What is a driven gear?

What is a driven gear?

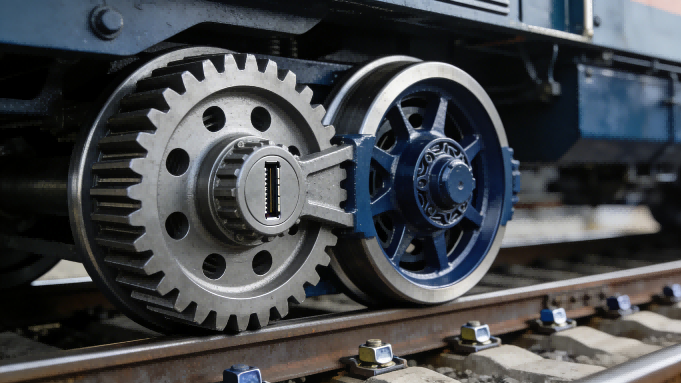

In the train rail parts system, gear transmission is the core link that ensures the power transmission, operational accuracy and safety stability of the train. The driven gear, as a key component of the gear transmission system, its performance directly affects the operational efficiency and reliability of the rail train. Many practitioners are puzzled: What exactly is driven gear? What role does it play in train rail parts? Why must the driven gear of high-end rail equipment rely on forging process for manufacturing? This article will comprehensively disassemble the core value of driven gear for you from four dimensions: definition analysis, core role, process empowerment, and industry application.

I. Basic Understanding of driven gear: The "Power Receiving Core" of the Track Transmission System

Driven gear, translated into Chinese as "driven gear", is a core component that works in conjunction with the "driving gear" in mechanical transmission. The driving gear receives the driving torque from the motor or power source and transmits the power to the driven gear through the meshing of the tooth surfaces, thereby driving the subsequent actuator to operate. In train rail parts, driven gear is widely used in key parts such as train bogies, traction drive systems, braking systems, etc. It is the "bridge" connecting the power source and the actuating components.

Unlike the driven gears in ordinary machinery, the driven gear in train rail parts needs to meet three special requirements: First, it has a stronger carrying capacity and needs to withstand the instantaneous large torque when the train starts and brakes; Second, it has higher precision, ensuring the smoothness of transmission when the train is running at high speed. Thirdly, it has better fatigue resistance and is suitable for the long-term and high-frequency operation requirements of rail equipment. The realization of these requirements cannot be achieved without the deep empowerment of the forging process.

Ii. The Core Role of driven gear in train rail parts: Ensuring the safe and efficient operation of trains

In the core system of the rail train, the role of driven gear runs through the entire process of power transmission, speed regulation and safe braking, and it is an indispensable key component in train rail parts:

Accurately convey the traction power

In the train traction drive system, the driven gear works in conjunction with the driving gear to convert the power of the traction motor into the rotational power of the wheel set, driving the train forward. The meshing accuracy of its tooth surfaces directly determines the power transmission efficiency. High-quality driven gear can reduce power loss and enhance the traction performance and endurance of the train (especially for new energy rail trains).

Adjust the operating speed and torque

The precise adjustment of train speed and torque can be achieved by changing the ratio of teeth between the driven gear and the driving gear. For example, on uphill sections, driven gear enhances torque by increasing the transmission ratio to help the train climb smoothly. On a straight track, energy consumption is reduced by optimizing the ratio of teeth to achieve high-speed and stable operation.

Ensure the reliability of the braking system

In the braking system of rail trains, driven gear is involved in the transmission and distribution of braking torque. Through the coordinated work with brake discs and brake pads, it achieves smooth deceleration or stopping of the train. Its structural strength and stability are directly related to the braking effect and serve as the "key defense line" to ensure the safety of train operation.

Buffer vibration and enhance operational smoothness

When the train is in operation, it will face vibration disturbances such as uneven tracks and wheel-rail contact impacts. driven gear, through optimizing the tooth profile design and high-precision processing, can effectively buffer vibrations, reduce noise, improve the smoothness of train operation and passenger comfort, and at the same time reduce the wear of other train rail parts.

