New energy vehicle chassis vs. traditional fuel vehicle chassis: Forgings are the core of the gap, with dual breakthroughs in lightweighting and safety!

New energy vehicle chassis vs. traditional fuel vehicle chassis: Forgings are the core of the gap, with dual breakthroughs in lightweighting and safety!

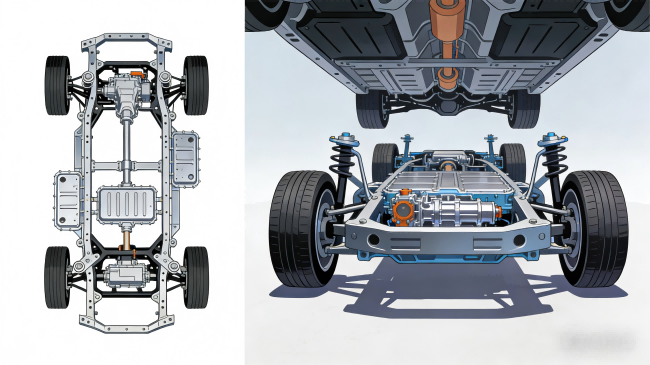

When new energy vehicles have become the mainstream of the industry, the competition for the chassis, as the "cornerstone of the vehicle", has long been extremely fierce. The core gap between the new energy vehicle chassis (Electric Car Base) and the traditional fuel vehicle chassis (ICE) is not only in the iteration of the power system, but also hidden in the application upgrade of the key component - forgings. The chassis of traditional fuel vehicles rely on stamped and welded parts to barely meet the demands, while new energy vehicles, in order to achieve longer driving range, higher safety and better handling, have pushed forgings to the core position. Why can forgings be the "decisive factor" for chassis upgrades? How big is the gap between the two in terms of structural design and performance? This article dissects the underlying logic of chassis competition from three major dimensions: core differences, application of forgings, and selection logic.

I. Core Differences: New energy vehicle chassis vs. traditional fuel vehicle chassis, forgings rewrite the competition rules

The chassis of traditional fuel vehicles is arranged around the engine and transmission, with scattered components and numerous welding points. The core load-bearing parts are mostly made of a combination of stamped and cast parts. Although it can meet the daily commuting needs, it has inherent shortcomings in terms of lightweight and torsional resistance. The new energy vehicle chassis (especially the pure electric dedicated platform) takes "integration, lightweight and high rigidity" as its core. Forgings, with their advantages of high strength, high precision and integration, have become the key to solving the pain points of the chassis. The core differences between the two are obvious:

Comparison Dimension | Internal Combustion Engine (ICE) Vehicle Chassis | New Energy Vehicle Chassis | Core Role of Forgings |

Structural Design | Decentralized layout, relying on multi-component welding | Integrated one-piece design (e.g., integration of battery pack and chassis) | One-piece forgings reduce welding points, enhancing structural rigidity by over 30% |

Core Materials | Mainly ordinary steel stamped parts + castings | High-strength alloy steel forgings + aluminum alloy forgings | Lightweight forgings achieve a 20%-30% reduction in chassis weight, extending driving range |

Mechanical Performance | Tensile strength generally below 800MPa, weak torsional resistance | Tensile strength of core forgings reaching 1000-1500MPa | Withstand battery weight increase and high-frequency acceleration impacts, reducing fracture risks |

Safety Protection | Predominantly passive protection, prone to deformation during collisions | Active protection design, requiring rigid support for the battery pack | Forged casings/supports resist collision impacts, safeguarding battery safety |

Durability | Welded joints are prone to fatigue, service life of approximately 8 years | Integrated structure, fatigue life increased by 50% | Forgings exhibit excellent fatigue resistance, suitable for the long lifecycle of new energy vehicles |

Ii. Application of Forgings in Two Types of Chassis: From "Barely Fitting" to "Tailor-made"

1. Traditional fuel vehicle chassis: Forgings are only used as "supplementary components"

The core load-bearing components of traditional fuel vehicle chassis are mainly stamping parts and castings. Only a small number of forgings are applied to key nodes such as drive shafts, half shafts, and steering knuckles, and most of them adopt ordinary forging processes. The materials are mainly 45# steel, and their performance only meets the basic requirements. For instance, the steering knuckles of fuel vehicles are mostly cast and partially forged, with insufficient impact toughness, and are prone to deformation in complex road conditions. The precision of the drive shaft forgings is relatively low, with a transmission efficiency loss of about 10%, and they are also heavy, increasing fuel consumption.

Essentially, the demand for forgings in traditional fuel vehicle chassis remains at the "usable" level, failing to fully leverage the strength and lightweight advantages of forgings. This is closely related to the power characteristics and design concepts of fuel vehicles - the noise and vibration of the engine can mask the performance shortcomings of the chassis components, and there is no need to optimize the weight for range anxiety.

2. New energy Vehicle Chassis: Forgings become the "core skeleton"

The three major characteristics of new energy vehicles - "increased battery weight, high-frequency acceleration, and low noise" - have forced a comprehensive upgrade of the chassis. Forgings have been upgraded from "supplementary components" to "core skeletons", covering three key scenarios:

Electric drive system connection: motor shaft, reducer gear forgings

The motor speed of new energy vehicles can reach 15,000 revolutions per minute, far exceeding that of fuel vehicle engines. Traditional cast gears cannot withstand the high-speed centrifugal force. The motor shaft forgings are processed by cold precision forging and nitriding, with a cylindricity error within ±0.005mm, a surface hardness of 1200MPa, and an 8% increase in transmission efficiency. The gears of the reducer are processed through cold forging and tooth surface grinding, with a tooth surface roughness Ra≤0.4μm, which solves the problems of high noise and rapid wear of traditional gears and meets the low-noise requirements of new energy vehicles.

