Transformer Oil Tank Shell: The core value of transformer oil tank shell and the empowerment of welding process

Transformer Oil Tank Shell: The core value of transformer oil tank shell and the empowerment of welding process

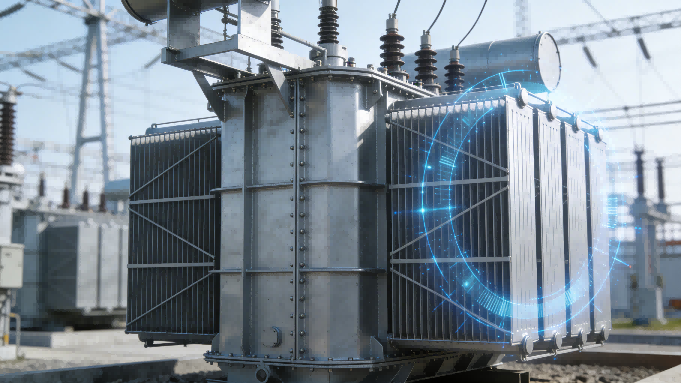

In core fields such as power transmission and industrial production, transformers, as key equipment for energy conversion and distribution, their stable operation is directly related to the reliability of the entire power system. The transformer oil tank shell, as the "protective barrier" and "structural skeleton" of the transformer, seems to be a simple metal shell, but in fact, it is the core component that ensures the long-term operation of the transformer. Many practitioners are puzzled: What is the core function of the transformer oil tank shell? Why is the welding process the key to determining its quality? Where is its compatibility with industrial core components such as slewing reducer reflected? This article will dissect the core value of the transformer oil tank shell for you from three dimensions: functional analysis, welding process, and industry application.

I. Transformer Oil Tank Shell: The triple core of "Protection + Heat Dissipation + Structure" of the transformer

The transformer oil tank shell is by no means an ordinary metal container, but a key component that integrates protection, heat dissipation and structural support. Its performance directly affects the service life and operational safety of the transformer.

Sealed protection, isolated from external invasion

The insulating oil filled inside the transformer is the core medium for ensuring insulation and heat dissipation. The outer shell of the transformer oil tank, through precise structural design and welding sealing, can effectively prevent moisture, dust and impurities in the air from entering the box, avoiding the deterioration of the insulating oil due to moisture and the rusting and short circuit of the internal coils. Especially in complex environments such as outdoors and industrial workshops, a high-quality oil tank shell can create a clean and stable operating environment for the core components inside the transformer, reducing the risk of failure.

Heat dissipation and conduction, balancing the working temperature

During the energy conversion process of a transformer, a large amount of heat is generated. If the heat accumulates, it will cause the insulating oil to age and the components to undergo thermal deformation, seriously affecting the operational efficiency. The transformer oil tank shell expands the heat dissipation area by optimizing the shell structure (such as adding heat sinks and corrugated oil tank design), quickly conducts the internal heat to the external environment, and achieves temperature balance in combination with the circulation flow of insulating oil to ensure the continuous and stable operation of the transformer under the rated load.

Structural support enhances overall rigidity

The internal components of a transformer, such as coils and cores, are heavy, and they are subject to external forces like vibration and shock during transportation, installation and operation. The transformer oil tank shell is reinforced through reasonable sheet metal forming and welding, providing stable installation support for internal components. At the same time, it enhances the overall structural rigidity of the transformer, resisting jolts and impacts during transportation and electromagnetic vibrations during operation, and preventing component displacement or damage.

Adapt core components to ensure system coordination

In industrial scenarios, transformers are often used in conjunction with transmission equipment such as slewing reducers (such as power systems in wind power and construction machinery). High-quality transformer oil tank shell, through precise size control and welding accuracy, can form a coordinated adaptation with the installation base and heat dissipation system of slewing reducer, avoiding installation difficulties or operational interference caused by size deviations, and ensuring the coordinated and efficient operation of the entire set of industrial equipment.