Iii. Process Empowerment: Adapting driven gear to the demanding requirements of train rail parts

The working environment of train rail parts is extremely complex. The driven gear needs to withstand multiple tests such as high-frequency vibration, instantaneous heavy load, and temperature fluctuation. Ordinary casting or stamping processes are difficult to meet its performance requirements. The forging process, through high-temperature and high-pressure forging of metal billets, can fundamentally enhance the comprehensive performance of driven gear and become the preferred process for high-end train rail parts:

The strength and load-bearing capacity are doubled

The forging process refines the internal grains and compacts the structure of the metal billet, completely eliminating the defects such as pores and sand holes that are prone to occur in castings. The forged driven gear has a tensile strength of 800-1200 mpa and a yield strength that is over 50% higher than that of castings. It can easily withstand the instantaneous large torque impact during train start-up and braking, avoiding gear breakage, tooth surface spalling and other faults.

Higher precision and smoother meshing

Train rail parts have extremely high requirements for the tooth surface accuracy and pitch error of driven gear. Even the slightest deviation may cause transmission jamming and increased noise. The precise forging process can achieve near-net-shape forming of driven gear, with the tooth surface roughness controlled below Ra0.8μm and dimensional tolerances accurate to the micrometer level. Only a small amount of finishing is required subsequently to meet the assembly requirements, ensuring perfect meshing with the driving gear and enhancing the smoothness of transmission.

Strong fatigue resistance, extending service life

The operation cycle of the rail train lasts for 15 to 20 years, and the driven gear needs to withstand high-frequency cyclic loads for a long time. The driven gear treated by the forging process features a continuous distribution of metal fibers along the tooth profile direction. Its fatigue resistance far exceeds that of products made by ordinary processes. It can maintain structural stability during long-term use, reduce the frequency of maintenance caused by fatigue damage, and lower the maintenance costs for track operators.

Adapt to extreme environments and enhance reliability

Whether in high-temperature or extremely cold climatic conditions or in damp and dusty tunnel environments, the driven gear crafted by forging technology can maintain stable performance. Its dense metal structure can resist corrosion and oxidation. Combined with subsequent heat treatment processes (such as carburizing and quenching), the hardness and wear resistance of the tooth surface can be further enhanced, ensuring the long-term reliable operation of driven gear in complex environments.

Iv. Industry Applications and Selection Points of driven gear: Focus on the train rail parts scenario

1. Typical application scenarios

The application of driven gear in train rail parts covers the entire range of rail equipment:

High-speed EMU: The driven gear in the traction drive system needs to meet the requirements of high speed, low noise and high precision. The forging process can ensure stable transmission at a speed of 350km/h.

Urban rail transit (subways, light rails) : The driven gear in the braking system needs to frequently bear braking torque. The high fatigue resistance of forgings can reduce the failure rate.

Freight trains: The driven gear of heavy-duty freight trains needs to withstand extremely large torques. The high-strength characteristics of the forging process can ensure the reliability of power transmission.

Driven gear for rail engineering vehicles, such as rail grinding vehicles and track-laying machines, needs to be adapted to harsh construction environments. The corrosion resistance and impact resistance of forged parts make it the preferred choice.

2. Key points for selection

For train rail parts manufacturers and track operators, there are three key points to focus on when choosing high-quality driven gear:

Process priority: driven gear manufactured by forging process must be selected to avoid performance deficiencies caused by process defects and ensure compatibility with the harsh working conditions of rail equipment.

Material matching: Select appropriate materials based on the application scenarios. For instance, high-strength alloy steel should be chosen for heavy-load scenarios, and stainless steel or anti-corrosion coated forgings for corrosive environments.

Inspection standards: Confirm that driven gear has passed strict quality inspections, including tooth profile accuracy inspection, non-destructive testing, fatigue life testing, etc., to ensure compliance with ISO, EN and other rail industry standards.

Summary

Driven gear, as the core transmission component in train rail parts, is the key to ensuring the power transmission, speed regulation and safe operation of rail trains. The forging process, by enhancing the strength, precision and fatigue resistance of driven gear, perfectly meets the demanding requirements of rail equipment and becomes the standard process for high-end train rail parts.

Whether it is the product research and development of rail equipment manufacturers or the maintenance and upgrading of rail operators, only by recognizing the core values of driven gear and identifying high-quality products with forging processes can the safe, efficient and long-term operation of rail trains be ensured. If you need to know more about driven gear 's customized solutions or technical details of forging process, please feel free to contact us at any time!