Railroad Parts Driven Gear

1.Material:17CrNiMo6-4/18CrNiMo7-6/20CrMnMo

2.Machining accuracy:

Excircle: ±0.01mm

Tooth accuracy: Grade 5

3.Mold opening cycle:About 45 days

4.Advantages:

Stringent 100% process inspection ensures zero defects

Streamlined one-stop processing for efficiency and cost savings

Diverse product offering to meet all your needs

5.Weight/Size:Material usage and final product weight calculations shall be based on the drawings furnished by the Client.

6.Craft:Forging

Product Introduction:

The driven gear is a critical component of railway vehicles’ running gear, assuming four core roles: power transmission, carbody support, directional guidance, and braking torque transfer . Dubbed the "walking cornerstone" of rail transport, its performance directly dictates train safety and operational efficiency—any compromise can lead to vibration, track wear, or even critical malfunctions . Traditionally a conventional mechanical part, the driven gear is undergoing transformative evolution fueled by smart and lightweight technologies. Modern iterations are evolving into high-end intelligent components integrated with "real-time condition awareness + predictive maintenance capabilities" . This shift leverages embedded sensors to monitor vibration, temperature, and wear, feeding data into digital systems for remote health tracking and failure prediction—cutting unplanned downtime significantly . Parallel advancements in lightweight design further enhance its value. Adopting precision forging with high-strength alloys or composite materials reduces weight by up to 20% without sacrificing load capacity , boosting energy efficiency and reducing stress on adjacent components like axles . Forged construction eliminates internal defects, ensuring the gear withstands high torque and cyclic loads—critical for heavy freight and high-speed trains alike. In essence, the driven gear has transcended its mechanical roots to become an "intelligent node" in modern rail systems. By merging forging-enhanced robustness with digital connectivity, it delivers actionable insights that drive efficiency and safety, serving as a core enabler for next-generation railway networks.

Product Advantages:

In railway systems, a "driven gear" is defined as a gear component that operates by following the motion of a driving gear, without directly generating or supplying driving force itself . This critical part is predominantly integrated into the wheelset structures of railway vehicles—including passenger trains, freight carriages, and heavy-duty railway machinery—serving as a foundational element of the running gear system . A key advantage of driven gears lies in their simplified structure: they eliminate the need for independent driving devices (such as motors or hydraulic actuators), which reduces reliance on complex transmission components . This design simplification translates to tangible cost benefits, lowering expenses associated with manufacturing, installation, and long-term maintenance . Beyond cost efficiency, the absence of a driving system also reduces the overall weight of the gear assembly. This lightweight characteristic contributes to multiple operational improvements: it lessens the vehicle’s self-weight, alleviates stress on railway tracks, and enhances energy efficiency by minimizing power consumption during operation . Functionally, driven gears play vital roles in ensuring operational stability. They assist in track guidance, helping maintain the vehicle’s lateral position on the rails, and balance vehicle loads to distribute stress evenly across the wheelset . Additionally, their design allows flexible adaptation to varying traction requirements—whether in high-speed passenger service or heavy freight operations—while minimizing power loss during power transmission . This combination of structural simplicity, weight reduction, and functional reliability makes driven gears an indispensable component in modern railway systems, supporting both efficiency and safety.

