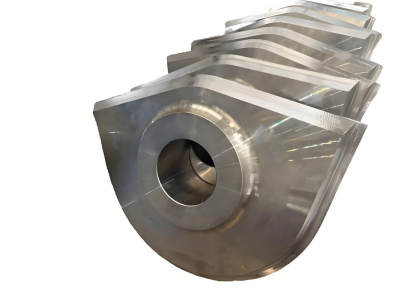

Planetary Spindle Shaft Parts

1.Material:42CrMo/40Cr

2.Machining accuracy:±0.01mm

3.Mold opening cycle:About 45 days

4.Craft:Forging

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

Product Introduction:

Support shafts are essential foundational components in diverse mechanical systems, serving key functions like securing rotating parts (gears, pulleys, impellers), transferring axial and radial loads, maintaining motion precision, and reducing frictional wear during continuous operation. These precision-machined cylindrical parts rarely operate alone; instead, they form integrated support assemblies with anti-friction bearings (to cut rotational resistance), durable seals (to block dust, moisture, and corrosives), and specialized lubrication systems (to minimize wear and extend service life). Deployed across heavy industrial machinery, high-precision robotics, automotive powertrains, and petrochemical equipment, support shafts act as the “mechanical backbone” of these systems, underpinning operational stability, motion accuracy, and long-term reliability. Their design—including material choices (typically high-strength or heat-treated carbon alloy steels), dimensional tolerances, and surface finish—directly impacts the performance of connected rotating components; even small deviations in straightness or concentricity can trigger vibration, premature failure, or full system downtime. For high-stress scenarios involving extreme torque or temperature swings, support shafts may undergo advanced treatments like induction hardening, nitriding (to boost surface hardness), or precision forging (to refine grain structure and enhance load-bearing capacity), ensuring they withstand harsh industrial demands.

Produt Advantages:

As core mechanical components, support shafts distinguish themselves through optimized structural design, superior material performance, versatile functionality, and exceptional cost-effectiveness, making them irreplaceable in a wide array of industrial and automotive systems. Engineered to deliver robust high-load-bearing capacity and unwavering operational stability, these shafts feature compact, integrated designs that seamlessly integrate into tight equipment layouts while eliminating the need for excessive auxiliary components, streamlining assembly and reducing overall system footprint. Whether deployed in heavy-duty industrial machinery that demands continuous radial and axial load resistance or high-precision robotics that rely on micron-level motion stability, support shafts consistently balance performance and practicality, offering long service life and low maintenance costs that enhance the total cost of ownership for end-users. Driven by the advancement of Industry 4.0 and the growing demand for smarter, more durable high-end equipment, the future of support shaft innovation is poised to break new ground across three key frontiers. First, the adoption of lightweight carbon fiber composite materials will drastically reduce shaft weight without compromising structural strength, a critical upgrade for electric vehicle powertrains and aerospace systems where weight reduction directly translates to energy efficiency and performance gains. Second, the integration of embedded sensors—such as strain gauges and temperature monitors—will enable real-time condition monitoring, allowing for predictive maintenance that minimizes unplanned downtime and extends component lifespan by detecting stress, wear, or overheating before failures occur. Third, laser cladding remanufacturing technology will revolutionize sustainability by repairing worn or damaged shaft surfaces with high-performance alloy coatings, restoring components to original specifications (or even upgrading their durability) while cutting down on material waste and replacement costs. Together, these innovations will ensure support shafts continue to underpin the evolution of high-end equipment, meeting the increasingly stringent demands of smart manufacturing, green energy, and precision engineering sectors.

Production Process:

Raw material inspection→ Cutting→ Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → Shaping → CMM/GMM → Cleaning packaging

Packaging and Shipping

To safeguard the quality, structural integrity, and on-schedule delivery of your order, our dedicated operations and quality assurance teams will implement a stringent, multi-phase pre-shipment validation and preparation workflow, leaving no detail to chance for end-to-end product reliability: First, all components undergo a comprehensive pre-treatment regimen tailored to their material composition and intended application: each unit is subjected to a precision cleaning process to eliminate machining residues, metal shavings, and lubricant buildup; specialized rust-proofing measures—from industrial-grade anti-rust oil for carbon steel parts to corrosion-resistant coatings for alloy components—are applied to fortify against environmental damage during transit; and every item is affixed with durable, scannable labels containing critical traceability data, including model number, batch code, production date, and compliance certifications for full supply chain transparency. Next, our certified QC specialists conduct a rigorous, item-by-item inspection of all pre-treated products. This verification covers three core pillars: confirming the uniformity and adhesion of rust-proofing layers to prevent premature oxidation, cross-checking label accuracy against order specifications to avoid misidentification, and validating that all dimensions, surface finishes, and performance metrics align with industry and client-specific standards. Any units failing inspection are immediately flagged for targeted rework or full replacement, with a documented review process to address root causes and prevent recurrence. Finally, products that pass the full inspection are packaged using industry-leading, custom-fitted protective materials—ranging from shock-absorbent foam inserts for high-precision components to waterproof, tear-resistant wrapping for heavy-duty forged parts—with packaging solutions calibrated to each item’s size, weight, and fragility. These secured units are then stored in our climate-controlled warehouse, where a real-time inventory management system tracks stock levels and order status 24/7, ensuring we can fulfill your dispatch instructions promptly and efficiently, whether for bulk shipments or just-in-time delivery to your production line.

Company Strength:

After three decades of robust, dynamic growth, the company has firmly established a prominent foothold in both domestic and international markets, offering a comprehensive portfolio of precision-forged components tailored to meet the mission-critical operational needs of high-priority industries. Its product lineup serves a diverse array of sectors, including construction machinery, wind energy, new energy vehicles, rail transit, petrochemical processing, and mining equipment, with each component engineered to align with the unique performance and durability demands of its target industry. On the global stage, the company has cultivated deep, long-standing partnerships with leading enterprises across North America (the U.S. and Canada), Europe (Germany, Italy, Belgium), and Asia (Japan). This extensive international footprint is underscored by overseas revenue accounting for over 50% of its annual total sales, a clear testament to its competitive edge and reputation for quality in the global marketplace. Domestically, it has forged strategic alliances with China’s top-tier high-end equipment manufacturers, including Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. These collaborations have not only strengthened supply chain integration and streamlined production synergies but also driven joint research and development initiatives, fostering innovation in advanced forging technologies and component design. A defining hallmark of the company’s market strength lies in its flagship offerings: planetary reducer core forgings and medium-to-large lifting hook assemblies. Both product lines hold the number-one domestic market share in their respective categories, solidifying the company’s position as a leader in China’s high-end equipment component sector and demonstrating its unmatched expertise in precision forging for critical industrial applications.