Cross Shafts Forging Parts

1.Material:17CrNiMo6-4/18CrNiMo7-6/20CrMnMo

2.Machining accuracy: ±0.1mm

3.Mold opening cycle: About 45 days

4.Customization: Manufacture custom-tailored products that strictly comply with your technical specifications.

5.Advantages:

100% process inspection

One-stop processing capability

Full-range product offering

6. Weight/Size:The calculation of material usage and final product weight shall be governed by the drawings furnished by the Client.

7.Craft:Forging

Product Introduction:

Within the petrochemical sector, cross shafts function as the linchpin of conventional coupling systems, tasked primarily with transferring torque and synchronized motion between shafts that operate on disparate axes across a range of mission-critical equipment—including high-pressure pumps, industrial compressors, and heavy-duty agitators that drive core production workflows. What sets these components apart is their exceptional ability to perform under the industry’s most grueling operating conditions, where they must reliably compensate for angular misalignments, axial shifts caused by thermal expansion of pipelines and machinery, and radial displacements stemming from prolonged vibration or installation tolerances. From withstanding extreme temperature fluctuations to resisting corrosion from hydrocarbon vapors and high-pressure fluid exposure, cross shafts are engineered to maintain structural integrity in environments that would compromise standard transmission parts. Their design—encompassing material grade (often high-strength alloy steels treated with quenching or carburizing for enhanced durability), bearing geometry, and load-distribution architecture—alongside their core mechanical performance, directly dictates the stability of interconnected equipment, the long-term reliability of entire transmission systems, and the operational safety of petrochemical facilities. A single cross shaft failure can trigger unplanned downtime, disrupt critical production lines, or even lead to hazardous material leaks, underscoring its status as an irreplaceable component for upholding seamless, secure petrochemical operations.

Product Advantages:

Within the petrochemical sector, cross shafts act as a cornerstone of mechanical transmission systems—including large-scale couplings and cross-shaft universal joints—serving as the primary component for transferring rotational motion and torque between intersecting or misaligned shafts across critical production equipment. The design specifications and overall mechanical performance of these cross shafts directly dictate the transmission efficiency, operational reliability, and on-site safety of the entire machinery assembly, as even minor performance lapses can disrupt core petrochemical workflows. Engineered with high tensile strength and superior fatigue resistance, cross shafts are fabricated using precision machining techniques to ensure tight dimensional tolerances and structural consistency. Equipped with advanced sealed, leak-proof configurations, they effectively prevent lubricating oil leakage while blocking the intrusion of external contaminants—such as dust, moisture, and corrosive hydrocarbon vapors prevalent in petrochemical environments. This robust design enables cross shafts to maintain long-term, stable operation even in the industry’s harsh, humid, and highly polluted working conditions, where exposure to aggressive media and continuous cyclic loading would quickly degrade standard transmission components. Their ability to withstand extreme operational stresses while preserving transmission integrity makes them an indispensable part of petrochemical mechanical systems, underpinning the uninterrupted performance of pumps, compressors, and agitators that drive key production processes.

