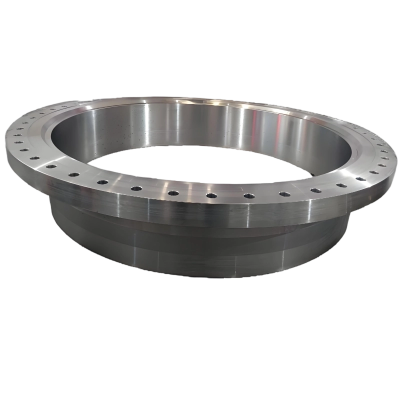

Wind Power Planetary Carrier

1.Material:42CrMo/40Cr

2.Machining accuracy:

Excircle: ±0.01mm

Tooth accuracy: Grade 5

3.Mold opening cycle:About 45 days

4.Advantages:

Full-process inspection

Full-process processing capability

Full-range products

5.Customization: Provide custom-engineered solutions according to provided technical drawings.

6.Weight/Size:Execute custom orders with 100% drawing compliance

7.Craft:Forging

Product Introduction:

The planetary carrier in a planetary gearbox is one of the core factors of the planetary tools transmission system. It derives its identify from the shape that resembles planets orbiting a star. Comprising a physique body, bearing mounting positions, and gear connection parts, it is typically crafted from high-strength alloy steel with the resource of forging and machining processes. Its structural shape balances strength, rigidity, and light-weight necessities to make advantageous everyday operation below challenging working conditions.

Product Advantages:

The planetary carrier is a core component of the planetary gear transmission system. It aspects a compact structure, excessive neighborhood efficiency, robust load-bearing capacity, handy transmission, excessive transmission efficiency, bendy installation, handy maintenance, sturdy environmental adaptability, big compatibility with working conditions, and a massive vary of utility scenarios. It performs an irreplaceable role, in the main in fields such as enchancment machinery, automotive, and aerospace.

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → Shaping → CMM/GMM → Cleaning packaging

Packaging and Shipping

Our team will undertake a comprehensive series of pre-shipment procedures to ensure the merchandise meets the highest standards before dispatch:

First, we will thoroughly clean each item to remove any dust, debris, or residues accumulated during production or storage, ensuring a pristine condition. Following the cleaning process, we will affix clear, accurate labels to every product, including essential details such as product codes, specifications, batch numbers, and handling instructions, to facilitate smooth tracking and identification throughout the supply chain. Concurrently, we will conduct a detailed examination of the rust-proofing treatments applied to the merchandise—whether it be protective coatings, anti-corrosive films, or specialized lubricants—to verify their integrity and effectiveness, ensuring long-term protection against environmental factors during transit and storage.

Next, a meticulous appearance inspection will be carried out. Our inspectors will scrutinize each product for any signs of damage, scratches, dents, or irregularities in surface finish, using both visual checks and precision tools to guarantee that every item adheres to the defined quality criteria.

Finally, once all inspections and preparations are completed, we will carefully pack the merchandise using appropriate materials—such as shock-absorbent padding, moisture-resistant wraps, and sturdy cartons—to prevent damage during transportation. These packed items will then be stored in our well-organized warehouse, where they will be kept in optimal conditions (controlled temperature, humidity, and secure shelving) to maintain their quality. We will also implement a strict inventory management system to ensure each shipment is readily accessible and prepared for timely dispatch, minimizing any delays in fulfilling orders.

Company Strength:

Over the previous 30 years of active development, the company has aggressively extended into each home and world markets. Its merchandise are considerably used in fields such as establishing machinery, wind electrical strength generation, new electrical energy vehicles, rail transit, petrochemicals, and mining machinery. The enterprise has established in-depth cooperation with world-renowned companies in the United States, Canada, Germany, Italy, Belgium, Japan, and wonderful countries, with remote places capital customer income accounting for greater than 50%. It has in addition frequent strategic partnerships with home predominant high-end tools producers such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. Among its products, the market share of planetary reducer core forgings and medium-to-large lifting hook assemblies ranks first in the home market.