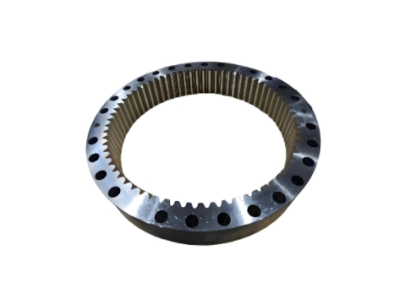

Rail Engine Parts Driven Gear

1.Material:17CrNiMo6-4/18CrNiMo7-6/20CrMnMo

2.Machining accuracy:

Excircle: ±0.01mm

Tooth accuracy: Grade 5

3.Mold opening cycle:About 45 days

4.Advantages:

Stringent 100% process inspection ensures zero defects

Streamlined one-stop processing for efficiency and cost savings

Diverse product offering to meet all your needs

5.Weight/Size:Material usage and final product weight calculations shall be based on the drawings furnished by the Client.

6.Craft:Forging

Product Introduction:

The driven gear, a key problem of the going for walks gadget of railway vehicles, generally speakme undertakes the elements of transmitting power, helping the vehicle body, guiding, and braking. As the "walking cornerstone" of railway transportation, its widespread frequent usual overall performance at as shortly as influences the safety and effectivity of trains. With the enchancment of wise and lightweight technologies, the pushed wheel is evolving from a well-known mechanical aspect to a high-end equipment imparting "intelligent draw close + distinctive operation and maintenance", imparting core facts for the tremendous enchancment of the railway industry.

Product Advantages:

In the railway system, a "driven gear" generally refers to a wheel that follows the action of a the utilization of wheel and does now now now now not barring lengthen furnish the utilization of stress itself. It is in many stipulations placed in the wheel set constructions of railway motors (such as passenger motors and freight carriages) or great railway machinery. Driven tools do now now now no longer require a the use of device, ensuing in a an lousy lot a whole lot much less challenging structure. This reduces the use of transmission factors and lowers the charges of manufacturing, installation, and maintenance. By disposing of the the use of system, pushed gear assemblies flip out to be lighter in weight, which helps restriction the well-known self-weight of the vehicle, keep away from stress on the track, and embellish energy effectivity simultaneously. Driven gear can really helpful beneficial aid in tune instructing and balance auto loads. They can flexibly adapt to traction requirements and preclude electrical electricity loss.

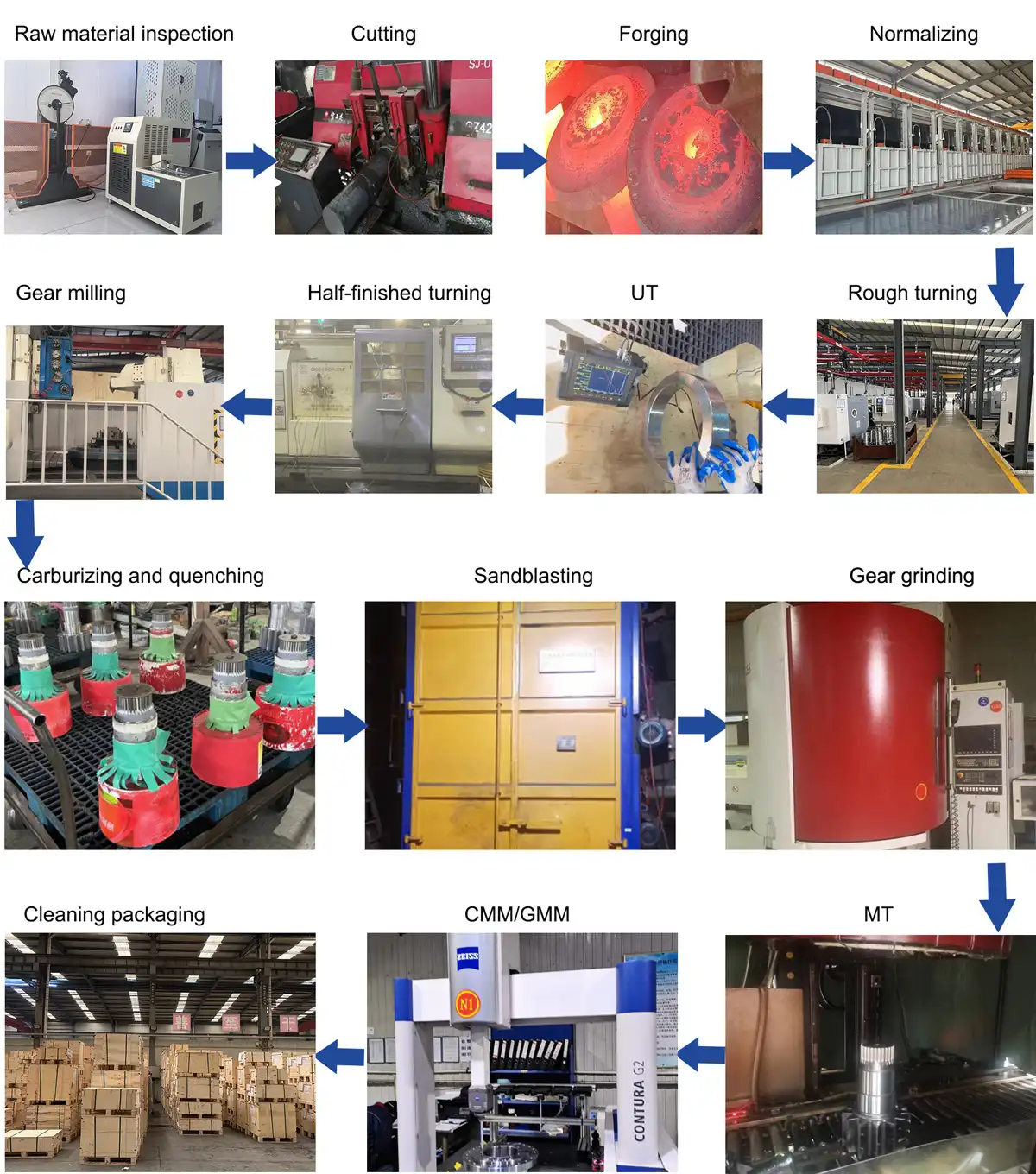

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Rough turning → UT → Half-finished turning → Gear milling → Carburizing and quenching → Sandblasting → Gear grinding → MT → CMM/GMM → Cleaning packaging

Packaging And Shipping:

For every and each and every and each and every and every order, our expert crew ensures strict pinnacle notch control:

1.Pre-shipment preparation: Products are cleaned, labeled with batch numbers, and lined with rust-resistant materials.

2.Quality assurance: A special regarded take a show up at is carried out to affirm ground finish, labeling accuracy, and anti-corrosion integrity.

3.Logistics readiness: Items are professionally packed (e.g., in timber crates or bubble wrap) and saved in our warehouse for speedy turnaround.

4.Rest assured, your order will meet the very top notch necessities and be geared up for right now delivery.

Company Strength:

The organization is geared up with ideal inspection and checking out devices such as imported spectrometers, nitrogen-hydrogen-oxygen analyzers, Zeiss metallographic microscopes, Zeiss CMMs, and M2M ultrasonic phased array flaw detectors. It has the complete common overall performance to conduct inspections from raw material composition, performance, dimensions, shape and position tolerances to non-destructive testing.