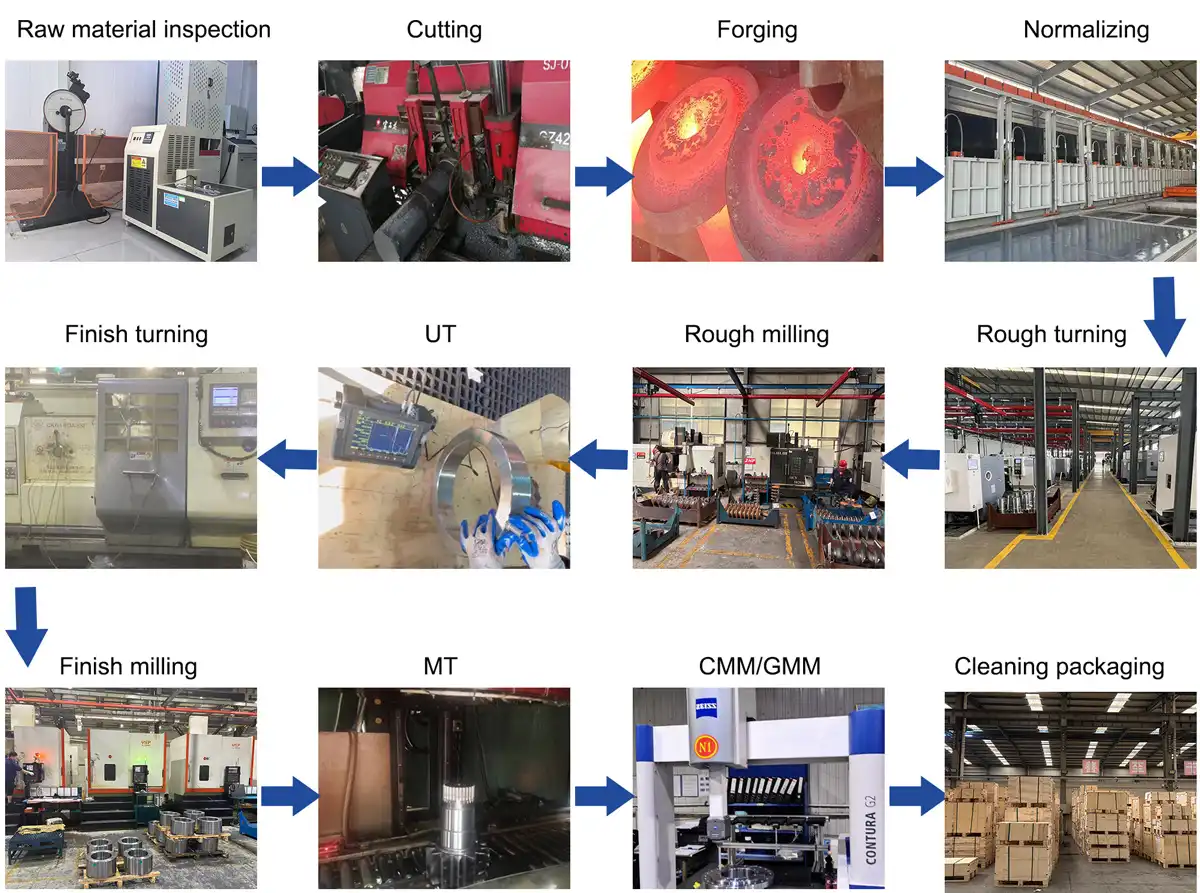

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Rough turning → Rough milling → UT → Finish turning → Finish milling → MT → CMM/GMM → Cleaning packaging

Packaging And Shipping:

Our dedicated quality assurance team enforces a stringent, end-to-end quality control framework for every single order, leaving no detail overlooked in upholding the highest product standards for our global clients. Prior to shipment, every component undergoes a three-stage pre-dispatch preparation process to ensure optimal condition and compliance with technical specifications: first, all products are subjected to a thorough, multi-step cleansing procedure—utilizing industrial-grade degreasers and high-pressure rinsing—to eliminate all manufacturing residues, including machining dust, lubricant buildup, and metal shavings that could compromise performance or cause corrosion over time; second, each item is affixed with clear, durable labels containing critical information such as part number, batch code, material grade, production date, and compliance certifications, enabling full traceability across the supply chain and simplifying inventory management for our partners; third, a uniform, industrial-grade rust-proof coating is applied via automated spraying or dip-coating processes, forming a protective barrier that shields metal components from oxidation, moisture, and harsh environmental exposure during transit and storage. Following this preparation, a comprehensive visual and dimensional inspection is executed by our certified QC specialists, who verify that each product meets strict tolerance thresholds, surface finish requirements, and structural integrity benchmarks—rejecting any units with even minor deviations to guarantee flawless quality. Finally, the inspected and approved products are carefully packaged using custom-fitted, shock-absorbent materials (including foam inserts and moisture-resistant wrapping) to prevent scratches, dents, or structural damage during transportation. These packaged items are then systematically stored in our well-equipped, climate-controlled warehouse, where inventory is tracked via a real-time logistics management system to ensure immediate availability for dispatch the moment delivery is requested, minimizing lead times and ensuring on-time fulfillment for every customer order.

Company Strength:

Founded in 1986, Zhangqiu Heavy Forging Co., Ltd. has upheld a market-driven operational strategy and customer-centric service philosophy for more than three decades, evolving from a regional forging workshop into a nationally recognized and internationally competitive heavy-duty forging specialist. Backed by its unwavering focus on product precision and tailored client solutions, the company has garnered enduring trust from both domestic enterprises and global partners spanning the automotive, petrochemical, construction machinery, and new energy sectors, charting a trajectory of steady, innovation-led growth that sets industry benchmarks for reliability and technical excellence. Today, Zhangqiu Heavy Forging operates a comprehensive, integrated manufacturing ecosystem encompassing six core business divisions—die forging, free forging, ring rolling, precision machining, lifting hook fabrication, and riveting & welding—enabling end-to-end production capabilities that eliminate supply chain bottlenecks for clients. Spanning a sprawling 300,000-square-meter production campus with 120,000 square meters of modernized workshop space, the facility is equipped with state-of-the-art forging presses (including 5,000-ton hydraulic presses and precision ring rolling mills), CNC machining centers, and advanced quality testing laboratories, ensuring full control over every stage of production from raw material forging to finished component delivery. With a dedicated workforce of over 1,000 skilled professionals—including a 120-strong R&D team of metallurgical engineers and process specialists—the company achieves an annual output value exceeding 1 billion yuan, delivering high-performance forged components such as EV hubs, reducer gears, petrochemical cross shafts, and heavy-duty lifting hooks to clients across 20+ countries and regions. Its commitment to quality is further underscored by compliance with international standards including ISO 9001, IATF 16949, and API specifications, as well as its ability to provide customized forging solutions that meet the most stringent technical requirements of industries ranging from automotive powertrains to petrochemical transmission systems. Beyond manufacturing scale, Zhangqiu Heavy Forging differentiates itself through continuous technological innovation: its near-net-shape forging processes reduce material waste by 25% while cutting downstream machining time, and its digital quality management system enables real-time traceability and process optimization. This blend of scale, technical expertise, and customer focus positions the company as a trusted strategic partner for clients seeking reliable, high-quality forged components to power their critical operations.