Premium Grade End cover

1.Material:42CrMo/45#

2.Machining accuracy:±0.01mm

3.Mold opening cycle:About 45 days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

7.Craft:Forging

Product Introduction:

The end cover is a key component in industrial equipment, mainly used to seal, protect the openings of the equipment or keep the openings in a closed state. It belongs to the category of disc cover parts. Its core functions include sealing, protection, support and connection. Although the end cover is small in size, it is the "safety guard" of industrial equipment. Its diverse designs are always centered around three core principles: reliability, environmental adaptability and high productivity. Looking ahead, with the development of new energy and intelligent manufacturing technologies, end covers will continue to break through and innovate in the directions of lightweight, intelligent and green design, becoming an indispensable "industrial guardian" for high-end equipment.

Product Advantages:

As a key component in industrial equipment, the end cover has its advantages mainly reflected in four aspects: sealing protection, structural support, material adaptability and economy. The following elaborates on the two core advantages of "high-efficiency sealing protection" and "structural support stability" :

1. High-efficiency sealing and protection: Dust-proof and water-proof

By sealing pipes, bearing boxes or equipment interfaces, end covers can effectively prevent dust, moisture and oil impurities from entering, creating a clean and stable operating environment for the internal components of the equipment. This feature makes it suitable for scenarios with high sealing requirements such as automotive engines and wind power equipment.

Ii. Structural Support Stability

The forged metal end cover can withstand axial loads up to 20 kilonewtons (kN). Its rib plate reinforcement design further enhances its resistance to bending and torsion, making it highly suitable for application in equipment that bears high loads, such as ore grinders and heavy machinery.

Production Process:

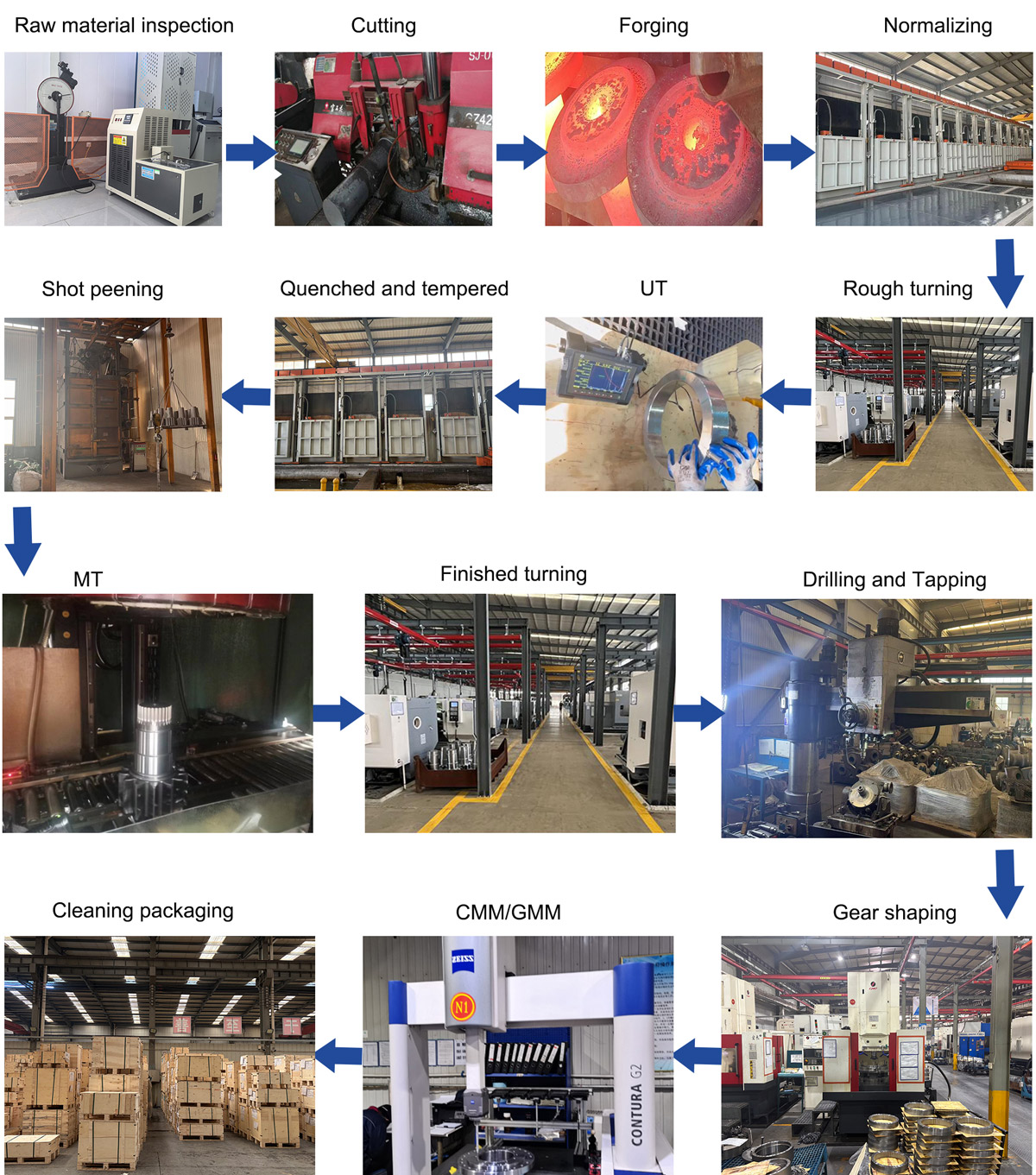

Raw material inspection→ Cutting→ Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → Shaping → CMM/GMM → Cleaning packaging

Packaging and Shipping

Our team is committed to the following pre-shipment protocols for all products:

First, every item undergoes thorough cleaning, clear labeling, and strict rust-preventive treatment to preserve its condition.

Next, a meticulous visual inspection is conducted to ensure each product meets our rigorous quality standards.

Lastly, the products are professionally packaged and stored in our organized warehouse, guaranteeing they are fully prepared for immediate dispatch when needed.

Company Strength:

Over the past three decades of steady growth, the company has proactively expanded its presence across both domestic and global markets. Its products find extensive application in key sectors including construction machinery, wind power generation, new energy vehicles, rail transit, petrochemicals, and mining machinery. The enterprise has forged in-depth collaborations with world-renowned corporations hailing from the United States, Canada, Germany, Italy, Belgium, Japan, and other countries. Notably, sales to overseas clients now account for over 50% of its total revenue. Domestically, it has also established long-term strategic partnerships with leading high-end equipment manufacturers such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. In terms of product competitiveness, its core forgings for planetary reducers and medium-to-large hook assemblies hold the top position in the domestic market in terms of market share.