Chassis load-bearing core: integrated subframe, control arm forgings

The battery pack adds 300 to 500 kilograms to the chassis, and the traditional stamped subframe is prone to deformation. New energy vehicles adopt integrated subframe forgings, which are formed by die forging with a 6,000-ton hydraulic press, integrating multiple scattered components into one. The torsional stiffness is increased by 50%, while the weight is reduced by 25%. The control arm forging is made of aluminum alloy die forging. After T6 heat treatment, its tensile strength reaches 380MPa, which is 40% lighter than traditional stamping parts. Moreover, it can absorb road impact and improve the smoothness of control.

Battery safety protection: Battery pack shell, bracket forgings

The battery pack is the "energy heart" of new energy vehicles, and its protection relies on the rigidity of the chassis. The battery pack shell is made of an integral forged aluminum alloy, with a density of over 99.9%. Its impact resistance is 60% higher than that of traditional welded shells, and it can effectively disperse the impact force during a collision. The bracket forgings achieve complex structure integration through precision die forging, with dimensional accuracy reaching IT6 grade, ensuring the stable installation of the battery pack. At the same time, it has excellent heat dissipation performance to prevent local overheating.

In addition, the half shafts, universal joints, brake pistons and other components of the new energy vehicle chassis all adopt high-end forgings, forming a "full-scenario forging coverage", fundamentally solving the three major pain points of traditional chassis: weight, rigidity and safety.

Iii. Chassis Upgrade Trend: Forgings drive the development of new energy vehicle chassis towards "perfection"

As new energy vehicles upgrade towards larger sizes, intelligence and higher performance, the demand for forgings in chassis is also evolving. Three major trends are becoming increasingly evident:

Higher degree of integration: From "multi-component combination" to "integrated forgings"

In the future, the chassis of new energy vehicles will adopt "chassis assembly forgings", such as integrating the front cabin bracket, battery pack frame and rear suspension base into a single integrated forging. Through 3D forging simulation technology to optimize the structure, the welding points will be reduced by over 90%, the torsional stiffness will be increased by 40%, and the weight will be further reduced at the same time.

Lightweight material upgrade: Magnesium alloy forgings are gradually becoming popular

Aluminum alloy forgings have become mainstream, while magnesium alloy forgings, with the advantage of "strength close to that of steel and weight only 1/4 of that of steel", have begun to be applied in high-end new energy vehicle models. Magnesium alloy control arm forgings are 15% lighter than aluminum alloy ones and have better fatigue resistance. They are expected to become standard equipment for mid-to-high-end models in the next 3 to 5 years.

Intelligent forging: Digital technology enhances performance consistency

The precision requirements for chassis components of new energy vehicles reach the micrometer level, which are difficult to meet by traditional forging processes. By simulating the forging process through digital twin technology and adjusting the temperature and pressure parameters in real time, the dimensional tolerance of the forgings can be controlled within ±0.02mm, and the performance fluctuation range can be reduced to less than 5%, ensuring the uniform quality of each batch of forgings.

Iv. Procurement Selection Guide: How to Choose New Energy Vehicle Chassis Forgings?

For automakers and parts suppliers, choosing the right forgings is the key to chassis upgrades. Three key points need to be focused on:

Process and Qualifications: Priority given to "composite forging + authoritative certification"

Core components (such as motor shafts and integrated subframes) should adopt a combined process of cold forging and heat treatment. Suppliers are required to provide ultrasonic flaw detection (UT) and magnetic particle flaw detection (MT) reports, with a flaw detection pass rate of over 99.5%. At the same time, it is confirmed that it has IATF16949 automotive industry certification and has cooperation cases with leading automakers.

Material matching: Select the right forging material according to the scene

For high-speed transmission components (motor shafts, gears), high-strength alloy steel forgings (such as 42CrMo, 35CrMo) are selected. For lightweight components (control arms, subframes), 6061/7075 aluminum alloy forgings are selected. For ultimate lightweight requirements, choose AZ31B magnesium alloy forgings. The protective components of the battery pack should be made of stainless steel forgings with strong corrosion resistance.

Customization capability: Adapt to the specific platform requirements

New energy vehicles mostly adopt dedicated chassis platforms, which require suppliers to have customized forging capabilities - such as optimizing the forging structure based on the battery pack size and reducing redundant weight through topological optimization design. At the same time, pay attention to the production cycle. The delivery cycle of batch orders should be controlled within 45 days to meet the rapid iteration requirements of vehicle models.

Summary

The gap between the chassis of new energy vehicles and those of traditional fuel vehicles essentially lies in the difference of "forging application concepts" : the former regards forgings as its "core competitiveness" and resolves the contradiction between driving range and safety through integrated, lightweight and high-precision forgings. The latter treated the forging as a "supplementary component" and failed to realize its true value. With the development of the new energy vehicle industry, forgings have become a "must-win territory" for chassis upgrades. Choosing high-quality and highly adaptable forgings is the key for automakers to build product strength.

If you need to know more about the customized solutions for new energy vehicle chassis forgings, the performance test data of forgings made of different materials, or obtain the technical parameter comparison table of core forgings, please feel free to contact us at any time! We will provide you with high-quality forging products that meet automotive industry standards and professional technical support.