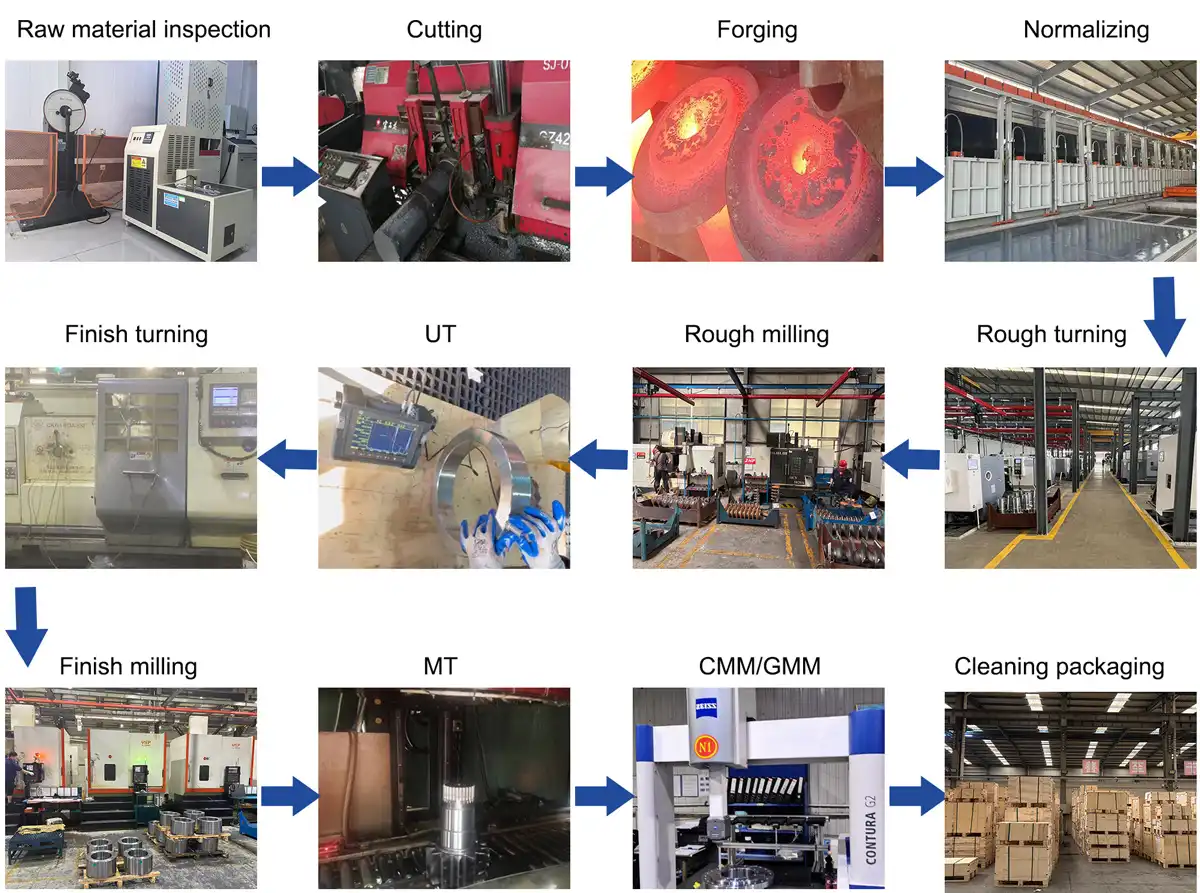

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Rough turning → Rough milling → UT → Finish turning → Finish milling → MT → CMM/GMM → Cleaning packaging

Packaging And Shipping:

To ensure every customer receives products of uncompromising quality, our dedicated team implements rigorous quality control measures for each order. Before shipment, all items undergo meticulous preparation: comprehensive cleaning to wipe away production residues, clear and detailed labeling for hassle-free identification and full traceability, and a durable industrial-grade rust-proof coating to safeguard against corrosion over time. A thorough visual inspection is then performed to guarantee perfection, followed by careful packaging and secure storage in our well-equipped warehouse—so products are always ready for prompt dispatch, ensuring timely delivery and customer satisfaction.

Company Strength:

Established in 1986, Zhangqiu Heavy Forging Co., Ltd. has adhered unwaveringly to a market-driven strategy and customer-centric philosophy for more than three decades. Guided by a commitment to delivering superior products and exceptional services, the company has consistently garnered recognition and trust from clients across domestic and international markets, carving a path of steady innovation and robust growth. Today, Zhangqiu Heavy Forging has evolved into a comprehensive manufacturing enterprise encompassing six core business divisions: die forging, free forging, ring rolling, precision machining, lifting hook production, and riveting & welding. Spanning a total area of 300,000 square meters—with factory buildings covering 120,000 square meters—the company boasts a professional workforce of over 1,000 employees. Leveraging advanced production facilities and mature technical capabilities, it achieves an annual output value of 100 million RMB, solidifying its position as a reliable leader in the heavy forging industry.