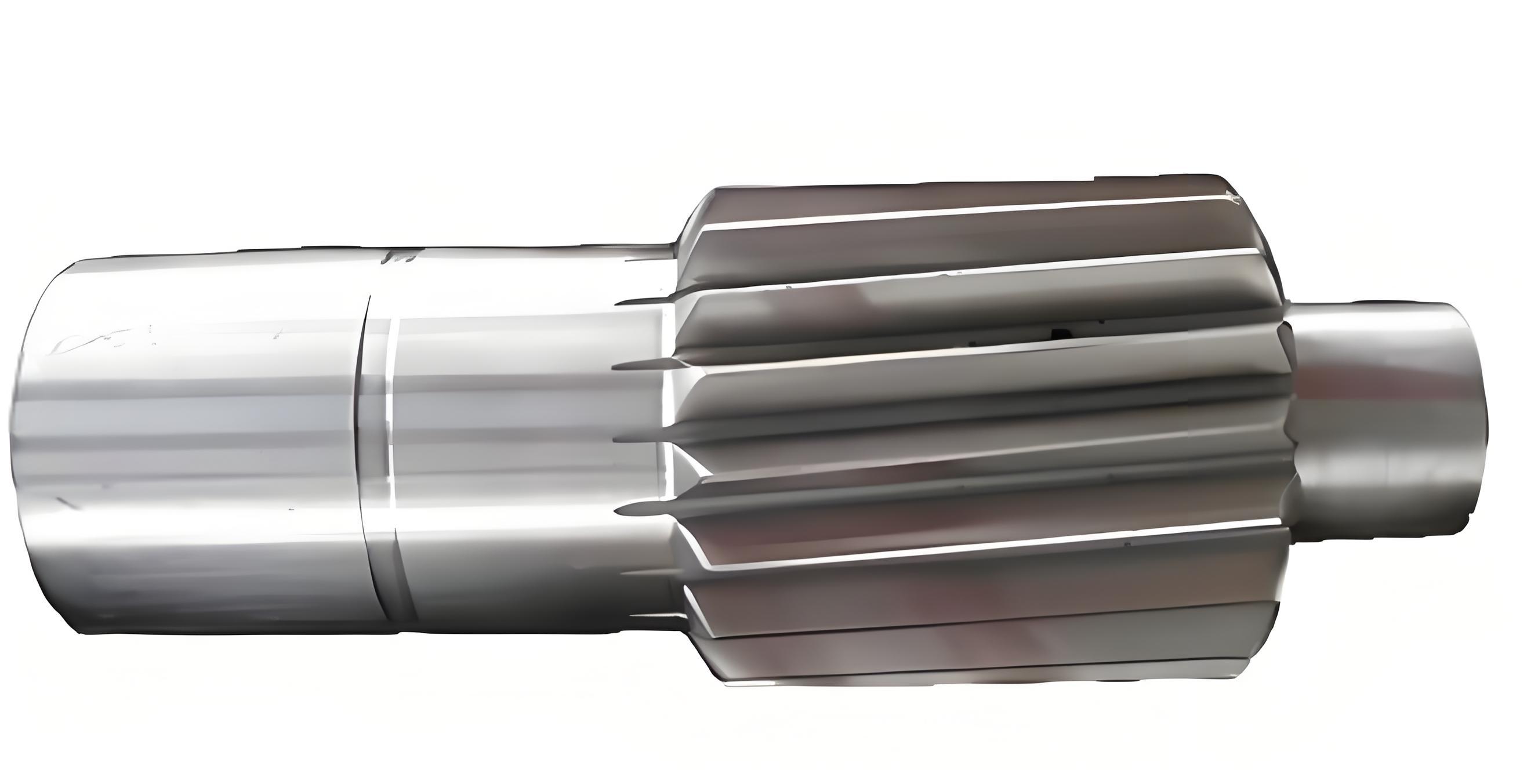

Wear Resistant Planetary Shaft

1.Material:42CrMo

2.Machining accuracy:±0.01mm

3.Mold opening cycle:About 45 days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

7.Craft:Forging

Product Introduction:

Planetary shafts are the core aspects of planetary equipment transmission structures and are key factors in precision mechanical transmission devices. It achieves energy transmission, pace conversion and torque amplification by means of helping planetary gears, and is extensively used in high-precision and high-load fields such as automobiles, development equipment and aerospace. Planetary shafts are the "skeleton" of planetary tools transmission systems. Their cost is mirrored in the following aspects: Function: high-torque velocity exchange and load dispersion; Performance: attaining ultra-long carrier lifestyles and reliability via material/process optimization (such as carburizing and quenching, and manipulate of dispersed carbines); evolution: evolving closer to intelligence, lightweight, and remanufacturing, turning into the core provider of high-end tools transmission systems.

Product Advantages:

As the core helping factor of the planetary tools transmission system, the planetary shaft, with its special structural format and fabric method innovation, has proven enormous benefits in more than one industrial fields, providing energy distribution and coaxial design. The planetary axis achieves strength distribution by way of aiding a couple of planetary gears (usually three to 6), evenly distributing the load to every planetary tools and growing the load-bearing potential with the aid of 30% to 50% (compared with the normal single-point help structure). Meanwhile, the enter shaft and output shaft undertake a coaxial layout, which considerably saves space, decreasing the gadget extent through 50% and the weight by using 30%. It is appropriate for space-constrained situations such as car gearboxes and robotic joints. Compact built-in design, wear-resistant strengthened structure, excessive transmission effectivity (90-99%), variable velocity flexibility and excessive torque, excessive precision and low noise, appropriate for precision laptop equipment and industrial robots. The core price of the planetary axis lies in reaching strength diversion via structural innovation, breaking via the restrict of lifespan via cloth and system technology, and adapting to the needs of more than one eventualities via useful integration. With the popularization of light-weight substances and shrewd sensing technology, it is evolving in the direction of the route of "self-perception - self-adaptation - repairability".

