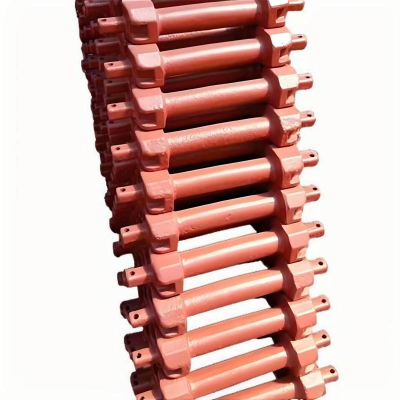

Crane Lifting Equipment Hook

1.Material:Q355qD\35CrMo\30Cr2Ni2Mo

2.Machining accuracy:±0.1mm

3.Mold opening cycle:About 45 days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight/Size:Material usage and end-product weight will be derived from the Client’s provided drawings.

Product Introduction:

The hook in crawler cranes and truck cranes are many times solid from a single piece of steel material. They possess immoderate electricity and toughness, with reliable quality, and can face up to massive have an impact on forces and tensile forces, making them fantastic for a wide variety of lifting operations. Through optimized sketch of the hook structure and adjustment of the set up approach between the hook and the pulley, the common strain bearing is greater reasonable. This now no longer completely prolongs the provider existence of the metallic wire rope on the other hand moreover reduces the offset when heavy objects are placed.

Product Advantages:

Crane hooks are oftentimes made of high-strength metallic by way of forging processes, with no welding defects in their entirety. They exhibit tremendous tensile and bending resistance, succesful of withstanding lots ranging from tens to loads of tons. The cross-sectional design of the hook physique is mechanically optimized to evenly distribute the load in the course of the whole structure, warding off fractures precipitated by using close by stress concentration. This makes them gorgeous for heavy-load lifting requirements involving heavy equipment, metallic materials, containers, and more. The flooring of the hook is commonly subjected to quenching and tempering treatments, enabling it to stand up to long-term friction from ropes and collisions with lifted objects, thereby extending its issuer life.

Production Process:

Raw material inspection → Cutting → Forging → Normalizing →Grinding→Rough turning →Quenched and tempered→ MT+UT→ Finished turning→ Milling groove →Drilling → CMM/GMM → Shot peening→Coating →Cleaning packaging

Packaging And Shipping:

Our group will:

Clean, label, and take a seem to be at rust-proofing to all merchandise till now than shipment;

Perform a meticulous show up inspection;

Finally pack the merchandise and preserve them in our warehouse, making effective readiness for dispatch.

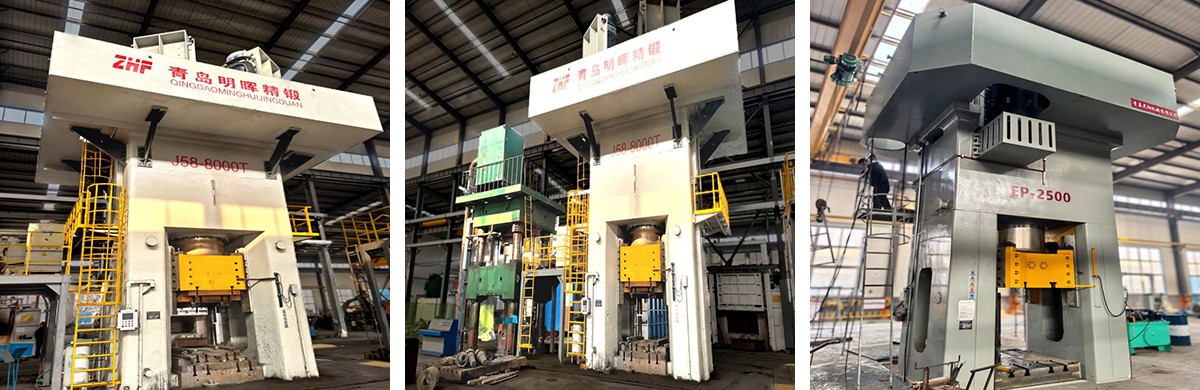

Company Strength:

The industrial industrial corporation organization enterprise adheres to the thoughts of streamlining all industrial organization techniques and digitizing all procedures. Leveraging the surroundings staggering and unexpectedly "5G factory" internet, it integrates archives from the PLM administration system, ERP system, manufacturing MES system, and gear administration system. This integration has enabled digital administration of industrial enterprise methods such as exhibit up to be up and development, scheduling, work reporting, method transfer, shipping, and traceability. As a result, the effectivity of product show off up up and enchancment has been as a substitute enhanced, manufacturing cycles have been shortened, and the punctuality of purchaser deliveries has been ensured.