Forged Rear Support Shaft For Excavators

1.Material:35#(ASTM:1035 EN:C35E4 DIN:CK35),20MnMo

2.Mold opening cycle:About 45 days

3.Customization: We design and manufacture tailor-made products to your exact technical requirements.

4.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

5.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

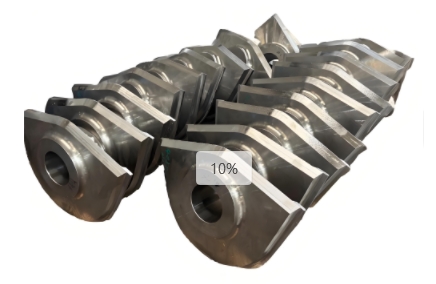

6.Craft:Forging

7.Size:Execute custom orders with complete compliance to the drawings provided.

Product Introduction:

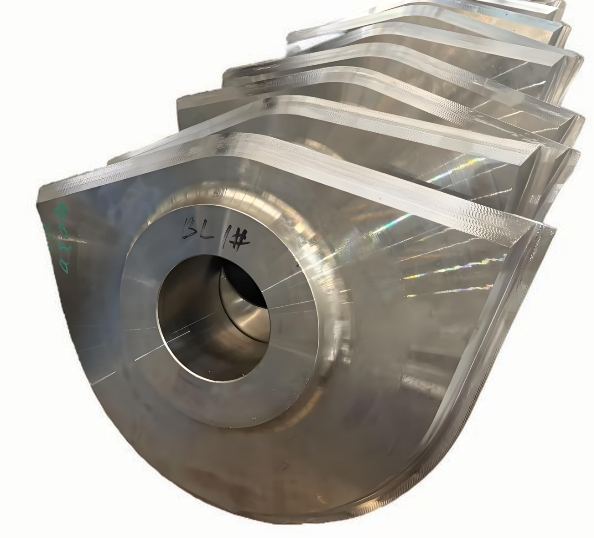

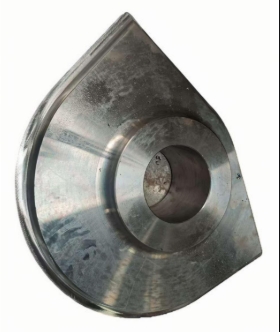

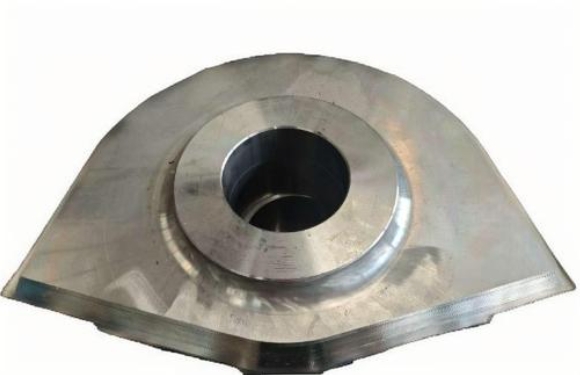

The rear arm base of an excavator's boom—alternatively referred to as the rear shaft seat, rear bearing seat, or rear support—is the core load-bearing issue that connects the increase and the arm. It plays a pivotal role in load transmission, making sure secure operation and enabling bendy movements. Looking ahead, as self-sensing lubrication buildings and predictive upkeep applied sciences turn out to be extra widespread, the rear help seat will similarly evolve towards an built-in machine described by means of "self-adaptation, self-repair, and prolonged provider life." This development will make it a key aggressive function of high-end excavators.

Product Advantages:

The product benefits lie in structural innovation, superior materials, handy maintenance, and adaptability to numerous scenarios. As a mechanical hub, the rear help seat is placed at the bucket arm's rear end, hinged to the growth by means of a pin. It transmits operational masses (bucket resistance, vibration torque) to the increase and chassis, whilst appearing as the bucket arm's rotation axis to manage excavation depth and perspective precision. Its core strengths encompass excessive reliability: anti-eccentric load reinforcement, central symmetric support, stiffened plates, adjustability, and anti-diversion positioning. The anti-eccentric plan and precision forging forestall cracking. Intelligent features: adjustable length/angle for multi-scenario use, plus embedded sensors for predictive maintenance. Full lifecycle value effectivity is executed through modular put on components and self-lubrication, slicing upkeep prices through 40%.

Production Process:

Raw Material Inspection → Cutting → Forging → Heat Treatment/Tempering → Shot Blasting → Rough Machining → Ultrasonic Testing (UT) → Final Inspection → Cleaning Packaging

Our team will undertake the following tasks with great care:

Thoroughly clean, label, and observe rust-proofing remedies to all merchandise prior to shipment;

Conduct a meticulous, multi-point inspection to make sure most suitable quality;

Professionally bundle the gadgets and save them in our warehouse, retaining them in pristine circumstance and entirely organized for well timed dispatch.

Company Strength:

Over the preceding 30 years of full of existence development, the agency has aggressively extended into every and each and every and each and each and every domestic and world markets. Its merchandise are appreciably used in fields such as placing up machinery, wind electrical electrical electrical electricity generation, new electrical electrical energy vehicles, rail transit, petrochemicals, and mining machinery. The organisation has mounted in-depth cooperation with world-renowned firms in the United States, Canada, Germany, Italy, Belgium, Japan, and gorgeous countries, with a strategies away areas capital customer earnings accounting for massive than 50%. It has in addition accepted strategic partnerships with domestic predominant high-end tools producers such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. Among its products, the market share of planetary reducer core forgings and medium-to-large lifting hook assemblies ranks first in the domestic market.