New energy vehicle forgings: The core code of lightweight and high performance, determining range, safety and durability!

New energy vehicle forgings: The core code of lightweight and high performance, determining range, safety and durability!

In the race of new energy vehicles that pursue longer driving range, higher safety and better experience, forgings, as the "performance cornerstone" of core load-bearing components, have become the top choice in key areas such as electric drive systems, chassis suspension and battery safety, thanks to their unique advantages of lightweight, high strength and high precision. Many car manufacturers' purchasers and parts suppliers are puzzled: Which core components of new energy vehicles are forgings? Why can high-quality forgings solve the contradiction between "weight reduction and toughness"? How to select forging products suitable for the working conditions of new energy vehicles? This article will comprehensively disassemble the core value of new energy vehicle forgings from three dimensions: application scenarios, process advantages, and selection guidelines.

I. New Energy Vehicle Forgings: "Key Load-bearing Components" Distributed in Core Systems

Every acceleration, steering and braking of new energy vehicles cannot do without the stable support of forgings. These precisely forged components, which run through various core systems, are the "backbone" that strikes a balance between battery life and safety:

The core of the electric drive system: motor shaft, reducer gears, and half shaft forgings

The motor shaft is the "power transmission shaft" of the electric drive system, which needs to withstand a high-speed centrifugal force of 15,000 revolutions per minute. It is manufactured by a cold forging + nitriding composite process, with a cylindricity error controlled within ±0.003mm, a surface hardness of over 1300MPa, a weight reduction of 15% compared to traditional processed parts, and an 8% increase in transmission efficiency. The gears of the reducer are formed through cold precision forging and tooth surface grinding processes, with the tooth surface roughness as low as Ra≤0.4μm. The transmission noise is reduced by 15-20dB, perfectly meeting the low-noise requirements of new energy vehicles. The half shaft forgings are made of high-strength alloy steel through die forging, with a tensile strength exceeding 1000MPa, ensuring the stable transmission of power from the reducer to the wheels and coping with high-frequency alternating loads.

The key components of the chassis suspension: steering knuckles, control arms, and subframe forgings

The steering knuckle is the "core hub" of vehicle steering. It is made of aluminum alloy through die forging, with a density of over 99.9%. After T6 heat treatment, its tensile strength reaches 380MPa, reducing the weight by 30% compared to traditional stamping parts while enhancing steering accuracy. The control arm forgings are formed through integrated die forging, reducing the number of welding points by over 80%. The yield strength is ≥500MPa, and the impact toughness reaches 85J/cm², effectively absorbing the impact of the road surface. The subframe adopts semi-solid forming + T6 heat treatment process, which not only significantly reduces the weight but also enhances the rigidity of the chassis and improves the vehicle's handling stability.

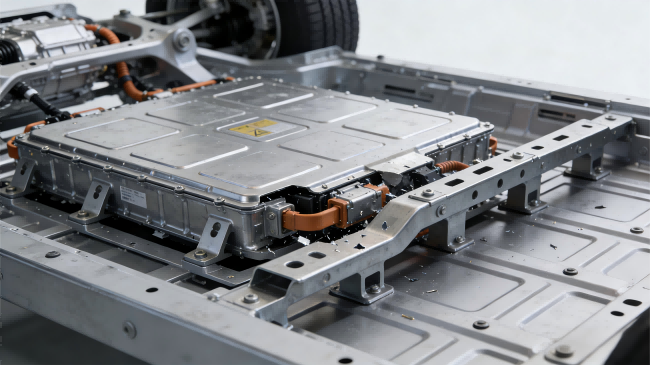

The core of battery safety: battery pack shell, bracket forgings

The battery pack is the "energy heart" of new energy vehicles. Its shell is made of aluminum alloy through an integral die forging process, reducing its weight by more than 30% compared to traditional welded structures and enhancing its impact resistance by 50%. It can effectively protect the battery module from damage in collision accidents. The bracket forgings are formed through precision die forging to achieve an integrated structure, with dimensional accuracy reaching IT6 grade, ensuring the stable installation of the battery pack. At the same time, they have excellent heat dissipation and conduction performance, avoiding local overheating and affecting the battery life.