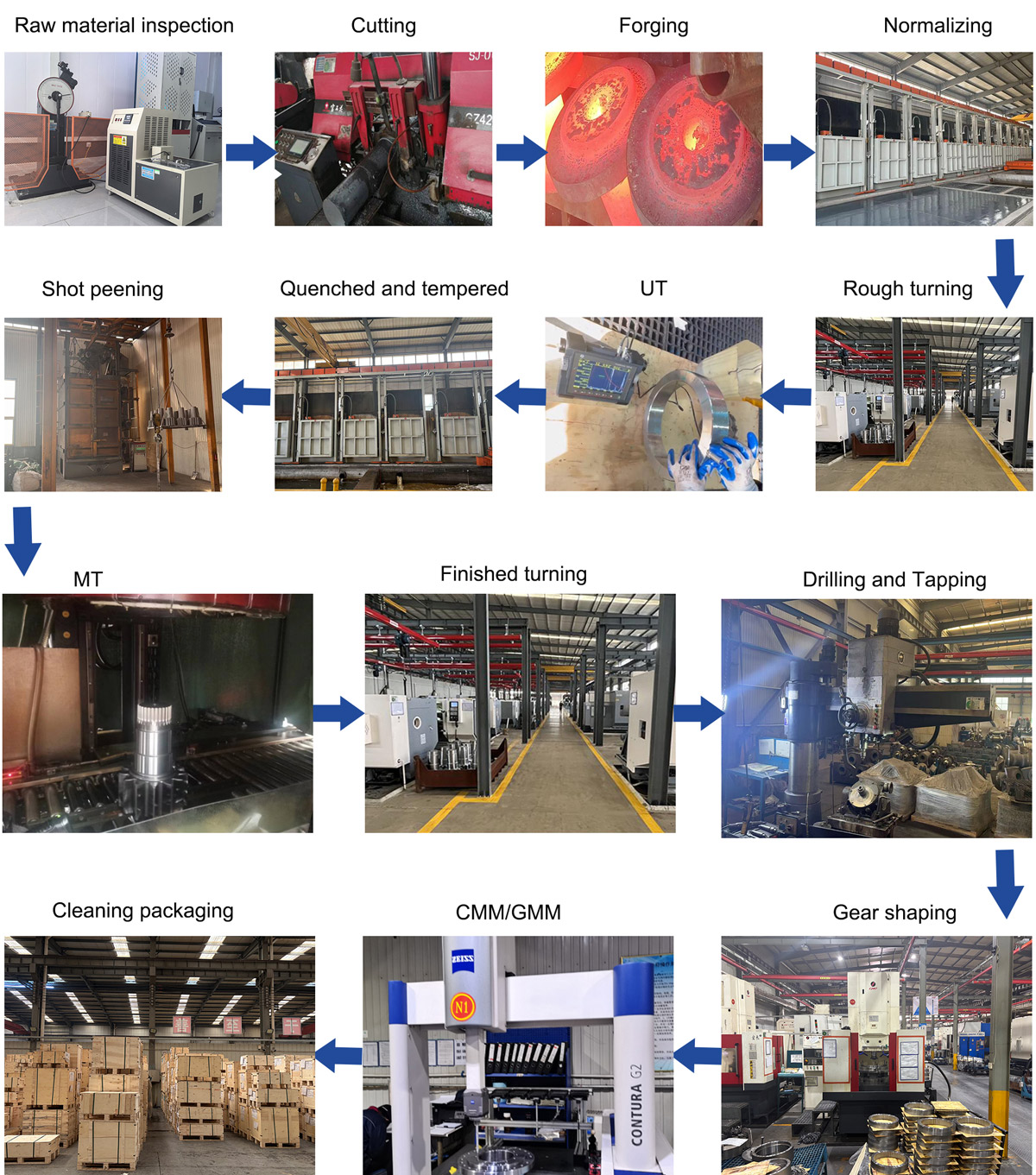

Production Process:

Raw material inspection→ Cutting→ Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → Shaping → CMM/GMM → Cleaning packaging

Our team will:

Clean, label, and take a appear to be at rust-proofing to all merchandise in the previous than shipment;

Perform a meticulous show off up inspection;

Finally pack the merchandise and hold them in our warehouse, making excessive fantastic readiness for dispatch.

Company Strength:

Over the previous 30 years of lively development, the enterprise has aggressively prolonged into each and every home and world markets. Its merchandise are considerably used in fields such as placing up machinery, wind electrical electrical energy generation, new electrical electricity vehicles, rail transit, petrochemicals, and mining machinery. The corporation has installed in-depth cooperation with world-renowned corporations in the United States, Canada, Germany, Italy, Belgium, Japan, and high-quality countries, with far-off places capital patron earnings accounting for elevated than 50%. It has in addition installed strategic partnerships with domestic predominant high-end tools producers such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. Among its products, the market share of planetary reducer core forgings and medium-to-large lifting hook assemblies ranks first in the home market.