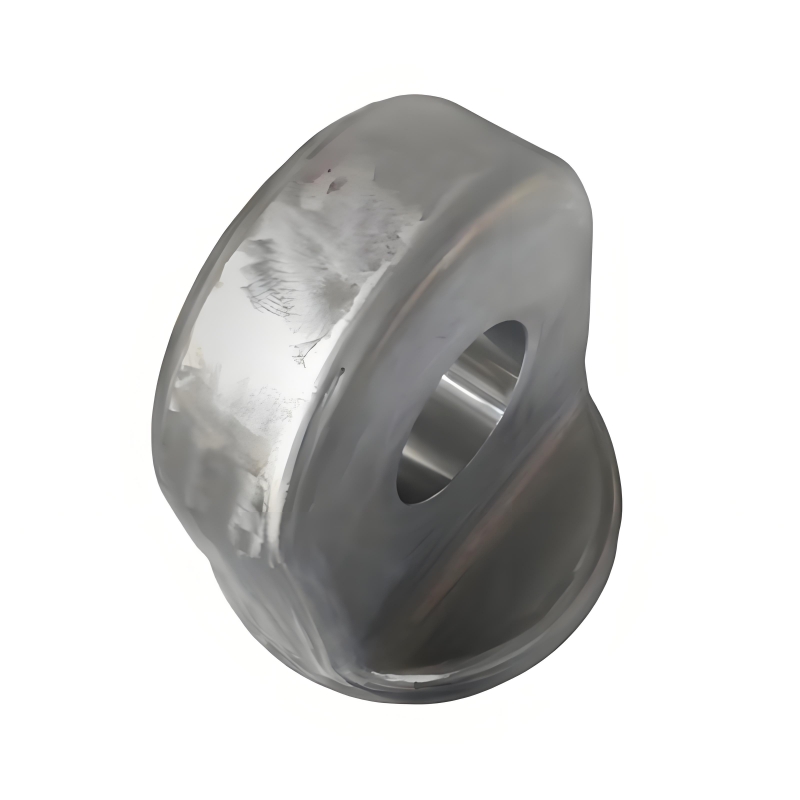

Wear Resistant Forged Hinges

1.Material:18CrNiMo7-6/20CrMnTi/35CrMo

2.Machining accuracy: ±0.1mm

3.Mold opening cycle: About 45 days

4.Customization: Fabricate tailor-made products that precisely align with your technical specifications

5.Advantages:

Full-process inspection

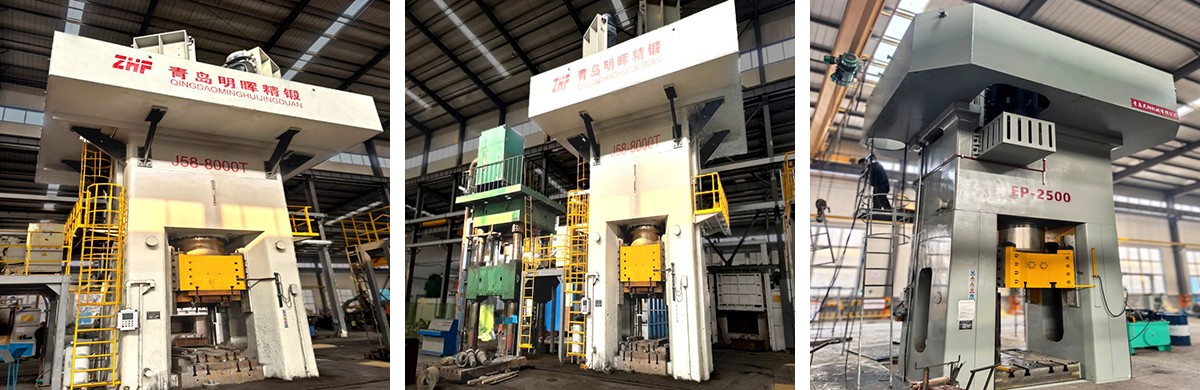

Full-process processing capability

Full-range products

6. Weight:We will ascertain the material usage and the weight of the finished products according to the drawings provided by the customers.

7.Craft:Forging

Product Introduction:

The hinges of crawler cranes and truck cranes are imperative connecting elements in lifting equipment. Serving as the "joints" between the enlarge and the important form of the crane, they play a fundamental feature in transmitting hundreds and making positive the flexible rotation and impervious operation of the boom. Whether it is the heavy - duty lifting responsibilities of crawler cranes or the flexible and rapid operations of truck cranes, the typical overall performance of ear hinges barring lengthen influences the safety, reliability, and work effectivity of the cranes.

Product Advantages:

The hinge (also recognized as the ear shaft or hinge seat) in cranes such as crawler cranes and truck cranes is a pivotal connection element for key factors like the boom, outriggers, and slewing mechanism. Its core attribute is to change loads, enable relative rotation between components, and make sure the steadiness and flexibility of the whole computer structure. It factors high-strength load change and fatigue resistance, high-precision hinging and movement flexibility, built-in hinging layout, wear-resistant flooring treatment, rapid assembly and disassembly, and optimized preservation costs.

