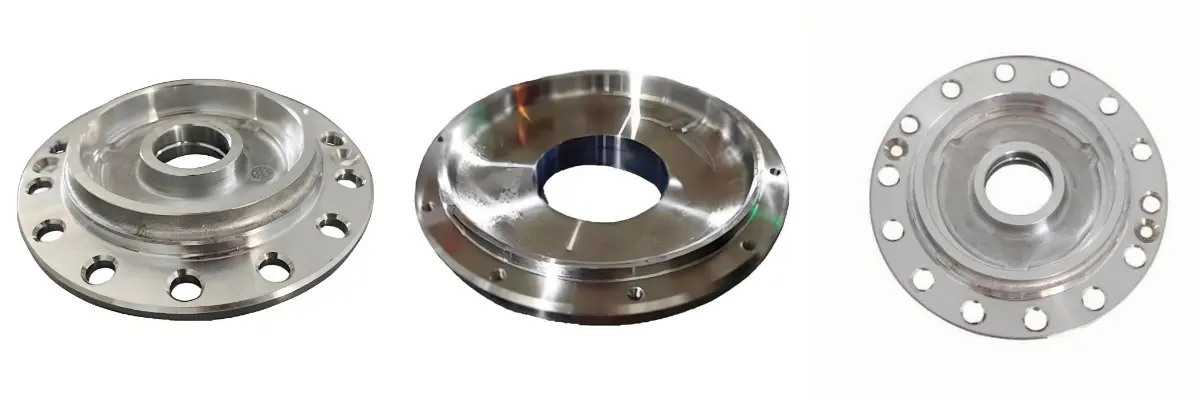

Forging Electric Car Base

1.Material:42CrMo

2.Machining accuracy:

Excircle: ±0.01mm

3.Mold opening cycle:About 45days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Craft:Forging

Product Introduction:

The rotor base stands as a critical load-bearing component of the booster motor in new energy vehicles (NEVs), serving dual core roles: it acts as the precise mounting datum for both permanent magnets and rotor cores, ensuring stable component positioning, while also functioning as a key torque transmission structure that efficiently transfers rotational force throughout the motor system. Dubbed the "backbone" of the motor rotor, its quality—encompassing structural integrity, dimensional accuracy, and material performance—exerts a direct and profound influence on the NEV’s dynamic performance (such as acceleration responsiveness and power output), energy efficiency (critical for extending driving range), and long-term operational reliability. The design and manufacturing of the rotor base demand a delicate balance between three core requirements: robust mechanical strength to withstand high rotational speeds and cyclic stresses, ultra-high machining precision to meet tight tolerances for component alignment, and cost-effectiveness to support large-scale NEV production. This intricate balance makes the rotor base an indispensable link in the localization of core automotive components, playing a pivotal role in advancing the independence and competitiveness of the global NEV industry.

Product Advantages:

While the rotor base is not a core component directly involved in electromagnetic energy conversion, it has evolved into a "fundamental guarantee" for the reliable operation of new energy vehicle motors. It achieves this through key advantages: high-strength support for operational safety, lightweight design to enhance responsiveness, integrated structure to save installation space, vibration and noise reduction for optimized driving experience, and strong environmental resistance to extend service life. Its design level directly correlates with the motor’s power density, energy efficiency, NVH (Noise, Vibration, Harshness) performance, and overall vehicle reliability, positioning it as a critical link in the development of lightweight and highly integrated motors for new energy vehicles.

Production Process:

Raw material inspection→Cutting→Forging→Normalizing→Rough turning→UT→Quenched and tempered→Shot peening→MT→Finished turning→Drilling and Tapping→CMM/GMM→Cleaning packaging

Packaging And Shipping:

Our professional engineering and quality control team enforces a rigorous, full-cycle quality management system tailored to every customer order, ensuring uncompromising standards for rotor base products from production to shipment. Prior to delivery, each rotor base undergoes thorough precision cleaning—utilizing ultrasonic technology to eliminate machining residues, metal shavings, and surface contaminants—laying the groundwork for optimal performance and coating adhesion. This is followed by the application of clear, fully traceable labels that prominently display critical information: part number, batch code, technical specifications, and production date, enabling seamless tracking throughout the supply chain. Next, each unit receives a high-performance rust-proof coating specifically formulated to complement the properties of 42CrMo alloy steel—providing a durable barrier against oxidation and corrosion during long-term storage and cross-border transportation. A comprehensive quality inspection then ensues, combining visual assessment with precision measurements: inspectors verify dimensional accuracy against design tolerances using advanced tools, evaluate surface finish for uniformity and smoothness, check coating adherence and consistency, and confirm structural integrity to eliminate defects such as cracks, burrs, or deformities. Only products that meet strict defect-free quality standards proceed to the final stage.Finally, the qualified rotor bases are carefully packaged in multi-layer protective materials—including shock-absorbing foam inserts, moisture-proof liners, and reinforced cartons—to safeguard against impact, humidity, and external damage during transit. These packaged products are then systematically stored in our well-organized, climate-controlled warehouse, where inventory is managed via a barcode system for easy retrieval. This ensures products maintain optimal condition and are ready for immediate dispatch as soon as order confirmation is received, supporting timely delivery and customer satisfaction.

Company Strength:

To uphold our unwavering commitment to uncompromising quality, the company has made substantial investments in a world-class suite of inspection and testing equipment—equipped with imported high-precision instruments that set industry benchmarks. This includes spectrometers for precise elemental analysis, nitrogen-hydrogen-oxygen analyzers for rigorous chemical composition verification, Zeiss metallographic microscopes for detailed microstructural evaluation, Zeiss coordinate measuring machines (CMMs) for ultra-accurate dimensional accuracy assessment, and M2M ultrasonic phased array flaw detectors for advanced non-destructive testing (NDT). This cutting-edge equipment portfolio endows us with comprehensive, end-to-end testing capabilities spanning the entire product lifecycle: starting with raw material inbound inspection, where we conduct thorough chemical composition analysis, verify the mechanical properties of 42CrMo alloy (such as tensile strength and hardness), and perform strict purity testing to eliminate substandard materials; followed by in-process quality control, which involves micron-level precision measurement of dimensional and geometric tolerances to ensure consistency at every production stage; and concluding with final non-destructive evaluation, a critical step that detects internal defects, micro-cracks, or structural irregularities invisible to the naked eye—preventing potential failures in service. Backed by this robust technical infrastructure, we guarantee that every product not only meets but consistently exceeds international quality standards, delivering unparalleled reliability and performance that instills absolute confidence in our customers.