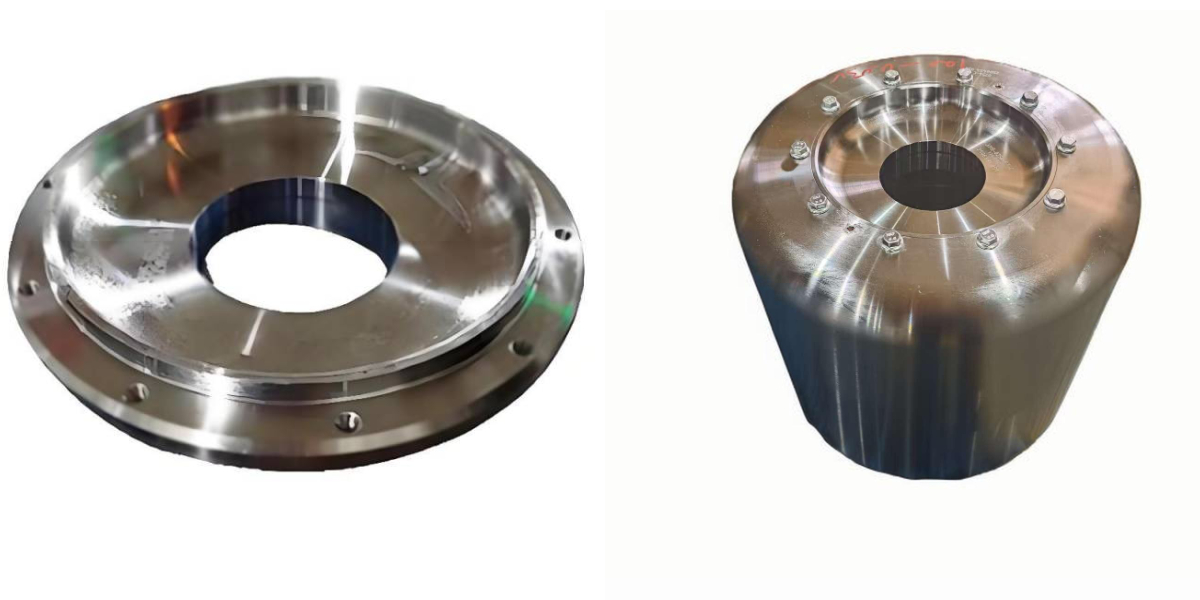

Key components for braking and connection: brake pistons, universal joints, pin shaft forgings

The brake piston needs to withstand high pressure and temperature shock. It is made by forging process, which has strong pressure resistance, corrosion resistance and wear resistance, ensuring that the braking system responds sensitively and reliably. The universal joint forging ensures a dense internal structure through annular forging, enabling stable power transmission at different angles and adapting to the complex layout of the chassis. The pin shaft forging serves as the connection hub for various components, with dimensional tolerances controlled within ±0.03mm. It features high assembly accuracy and strong connection stability, effectively reducing vibration and noise during operation.

Ii. Forging Process: The "Performance Upgrade Code" for New Energy Vehicle Forgings

The ultimate pursuit of lightweight and high safety in new energy vehicles has made forging technology the preferred manufacturing solution for core components. Forgings, with their four unique advantages, perfectly meet the working conditions of new energy vehicles:

Balancing lightweight and high strength to enhance battery life

Through topological optimization design and material substitution, forgings achieve ultimate weight reduction while ensuring strength. Forged from lightweight alloys such as aluminum alloy and magnesium alloy, the strength of magnesium alloy forgings is over 30% higher than that of traditional materials. Combined with structural optimizations such as hollow and ribbed parts, the vehicle weight can be reduced by 20%, directly extending the driving range. For instance, the integrated chassis forgings are 30% lighter than the traditional stamping and welding structures, significantly reducing energy consumption.

The organization is dense and highly precise, ensuring stable operation

The forging process, through high-temperature and high-pressure forging, makes the metal grains fine and uniform, completely eliminating defects such as pores and sand holes. Precision die forging technology can achieve dimensional accuracy of IT6 grade and surface roughness of Ra≤0.4μm, as well as high-precision fit of motor shafts, gears and other components. It can reduce friction loss during operation, improve transmission efficiency, and at the same time lower the failure rate, extending the service life of core components to more than 10 years.

