Welded Seamless Transformer Oil Tank Shell

1.Material:Q355

2.Machining accuracy: ±1.5mm

3.Mold opening cycle: About 0 days

4.Customization: Deliver custom-engineered products that meet your exact technical requirements

5.Advantages:

Full-process inspection

Full-process processing capability

Full-range products

6. Weight:The material consumption and finished product weight shall be determined based on the customer's drawings.

7.Craft: Welding

8.Size: Execute custom orders with 100% drawing compliance

Product Introduction:

As a crucial protective component of transformers, the welded transformer oil tank shell serves multiple functions, including containing insulating oil, protecting the internal iron core and windings, and maintaining a sealed environment. Its main body is formed by welding high-strength steel plates, creating a closed box structure. Through precise welding, the shell prevents the intrusion of external moisture and dust. Meanwhile, it ensures the stable operation of internal transformer components by facilitating the heat dissipation of insulating oil through circulation.

Product Advantages:

The transformer oil tank casing is a crucial component of a transformer, primarily serving functions such as protecting internal components, insulation, heat dissipation, and sealing. The tank casing can withstand external impacts and provide rigid support for the transformer's internal components, ensuring that all parts remain stable under electromagnetic forces and preventing normal operation from being affected by deformation due to stress. As a sealed container, the tank casing enhances insulation performance, prevents moisture and leakage through sealing, and enables efficient heat dissipation. It can significantly reduce the failure rate of internal components of the transformer, minimize downtime losses caused by faults, improve the long-term operational reliability of the equipment, and reduce life-cycle costs.

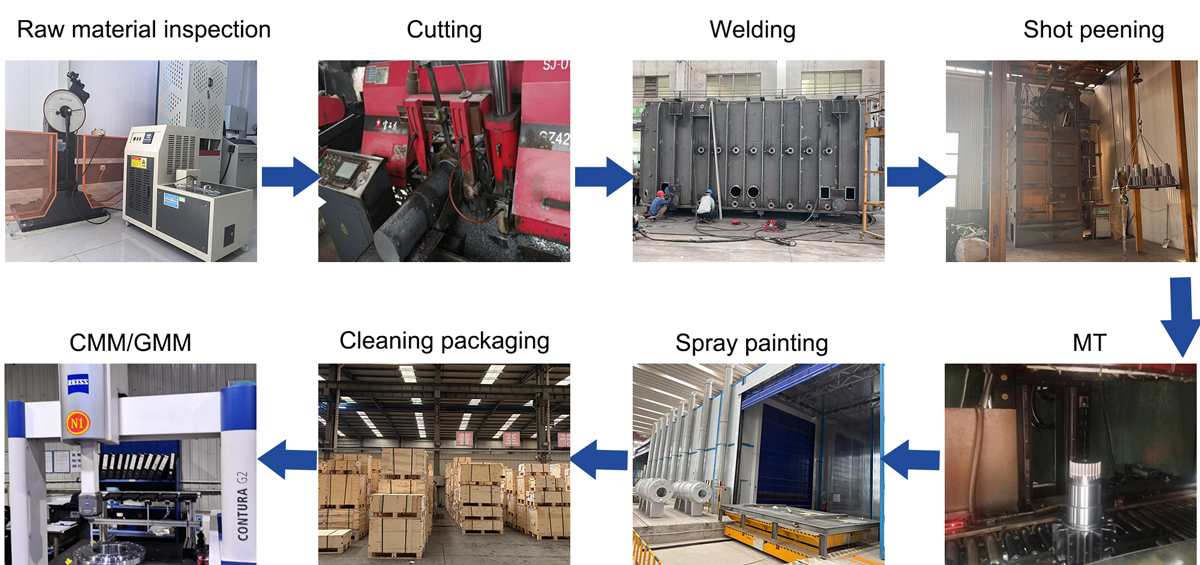

Production Process:

Raw material inspection → Cutting → Welding → Shot peening → MT→Spray painting→ Cleaning packaging →CMM/GMM

Packaging and Shipping:

Our dedicated team adheres to a strict quality control protocol for every order. Each product is meticulously cleaned, clearly labeled, and safeguarded with rust prevention measures before shipment. Subsequently, a rigorous appearance inspection is conducted to ensure flawless quality. Finally, we professionally package and store the products in our well-organized warehouse, guaranteeing prompt readiness for delivery.

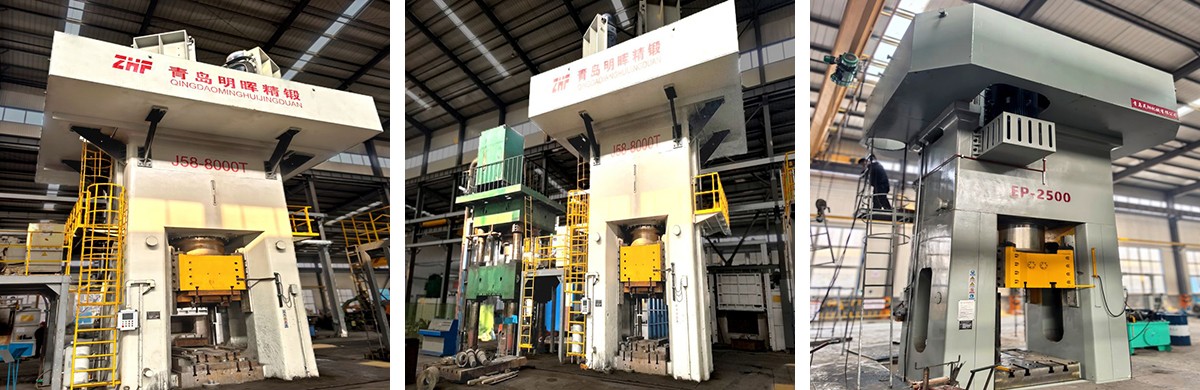

Company Strength:

The company adheres to the principles of streamlining all business processes and digitizing all procedures. Leveraging the efficient and fast "5G factory" internet, it integrates data from the PLM management system, ERP system, production MES system, and equipment management system. This integration has enabled digital management of business processes such as research and development, scheduling, work reporting, process transfer, shipping, and traceability. As a result, the efficiency of product research and development has been significantly enhanced, production cycles have been shortened, and the punctuality of customer deliveries has been ensured.