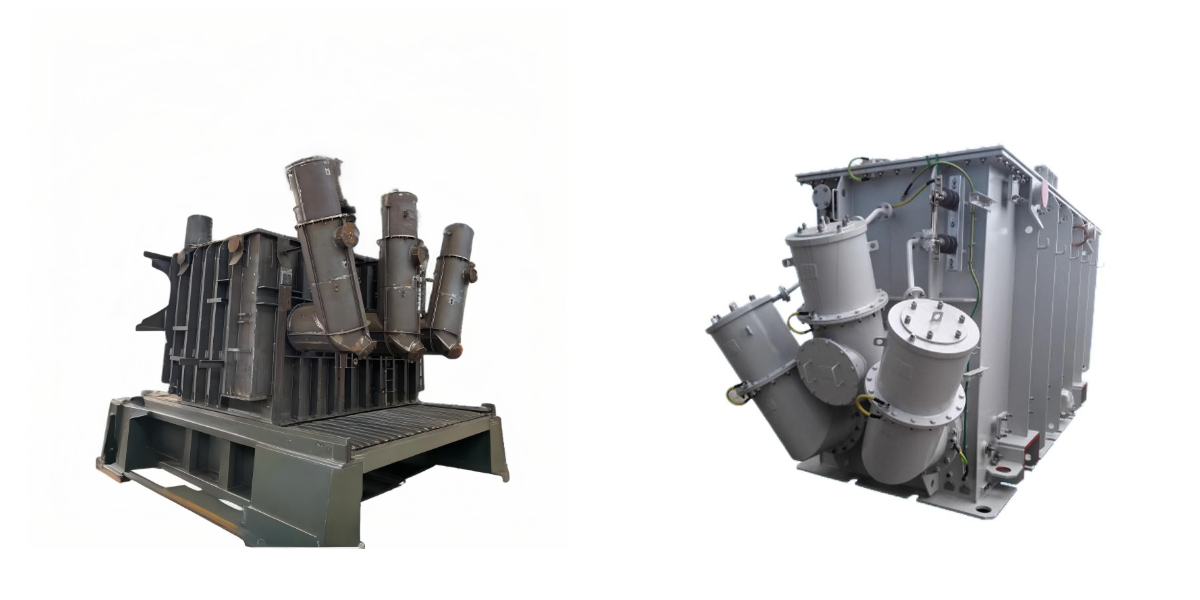

Ii. Welding Process: The "Core Technology" Determining the Quality of Transformer Oil Tank Shell

The performance advantages of the transformer oil tank shell cannot be separated from the in-depth empowerment of welding technology. As a key link in the shell forming and sealing, the welding quality directly affects the sealing performance, structural strength and service life of the fuel tank, and is the core indicator to distinguish high-end products from ordinary ones

The "key guarantee" of sealing performance

The sealing reliability of the transformer oil tank shell is entirely dependent on the precision of the welding process. If there are defects such as pores, slag inclusions, and incomplete penetration at the welding points, it will cause insulating oil leakage, which not only affects the heat dissipation effect but also may lead to equipment failure. High-quality manufacturers adopt precise welding techniques such as automatic submerged arc welding and argon arc welding, combined with non-destructive testing of weld seams (such as ultrasonic flaw detection), to ensure that the weld seams are smooth and dense, with sealing performance reaching IP65 or above protection levels, effectively preventing oil leakage and impurity intrusion.

The "reinforcing core" of structural strength

The casing of the transformer oil tank needs to withstand the pressure of the internal insulating oil, the impact of the external environment and the weight load of the internal components. Through reasonable welding processes (such as continuous welds and fillet weld reinforcement), the components of the shell can be closely connected, enhancing the overall structural strength and anti-deformation capacity. For instance, the application of robot welding technology can achieve uniform and consistent weld seams, avoid the unstable defects of manual welding, enable the fuel tank shell to withstand long-term vibration and load impact, and extend its service life.

