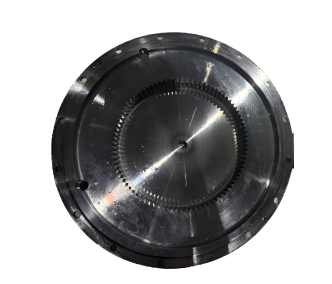

Precision Engineered End Cover

1.Material:42CrMo/45#

2.Machining accuracy:±0.01mm

3.Mold opening cycle:About 45 days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

7.Craft:Forging

Product Introduction:

End covers are key elements in industrial tools used to seal, protect, or impervious openings. They belong to the class of disc cowl components. Their core features consist of sealing, protection, support, and connectioAlthough a small component, the stop cowl acts as the "safeguard" of industrial equipment. Its assorted plan constantly revolves round three core principles: reliability, environmental adaptability, and environment friendly production.Looking ahead, with the development of new strength sources and sensible manufacturing, give up covers will proceed to destroy new floor in the instructions of lightweight, intelligent, and eco-friendly design. They will turn out to be an necessary "industrial guardian" for high-end equipment.

Product Advantages:

End covers, as crucial elements in industrial equipment, display blessings in sealing and protection, structural support, cloth adaptability, and financial benefits.Efficient Sealing and Protection | Dustproof and Waterproof:By sealing pipelines, bearing housings, or gear interfaces, they successfully block the ingress of dust, moisture, and oil contaminants, making sure a smooth surroundings for inside components. This makes them appropriate for functions such as car engines and wind energy equipment.Structural Support and Stability:Forged metal quit covers can face up to axial masses of up to 20 kN. Their rib-reinforced plan enhances bending and torsional resistance, making them perfect for use in ore grinding mills and heavy machinery.

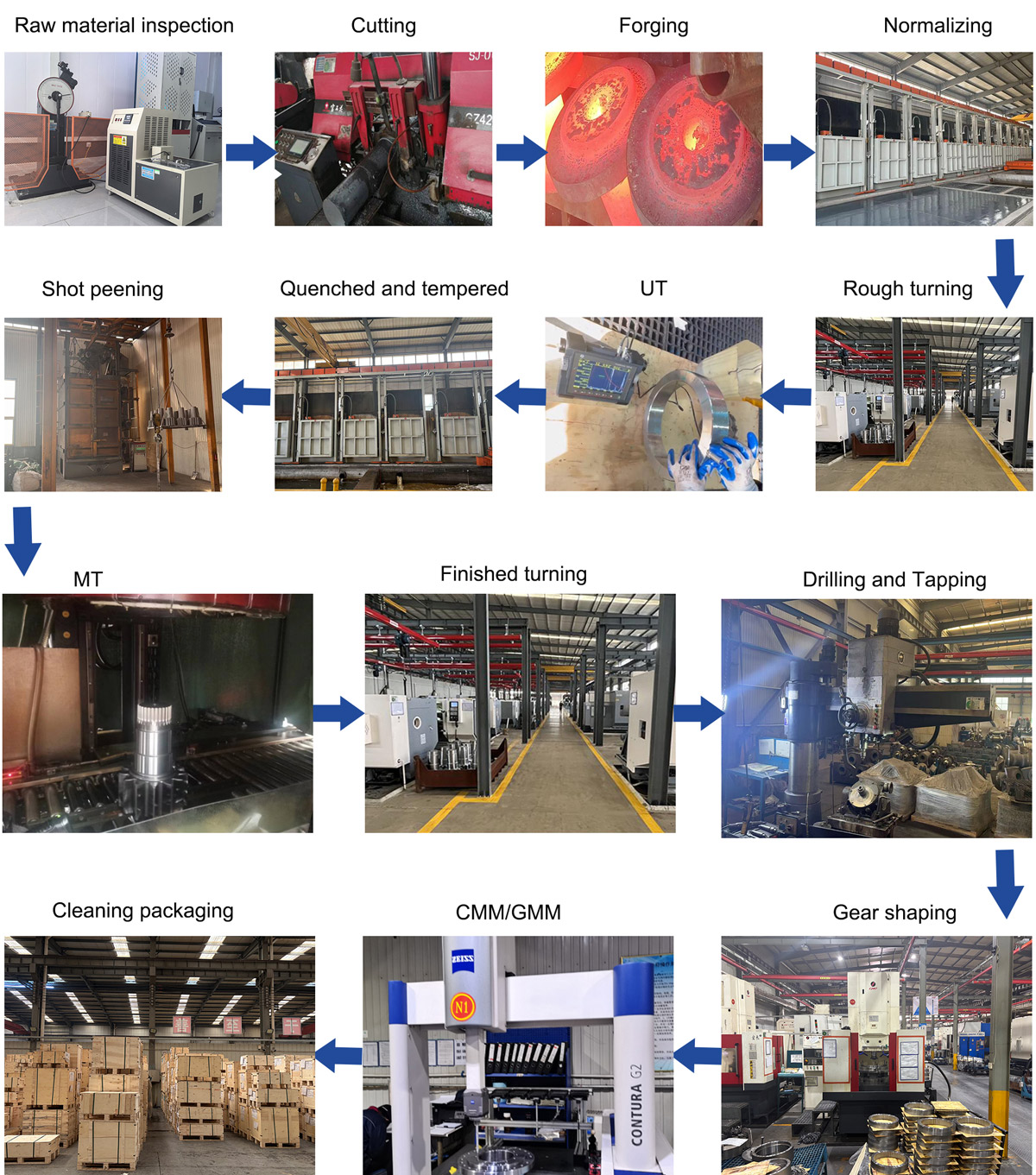

Production Process:

Raw material inspection→ Cutting→ Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → Shaping → CMM/GMM → Cleaning packaging

Our team will:

Clean, label, and take a appear to be at rust-proofing to all merchandise earlier than than shipment;

Perform a meticulous showcase up inspection;

Finally pack the merchandise and hold them in our warehouse, making high-quality readiness for dispatch.

Company Strength:

Over the previous 30 years of lively development, the company has aggressively prolonged into each and every and every and each home and world markets. Its merchandise are significantly used in fields such as setting up machinery, wind electrical strength generation, new electrical electrical energy vehicles, rail transit, petrochemicals, and mining machinery. The employer has set up in-depth cooperation with world-renowned groups in the United States, Canada, Germany, Italy, Belgium, Japan, and notable countries, with far-off areas capital patron income accounting for expanded than 50%. It has in addition standard strategic partnerships with home predominant high-end equipment producers such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. Among its products, the market share of planetary reducer core forgings and medium-to-large lifting hook assemblies ranks first in the home market.