Integrated molding enhances structural rigidity

By using large hydraulic presses with a capacity of over 6,000 tons to achieve integrated die forging, multiple scattered components are consolidated into a single forging, reducing a large number of welding points and significantly enhancing the structural rigidity and fatigue resistance. For instance, the integrated subframe forgings not only simplify the assembly process but also enhance the overall load-bearing capacity of the chassis, improving the vehicle's driving stability and handling.

Low-noise feature optimizes the driving and riding experience

In response to the core demand of "low noise" for new energy vehicles, forgings undergo processes such as precision machining of tooth surfaces and surface polishing to reduce vibration and noise during transmission. After the gear forgings undergo cold precision forging and grinding treatment, the transmission noise is significantly reduced. Combined with high-precision assembly, the vehicle operates more quietly and smoothly, enhancing the driving and riding comfort.

Iii. Guide to Selecting Forgings for New Energy Vehicles: 3 Key Points to Avoid Procurement Misunderstandings

For automakers and parts suppliers, choosing the right forgings is the key to ensuring product quality and market competitiveness. When purchasing, the following three points should be given particular attention:

Verify the process and testing qualifications

Give priority to suppliers that adopt composite processes such as cold forging and hot precision forging, and require them to provide complete inspection reports, including material test reports and non-destructive testing reports (ultrasonic flaw detection, magnetic particle flaw detection), to ensure that there are no cracks, inclusions or other defects inside the forgings, and the flaw detection pass rate is over 99.5%. At the same time, confirm that the supplier has industry certifications such as IATF16949, advanced production equipment, and can meet the requirements of precision forging.

Select materials and processes to match the working conditions

Select the type based on the application of the components: For high-speed rotating components of the electric drive system, give priority to cold-forged and nitrided alloy steel forgings. Lightweight components of the chassis are made of aluminum alloy or magnesium alloy die forgings. For the components related to battery packs, select integrated forgings that are impact-resistant and corrosion-resistant. For vehicles used in coastal areas, attention should be paid to the anti-corrosion treatment of the forgings to ensure that they can withstand salt spray corrosion for more than 500 hours.

Pay attention to the manufacturer's production capacity and cases

Give priority to suppliers with a complete industrial chain (smelting - forging - heat treatment - fine processing), which can ensure material consistency and process stability. Pay close attention to whether the manufacturer has cooperation cases with well-known car companies, whether the products have been verified under actual working conditions, and at the same time understand its customization capabilities and response cycle to ensure that it can meet the needs of vehicle model research and development and mass production.

Iv. Industry Trends: New energy vehicles drive forgings towards high-end iteration

With the continuous increase in the penetration rate of new energy vehicles, the market size of new energy vehicle forgings in China is expected to exceed 80 billion yuan in 2025, among which lightweight forgings account for more than 35%. The industry is upgrading in three major directions: First, precision. Digital simulation technology optimizes processes, and dimensional accuracy is moving towards the micrometer level. Second, the popularization of intelligent and automated forging equipment and real-time monitoring systems has significantly enhanced the consistency of product performance. The third is greening. By optimizing the process to reduce energy consumption and emissions, "green forging" can be achieved. At present, the import substitution rate of domestic forgings has exceeded 50% for the first time. The performance of some products has reached the international advanced level, making them a cost-effective choice for automakers.

Summary

Forgings are the core support for new energy vehicles to achieve lightweight, high performance and high safety. From the efficient transmission of the electric drive system to the safety protection of the battery pack, from the stable handling of the chassis to the reliable response of the braking system, every high-quality forging is empowering the quality upgrade of new energy vehicles. In the current era of rapid industry development, choosing high-quality forgings that are suitable for working conditions has become a key for automakers to enhance their core competitiveness.

If you need to know more about the customized solutions for new energy vehicle forgings, the performance comparison of forgings made of different materials, or obtain the technical parameter comparison table of core forgings, please feel free to contact us at any time! We will provide you with high-quality forging products that meet industry standards and professional technical support.

- Previous : Excavator forgings: The "hard core bones" for heavy-duty operations, the core components that determine the durability and efficiency of excavators!

- Next : New energy vehicle chassis vs. traditional fuel vehicle chassis: Forgings are the core of the gap, with dual breakthroughs in lightweighting and safety!