"Process Support" adapted to complex working conditions

In special scenarios such as wind power, nuclear power, and construction machinery, transformers need to withstand extreme working conditions like high and low temperatures, high humidity, and corrosion. In response to these demands, the welding process will be combined with dedicated welding materials (such as weathering steel electrodes and stainless steel wires) and pretreatment processes (such as rust removal and preheating) to ensure a good metallurgical bond between the weld seam and the shell material, enhancing the overall corrosion resistance and resistance to high and low temperatures. Adapt the transformer oil tank shell to the harsh industrial environment where the slewing reducer is located.

Iii. Industry Applications of Transformer Oil Tank Shell: The "Core of Power Protection" Covering Multiple Fields

Transformer oil tank shell, with its reliable protection, heat dissipation and structural performance, is widely used in various power scenarios and has extremely strong compatibility with devices such as slewing reducer:

Wind power industry

In the wind turbine generator set, the transformer works in coordination with the slewing reducer (the slewing reducer controls the rotation of the nacelle, and the transformer is responsible for electrical energy conversion). The oil tank shell of wind power transformers needs to withstand harsh environments such as strong winds at high altitudes, low temperatures, and salt spray. Through precise welding and weather-resistant steel materials, it meets the requirements of anti-corrosion, anti-vibration, and reliable sealing, ensuring the long-term stable power generation of the wind power system.

The field of industrial manufacturing

In scenarios such as machine tools, construction machinery, and mining equipment, transformers provide stable power for the equipment, while slewing reducers are responsible for transmission control. The transformer oil tank shell, through compact design and high-strength welding, is adapted to the narrow installation space of the equipment, while resisting the high-frequency vibration during equipment operation, avoiding weld cracking or oil leakage caused by vibration, and ensuring the reliable coordination of power supply and transmission system.

Power transmission and distribution

The oil tank shells of transformers in substations and distribution rooms are designed with corrugated patterns and efficient welding to achieve large-capacity heat dissipation and sealed protection, adapting to different indoor and outdoor environments and ensuring stable power distribution to industrial production and residential life scenarios.

The field of new energy

The transformer and oil tank shells in photovoltaic power stations and energy storage power stations adopt lightweight design and precise welding technology. While enhancing the structural strength, the self-weight is reduced. Combined with the installation requirements of auxiliary equipment such as slewing reducer, the overall equipment layout is optimized to improve the energy conversion efficiency.

Iv. Key Points for Selection: Three Core Considerations for the Transformer Oil Tank Shell

Whether it is the selection of equipment manufacturers or the purchase of end users, when choosing high-quality transformer oil tank shell, the following three points need to be focused on:

Welding process and quality inspection: Give priority to products that adopt automatic welding technology (such as robot welding, submerged arc welding) and provide non-destructive testing reports of weld seams to ensure sealing performance and structural strength.

Material and working condition compatibility: Select appropriate materials (such as common carbon steel, weathering steel, stainless steel) based on the application scenarios, and match them with corresponding welding processes to ensure compatibility with high-temperature, corrosive, vibration and other working conditions.

Dimensional accuracy and compatibility: Confirm the dimensional tolerance of the oil tank shell and the positional accuracy of the installation interface to ensure the installation compatibility with the internal components of the transformer and the supporting equipment such as slewing reducer, and avoid assembly interference.

Summary

The transformer oil tank shell, as the "protective barrier" and "structural core" of the transformer, its sealing, heat dissipation and support performance directly determine the operational reliability of the transformer. The welding process, as the core enabling technology, enhances the sealing accuracy, structural strength and adaptability to working conditions, enabling the transformer oil tank shell to perfectly meet the demanding requirements in industrial scenarios and form coordinated operation with core equipment such as slewing reducer.

Under the background of power system upgrading and the development of industrial intelligence, choosing high-quality and exquisitely crafted transformer oil tank shells is the key to ensuring the long-term stable operation of equipment and reducing maintenance costs. If you need to further understand the welding process details of the transformer oil tank shell, customized solutions or adaptation cases with slewing reducer, please feel free to contact us at any time!