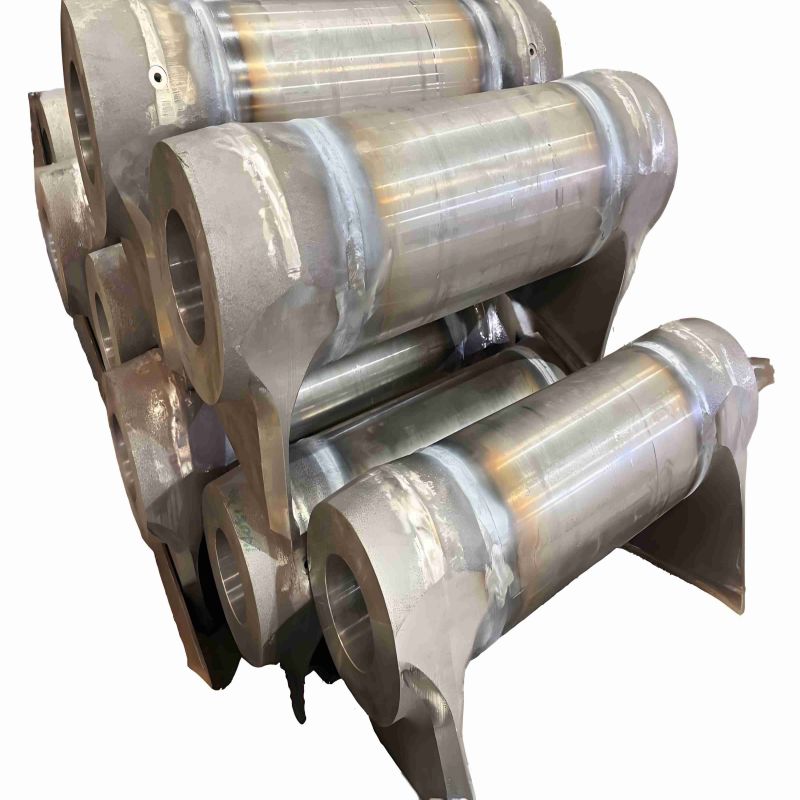

Support Flange In Boom

1.Material:35#(ASTM:1035 EN:C35E4 DIN:CK35),20MnMo,20#

2.Machining accuracy:±0.5mm

3.Customization: We design and manufacture tailor-made products to your exact technical requirements.

4.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

5.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

6.Craft:Forging

7.Size:Execute custom orders with complete compliance to the drawings provided.

Product Introduction:

The middle support assembly of the excavator's boom is a key structural component of the excavator's working device (boom). Its main function is to enhance the structural stability of the boom, disperse the load stress during operation, and provide connection fulcrums for related components, ensuring the reliable operation of the boom in high-intensity operations (such as excavating and lifting heavy objects). The middle support assembly is usually composed of a support base, shaft sleeve, connecting pin and other components made of forged steel or high-strength alloy steel. Some designs also include reinforcing ribs or bushings to reduce wear and improve assembly accuracy.

Product Advantages:

As a key forged component, the design and performance advantages of the middle support assembly of the excavator boom directly affect the operating efficiency, safety and service life of the excavator. The middle support assembly adopts forging technology to ensure the dimensional accuracy and uniform mechanical properties of the components, which can accurately disperse the stress concentration in the middle section of the boom and reduce the risk of local wear or damage. As the "support hub" in the middle section of the boom, its structural design (such as the support base with reinforcing ribs and high-precision shaft sleeves) can enhance the overall rigidity of the boom, reduce shaking or deformation during operation, ensure more precise movements of the bucket and stick, and improve excavation efficiency.

Production Process:

Forgings + Pipe Fittings Assembly → Welding → Non-Destructive Testing → Cleaning & Packaging → Shipment

Packaging and Shipping

Our team will: Clean, label, and take a exhibit up at rust-proofing to all merchandise in the preceding than shipment; Perform a meticulous showcase off up inspection Finally pack the merchandise and keep them in our warehouse, making fantastically actual readiness for dispatch.

Company Strength:

Over the previous 30 years of vigorous development, the business enterprise has aggressively prolonged into each and every and every and each and every and every home and world markets. Its merchandise are substantially used in fields such as inserting up machinery, wind electrical electrical electricity generation, new electrical electrical energy vehicles, rail transit, petrochemicals, and mining machinery. The organisation organization has set up in-depth cooperation with world-renowned corporations in the United States, Canada, Germany, Italy, Belgium, Japan, and outstanding countries, with some distance away areas capital buyer income accounting for massive than 50%. It has in addition everyday strategic partnerships with home predominant high-end tools producers such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. Among its products, the market share of planetary reducer core forgings and medium-to-large lifting hook assemblies ranks first in the home market.