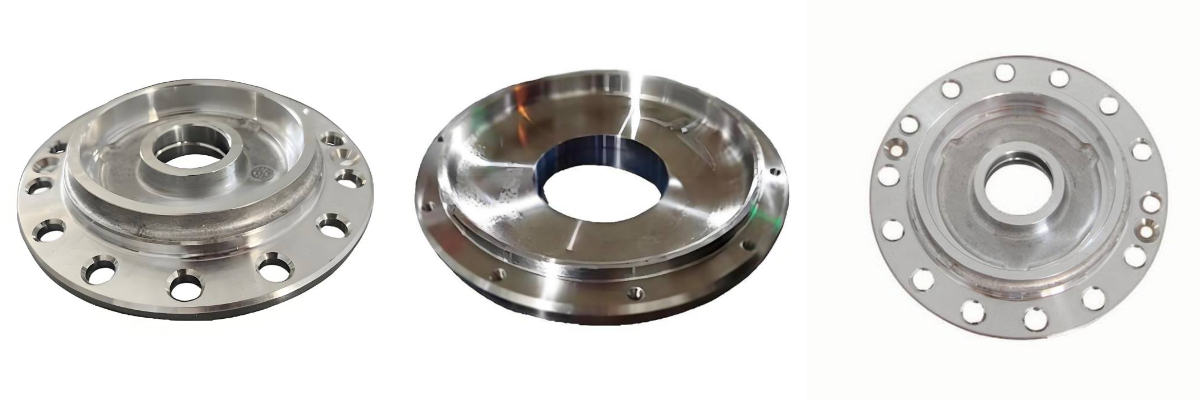

High Strength EV Motor Rotor Mounting Base

1.Material:42CrMo

2.Machining accuracy:

Excircle: ±0.01mm

3.Mold opening cycle:About 45days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Craft:Forging

Product Introduction:

The base is a core load-bearing aspect of the rotor in new electricity vehicle stress motors. It serves as every the set up foundation for eternal magnets and rotor cores, and a key structure for torque transmission. As the "framework" of the motor rotor, the exceptional of the rotor base straight away influences the dynamic performance, electrical energy consumption, and safety of new energy vehicles. Its diagram and manufacturing desire to balance strength, precision, and cost, making it an vital hyperlink in the localization of core factors for new electrical energy vehicles.

Product Advantages:

Although the rotor base is no longer a core thing right away involved in electromagnetic energy conversion, it has flip out to be a "fundamental guarantee" for the reliable operation of new electricity vehicle motors with the aid of its advantages such as "high-strength assist to make certain safety, lightweight format to embellish responsiveness, built-in sketch to store space, vibration and noise cut price to optimize experience, and sturdy local weather resistance to prolong issuer life". Its graph stage is besides prolong related to the motor's electricity density, efficiency, NVH performance, and automobile reliability, making it a key hyperlink in the enchancment of lightweight and pretty built-in motors for new electrical energy vehicles.

Production Process:

Raw material inspection→Cutting→Forging→Normalizing→Rough turning→UT→Quenched and tempered→Shot peening→MT→Finished turning→Drilling and Tapping→CMM/GMM→Cleaning packaging

Packaging And Shipping:

Our expert crew enforces strict first-rate manipulate for each and every and every order. Before shipment, all merchandise are certainly cleaned, truely labeled, and dealt with with rust-proof coating. A complete viewed inspection follows to assurance pinnacle cost quality. Finally, we cautiously bundle and preserve objects in our geared up warehouse for proper now dispatch readiness.

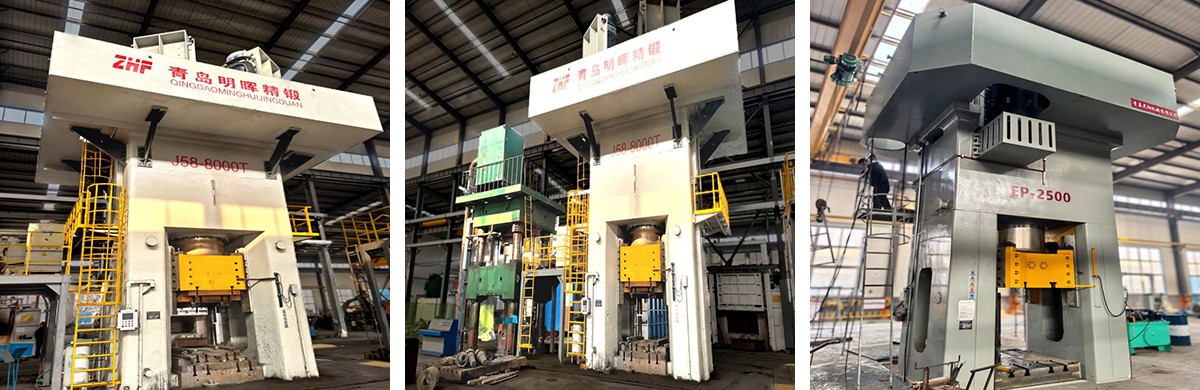

Company Strength:

The company is geared up with most advisable inspection and making an attempt out units such as imported spectrometers, nitrogen-hydrogen-oxygen analyzers, Zeiss metallographic microscopes, Zeiss CMMs, and M2M ultrasonic phased array flaw detectors. It has the whole common general overall performance to habits inspections from raw cloth composition, performance, dimensions, shape and characteristic tolerances to non-destructive testing.