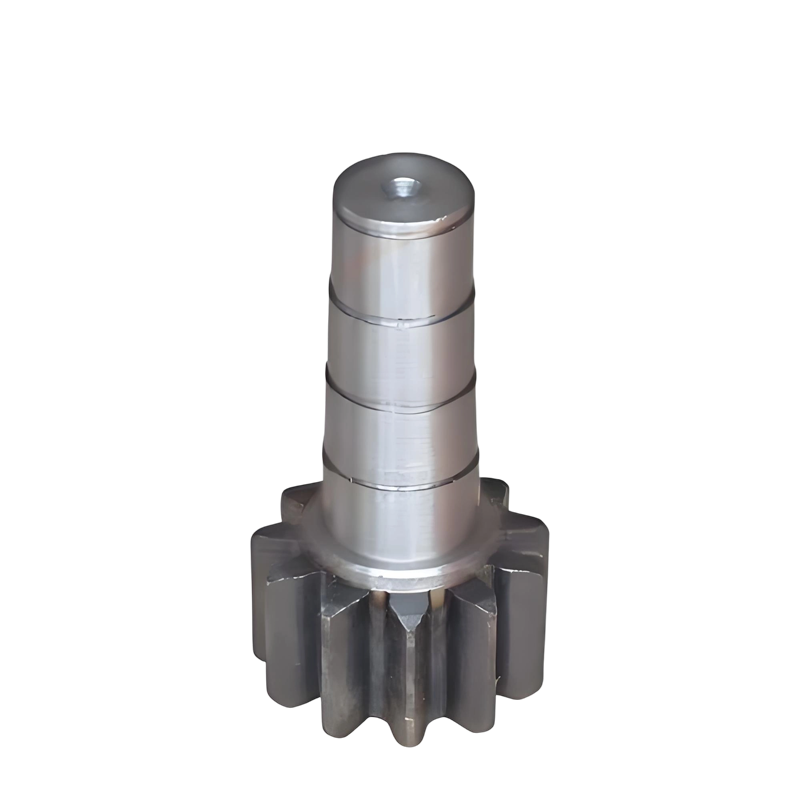

High Precision Output Gear Shaft

1.Material:17CrNiMo6-4/18CrNiMo7-6/20CrMnMo

2.Machining accuracy:

External cylindrical grinding: ±0.001mm

Tooth accuracy: Grade 5

3.Mold opening cycle:About 45 days

4.Customization: Customization is accepted.

5.Advantages:

Full-process inspection

Full-process processing capability

Full-range products

6.Weight/Size: Depend on client selection

7.Craft:Forging

Product Introduction:

The output gear shaft in a slewing speed reducer is a core transmission component connecting the power output end, mainly used to transmit the torque inside the speed reducer to external loads (such as slewing rings, gearboxes, etc.). Its design and performance directly affect the transmission efficiency, stability, and service life of the equipment.

Product Advantages:

The output gear shaft as a key component connecting the transmission system and the actuator in wind power and construction machinery slewing reducers, its design and performance directly impact the equipment's reliability, efficiency, and service life. Its core advantages lie in high load-bearing and impact resistance, high-precision transmission with low noise characteristics, fatigue resistance and wear resistance, multi-form interface adaptability, and adaptability to extreme environments.

Production Process:

Raw material inspection→Cutting→Forging→Normalizing→Rough turning→UT→Finished turning→Rolled spline→Gear milling→Carburizing and quenching→Tapping→Sandblasting→Thread turning→Cylindrical grinding→Gear grinding→Spline grinding→MT→CMM/GMM→Cleaning packaging

Before shipment, the products will be cleaned, labeled, rust-proofed, and undergo appearance inspection, and finally packed and stored in the warehouse.

Company Strength:

The company is equipped with 20 heavy forging production lines, primarily consisting of screw presses, die forging hammers, and large ring rolling machines. Among them, the 25-ton die forging hammer production line is the largest hammer forging equipment in China. It also has over 600 core machining and testing devices and 10 of the world's most advanced Aichelin nitriding and carburizing production lines. Within the industry, it possesses the capability for "full series, full industry chain" manufacturing and can offer customers "one-stop" customized services from blanks to finished products.