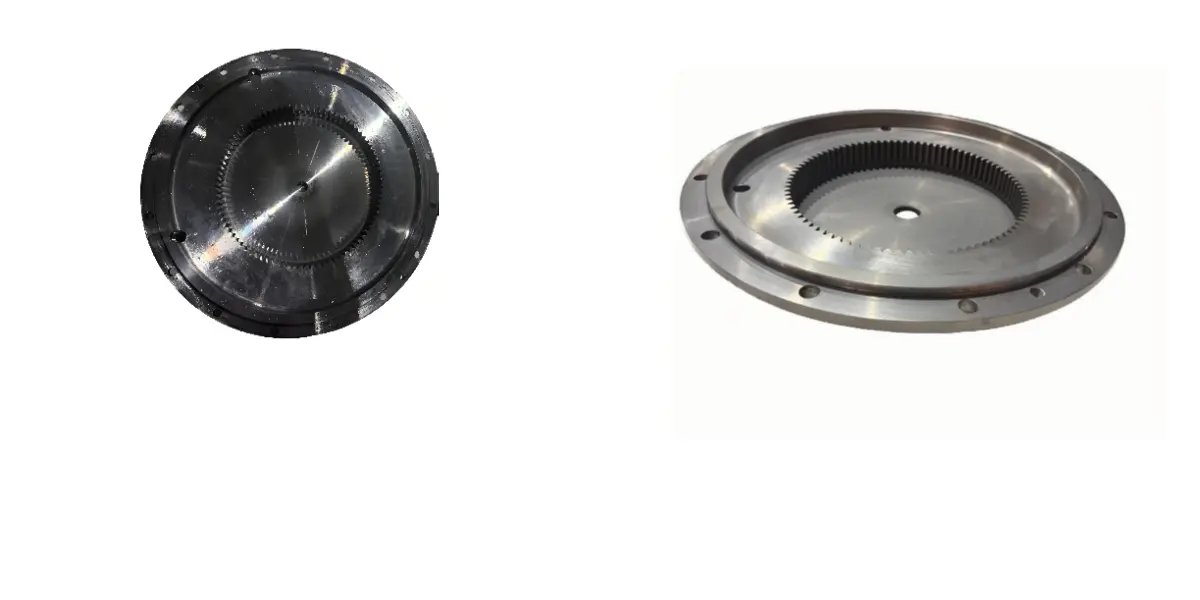

End Cover Forging Parts

1.Material:42CrMo/45#

2.Machining accuracy:±0.01mm

3.Mold opening cycle:About 45 days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

7.Craft:Forging

Product Introduction:

End covers stand as vital components in industrial machinery, designed to seal, shield, and securely enclose openings—falling under the category of disc-shaped cover parts. Beyond their basic form, they integrate four core functionalities: robust sealing to prevent leakage of lubricants or intrusion of contaminants, reliable protection for internal components against harsh operating conditions, structural support for rotating parts like bearings or shafts, and secure connection to equipment housings via precision fasteners. Though compact in size, end covers serve as the "unsung guardians" of industrial equipment, with their design consistently adhering to three fundamental principles: long-term operational reliability, adaptability to extreme environments (such as high temperatures, corrosion, or heavy vibration), and eco-conscious manufacturing processes that minimize material waste and energy consumption.

Product Advantages:

As essential components in industrial equipment, end covers deliver standout advantages across four core dimensions: efficient sealing and protection, robust structural support, versatile material adaptability, and exceptional cost-effectiveness—making them indispensable across diverse industrial sectors. In terms of efficient sealing and protection, end covers excel at safeguarding critical equipment interfaces, pipelines, and bearing housings by forming a tight barrier against external contaminants. They reliably block the ingress of dust, moisture, and oil-based impurities, creating a clean, stable operating environment for internal components. This sealing capability makes them ideal for demanding applications such as automotive engines (where they prevent lubricant leakage and debris intrusion) and wind energy turbines (which operate in outdoor, variable weather conditions requiring long-term waterproof and dustproof performance). For structural support and stability, end covers crafted from forged steel stand out for their exceptional load-bearing capacity—capable of withstanding axial loads of up to 20 kN. Their design often incorporates ribbed reinforcement structures that significantly enhance resistance to bending and torsion, enabling them to maintain structural integrity even under extreme mechanical stress. This robustness makes them perfectly suited for heavy-duty equipment like ore grinding mills (which endure continuous vibration and high torque) and large-scale industrial machinery, where stable support is critical to preventing component displacement and ensuring operational safety.

Production Process:

Raw material inspection→ Cutting→ Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → Shaping → CMM/GMM → Cleaning packaging

Cleaning and Packaging

Our dedicated operations team adheres to a rigorous, detail-oriented pre-shipment protocol to ensure every product reaches you in flawless condition, ready for immediate deployment:

First, all items undergo a comprehensive three-step preparation process tailored to their material and application: each unit is subjected to precision cleaning—using industry-grade degreasers and high-pressure rinsing—to eliminate machining residues, metal shavings, and lubricant buildup; durable, scannable labels are affixed, featuring critical traceability information such as model number, batch code, and production date for seamless inventory management; and targeted rust-proofing measures are implemented—from anti-rust oil coatings for ferrous components to corrosion-resistant treatments for alloy parts—to safeguard against environmental damage during transit and storage. Next, our certified quality control specialists conduct a meticulous, item-by-item inspection, verifying the effectiveness of rust-proofing layers, the accuracy of labeling data, and strict compliance with technical specifications and industry standards. Any product failing to meet our rigorous quality benchmarks is promptly flagged for rework or replacement, with full documentation to ensure accountability. Finally, the qualified products are carefully packaged using industrial-grade protective materials—including shock-absorbent foam inserts, moisture-resistant wrapping, and sturdy cartons—customized to each item’s size, weight, and fragility to prevent scratches, dents, or structural damage. These securely packaged products are then systematically stored in our well-organized, climate-controlled warehouse, where real-time inventory tracking ensures full visibility and readiness for immediate dispatch upon receipt of your shipping instructions.

Company Strength:

After three decades of dynamic, market-driven growth, the company has successfully expanded its footprint across both domestic and global landscapes, emerging as a trusted supplier of high-performance components for critical industries worldwide. Its product portfolio is widely utilized across key sectors, including construction machinery, wind energy, new energy vehicles, rail transit, petrochemical processing, and mining equipment—each tailored to meet the rigorous operational demands of these specialized fields. On the international front, the company has forged deep, long-standing partnerships with world-renowned enterprises spanning the U.S., Canada, Germany, Italy, Belgium, Japan, and beyond. This global collaboration is reflected in overseas revenue accounting for over 50% of its total annual turnover, a testament to its competitive edge and ability to meet international quality and reliability standards. Domestically, it has established strategic alliances with leading high-end equipment manufacturers such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear, fostering supply chain synergy and joint innovation in advanced component development. A standout achievement lies in its core product offerings: planetary reducer core forgings and medium-to-large lifting hook assemblies. Both product lines hold the top domestic market share in their respective categories, solidifying the company’s position as a leader in China’s high-end equipment component sector and underscoring its expertise in precision forging and heavy-duty component manufacturing.