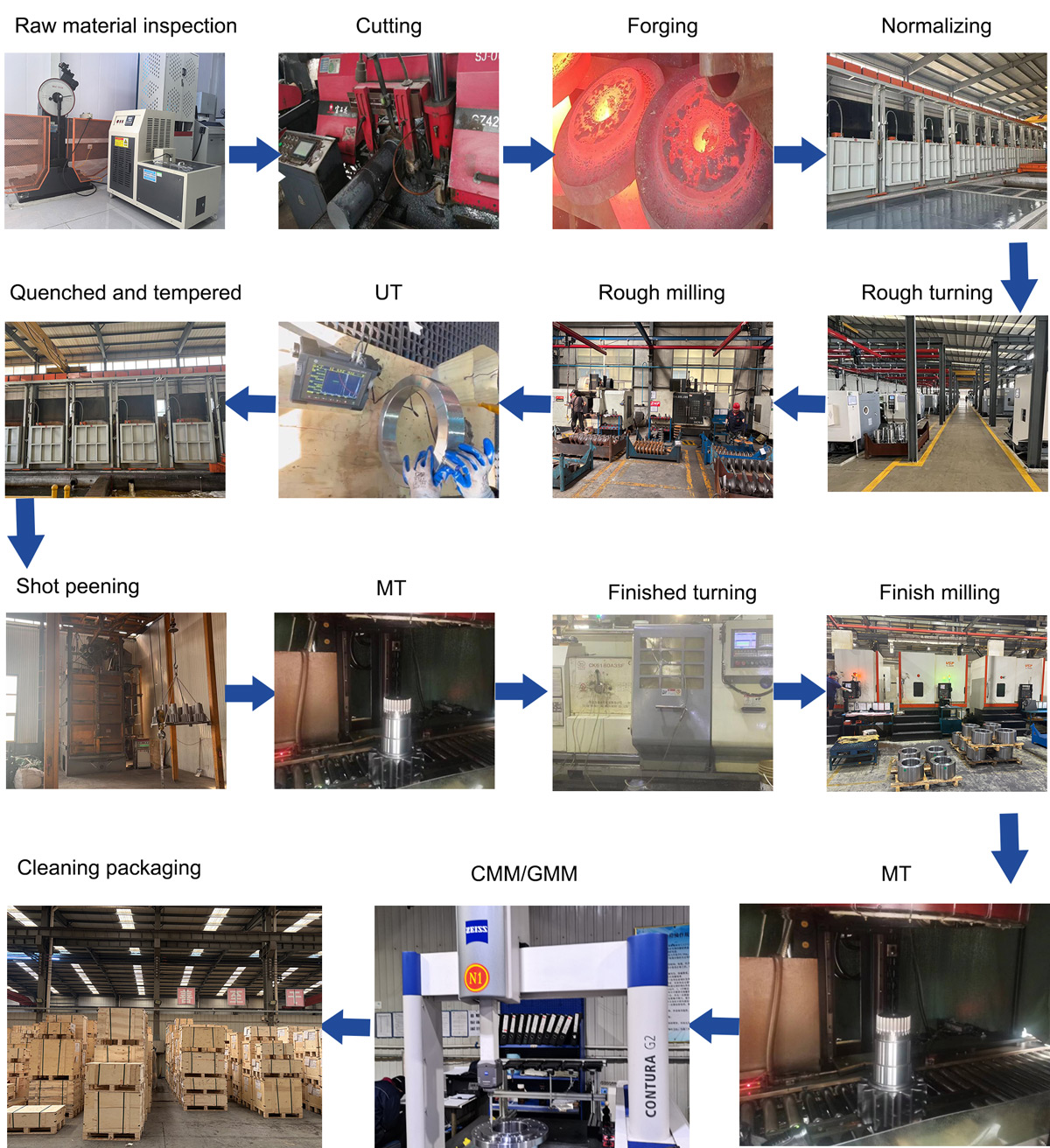

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Rough turning → Rough milling → UT → Quenched and tempered → Shot peening → MT → Finished turning → Finish milling → MT → CMM/GMM → Cleaning packaging

Packaging And Shipping:

Our professional crew follows a stringent superb manipulate technique for all orders. Prior to shipping, every product undergoes thorough cleaning, clear labeling, and reliable rust-proof treatment. After that, a whole seem inspection is carried out to make positive top-notch quality. Finally, we cautiously bundle and preserve the merchandise in our orderly warehouse, making certain they are geared up for at once delivery.

Company Strength:

The corporation has obtained certifications for ISO 9001 Quality Management System, ISO 14001 Environmental Management System, and ISO 45001 Occupational Health and Safety Management System from TÜV Rheinland. Its fantastic administration abilities have been recognized with the resource of world and domestic business enterprise leaders, and it has received severa honors such as Outstanding Supplier and Best Quality Award.