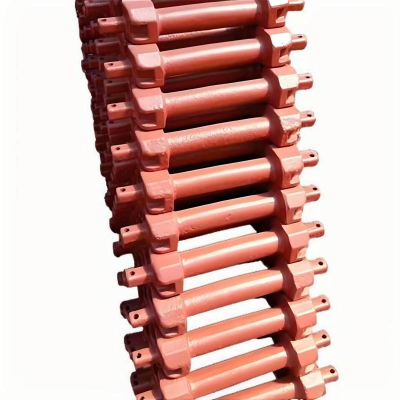

Mining Pin Rails Forging Parts

1.Material:42CrMo

2.Machining accuracy:

Excircle: ±0.01mm

3.Mold opening cycle:About 45days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Craft:Forging

Product Introduction:

As a critical guiding and transmission component in coal mining operations, the pin rail serves as the core interface enabling specialized meshing transmission between the scraper conveyor and shearer. Functioning as a dual-purpose component that combines the roles of "track and gear" in the automated operation system of fully mechanized mining faces, its performance directly impacts coal mining efficiency and the operational safety of the entire equipment fleet. Moreover, the service condition of the pin rail is closely tied to the stable and continuous operation of the shearer—any wear, deformation, or damage to the pin rail will lead to traction jams, vibration anomalies, or even sudden equipment downtime.

Product Advantages:

Boasting high transmission efficiency, the pin rail outperforms conventional transmission methods such as chain drive by a significant margin. This advantage effectively curtails energy loss and cuts down the shearer’s power consumption, contributing to more cost-effective and eco-friendly mining operations. In the harsh underground coal mine environment—characterized by high humidity, heavy dust, and constant friction against coal and rock—the pin rail’s superior wear resistance comes into full play. It minimizes the wear and tear caused by long-term meshing operations, substantially extending the component’s service life and reducing the frequency of replacements. This not only lowers maintenance costs but also reduces the need for frequent downtime for part swaps. Furthermore, the pin rail’s reliable operational performance prevents unexpected equipment failures that would otherwise halt production. It ensures the shearer maintains a steady running speed, enabling continuous and uninterrupted work on the mining face. In turn, this stability boosts the overall output and operational efficiency of the fully mechanized mining system.

Production Process:

Raw material inspection→Cutting→Forging→Normalizing→Rough turning→UT→Quenched and tempered→Shot peening→MT→Finished turning→Drilling and Tapping→CMM/GMM→Cleaning packaging

Packaging And Shipping:

Our dedicated operations team adheres to a rigorous, multi-step pre-shipment protocol to ensure every product leaves our facility in optimal condition, fully primed for safe and efficient dispatch:

First, all merchandise undergoes a comprehensive three-in-one preparation process tailored to its material and application characteristics. Each unit is subjected to precision cleaning using industrial-grade degreasers and high-pressure rinsing to eliminate machining residues, metal shavings, and surface contaminants; then affixed with durable, scannable labels that include critical traceability information such as model number, batch code, and production date; finally, targeted rust-proofing treatments—ranging from industrial-grade anti-rust oil coatings for ferrous components to corrosion-inhibiting sprays for alloy parts—are applied to shield against environmental damage during transit and storage. Next, our certified quality control specialists conduct a meticulous, item-by-item inspection against strict quality benchmarks. This verification covers surface finish integrity, labeling accuracy, the effectiveness of anti-corrosion treatments, and compliance with dimensional and performance specifications. Any product that fails to meet our stringent standards is immediately flagged for rework or replacement, with full documentation of corrective actions taken to ensure accountability. Finally, all qualified products are carefully packaged using industrial-grade protective materials customized to their size, weight, and fragility—such as shock-absorbent foam inserts for precision components, moisture-resistant wrapping for metal parts, and reinforced wooden crates for heavy-duty equipment. These securely packaged items are then systematically stored in our climate-controlled, well-organized warehouse, where real-time inventory tracking is maintained to guarantee rapid turnaround and on-demand dispatch as soon as shipping instructions are received.

Company Strength:

With three decades of steady, robust expansion, the company has successfully cemented its presence across both domestic and international markets, emerging as a trusted supplier of high-performance components for a diverse array of critical industries. Its product portfolio caters extensively to key sectors including construction machinery, wind power generation, new energy vehicles, rail transit, petrochemical processing, and mining equipment, each engineered to meet the rigorous operational demands of these specialized fields. On the global stage, the company has cultivated deep, long-standing partnerships with world-renowned enterprises spanning the United States, Canada, Germany, Italy, Belgium, Japan, and beyond—a testament to its adherence to international quality standards and reliable manufacturing capabilities. This global outreach is reflected in overseas sales revenue, which accounts for over 50% of its total annual turnover, highlighting its strong competitiveness in the international marketplace. Domestically, it has forged strategic alliances with leading high-end equipment manufacturers such as Zoomlion, XCMG, Sany, Lingong, CRRC, Nanjing Gear, and Zhuzhou Gear, fostering seamless supply chain synergy and joint innovation initiatives that drive industry progress. A standout achievement lies in its core product offerings: planetary reducer core forgings and medium-to-large lifting hook assemblies. Both product lines hold the top domestic market share in their respective categories, solidifying the company’s position as an industry leader in these high-value, technically demanding segments.