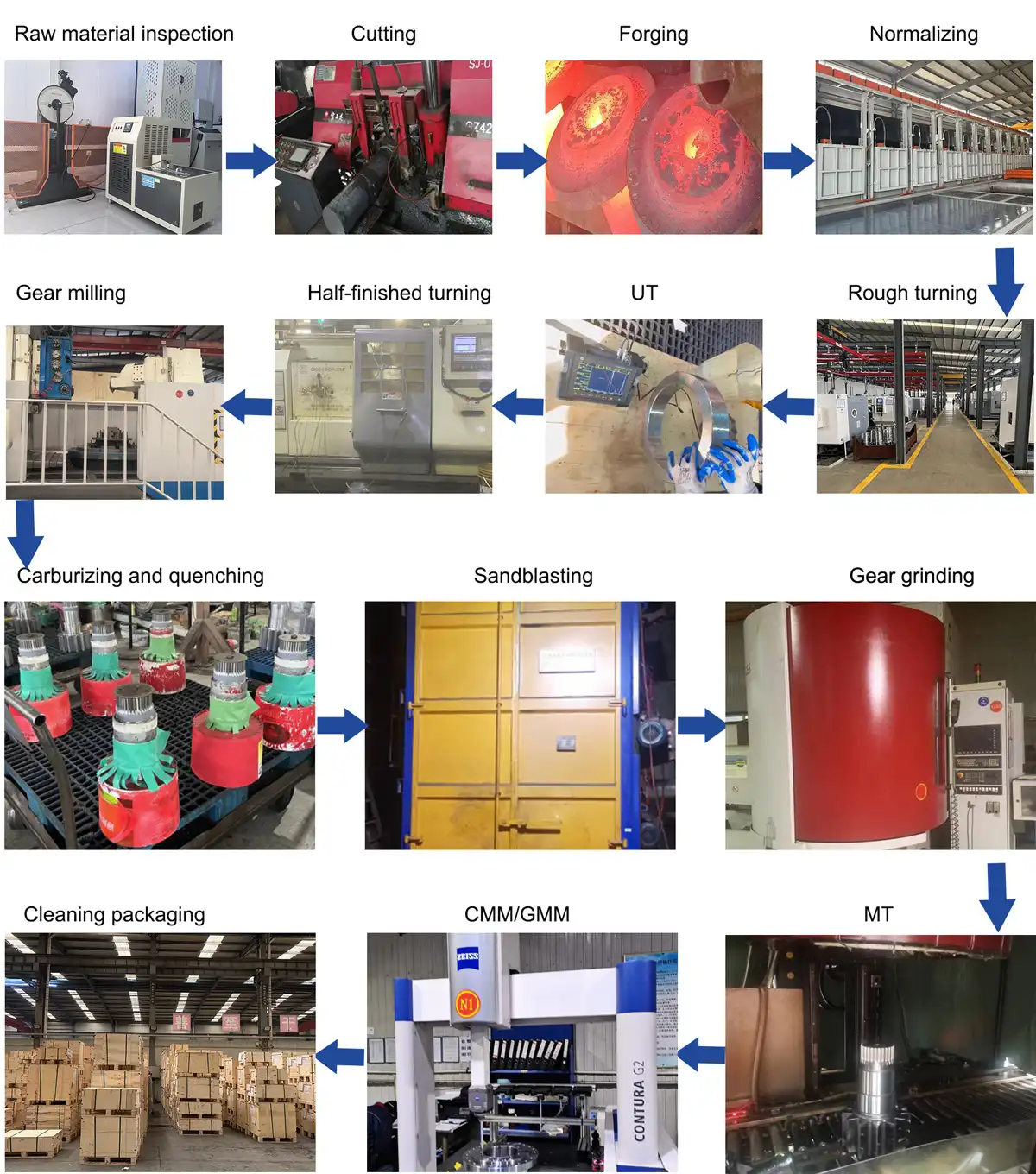

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Rough turning → UT → Half-finished turning → Gear milling → Carburizing and quenching → Sandblasting → Gear grinding → MT → CMM/GMM → Cleaning packaging

Packaging And Shipping:

For every order, our specialized team enforces a rigorous, multi-stage quality control protocol to guarantee product integrity and readiness for shipment:

First, we conduct comprehensive pre-shipment preparation tailored to industrial standards . Each unit undergoes precision cleaning to eliminate machining residues and surface contaminants, followed by the application of batch-specific, scannable labels for full traceability. To shield against corrosion during transit, we apply targeted rust-resistant treatments—such as industrial-grade anti-rust oil for metal components or corrosion-inhibiting coatings for alloy parts . Next, our quality assurance (QA) specialists perform meticulous inspections aligned with acceptance quality limit (AQL) standards . This verification process includes three critical checks: assessing surface finish for smoothness and consistency, validating label accuracy against order specifications, and confirming the integrity of anti-corrosion treatments to ensure long-term protection . Any non-conforming items are immediately flagged for rework or replacement to maintain our quality benchmarks. Finally, we prioritize logistics readiness with professional packaging engineered for transit resilience . Depending on product size, weight, and fragility, we use industrial-grade materials such as reinforced wooden crates for heavy machinery parts or shock-absorbent bubble wrap paired with double-wall corrugated boxes for smaller components . All packaged items are stored in our organized warehouse, where inventory is tracked in real time to enable rapid turnaround and on-demand dispatch . Rest assured, every order adheres to stringent quality requirements—from material protection to packaging durability—ensuring it arrives in pristine condition, ready for immediate deployment.

Company Strength:

The organization stands out in quality assurance and precision control, underpinned by a world-class portfolio of inspection and testing equipment that reflects its unwavering commitment to manufacturing excellence. At the core of its quality infrastructure lies a suite of cutting-edge instruments sourced from global industry leaders: imported high-precision spectrometers for elemental composition analysis, nitrogen-hydrogen-oxygen analyzers for quantifying gas content in materials, Zeiss metallographic microscopes for microscopic structure evaluation, Zeiss coordinate measuring machines (CMMs) for dimensional accuracy verification, and M2M ultrasonic phased array flaw detectors for non-destructive testing (NDT). Each instrument is strategically deployed to form an end-to-end quality validation system that leaves no critical parameter unmonitored. The imported spectrometers deliver detection limits as low as 0.002 μg/ml and precision with RSD ≤ 0.5%, enabling rigorous verification of raw material composition to ensure compliance with alloy grade standards—eliminating risks of material mismatch at the very start of production. Complementing this, nitrogen-hydrogen-oxygen analyzers pinpoint trace gas elements that could compromise material toughness, a critical step for components used in high-stress applications like railway gears or construction machinery parts. For microscopic and dimensional quality control, the organization leverages Zeiss’s industry-leading technology. Its Zeiss metallographic microscopes reveal grain structure, inclusions, and heat treatment effects at the cellular level, ensuring forged components achieve the desired mechanical properties. Meanwhile, Zeiss CMMs—such as models from the Prismo or Xenos families—deliver unmatched accuracy down to 0.2 + L/1000 μm, capable of scanning complex geometries to verify dimensions, shape, and position tolerances with micron-level precision. The dynamic rigidity of these CMMs, paired with air bearings and temperature insulation, ensures reliable measurements even during high-speed scanning of large workpieces. When it comes to non-destructive testing, the M2M ultrasonic phased array flaw detectors elevate the organization’s capability to identify hidden defects without damaging components. These advanced devices, featuring 64x64 channel configurations and real-time TFM (Total Focusing Method) imaging, excel at detecting internal cracks, pores, and weld defects in forged parts, pipelines, and heavy machinery components. Unlike conventional NDT tools, they support multiple scanning modes (A, B, C, S scans) and flexible probe configurations, making them adaptable to both lab-based inspections and on-site testing of large assemblies. This integrated equipment ecosystem empowers the organization with comprehensive inspection capabilities spanning the entire production lifecycle: from validating raw material composition and performance to certifying dimensional accuracy and structural integrity of finished products. Such thorough quality control not only ensures compliance with global standards like ASME, API, and EN but also prevents catastrophic failures, reduces maintenance costs, and extends the service life of end products. For industries ranging from railway manufacturing to petrochemical equipment—where safety and reliability are non-negotiable—this commitment to precision positions the organization as a trusted partner capable of delivering components that meet the most stringent quality demands.