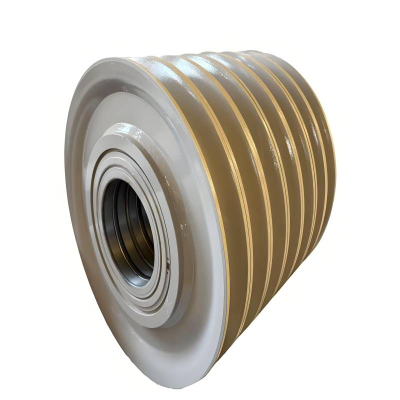

Sprocket Wheel Forging Parts

1.Material:42CrMo

2.Machining accuracy:

Excircle: ±0.01mm

3.Mold opening cycle:About 45days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Craft:Forging

Product Introduction:

The sprocket wheel serves as a pivotal component in the power transmission systems of petrochemical facilities, where its overall performance directly dictates the continuity and safety of industrial production processes. As a linchpin for ensuring the stable, hazard-free operation of petrochemical plants, it plays an irreplaceable role in maintaining uninterrupted workflow and mitigating operational risks. At its core, the sprocket’s primary function lies in power conversion: through the precise, interlocking meshing of its teeth with a corresponding chain, it transforms the rotational force generated by drive units (including electric motors or hydraulic motors) into linear or cyclic motion for the chain. This mechanical transfer of energy then drives the operation of key load-bearing components across the facility, such as conveyor belts for transporting raw materials and finished products, as well as stirring shafts for blending chemical mixtures—underpinning the functionality of critical petrochemical production lines.

Product Advantages:

Crafted primarily from high-strength metallic alloys, sprockets undergo specialized heat treatment processes—including quenching and carburizing—to bolster surface hardness while preserving core toughness. This dual enhancement equips them to withstand extreme torque loads and impact forces without compromising structural integrity, a critical attribute for demanding industrial applications. Renowned for high and consistent transmission efficiency, sprockets excel in adapting to complex operating conditions, ensuring that production workflows remain uninterrupted even in challenging environments. Within the petrochemical sector, sprockets have emerged as indispensable core components for powering heavy-duty machinery and facilitating material conveyance, thanks to their unique combination of advantages: exceptional load-bearing capacity, robust resistance to harsh on-site conditions (such as corrosive fumes and temperature fluctuations), superior energy transmission efficiency, a compact structural design that saves installation space, and straightforward maintenance requirements that minimize downtime. The performance of these sprockets directly correlates with three pillars of petrochemical operations: production safety, process continuity, and overall operational economy. As such, they stand as irreplaceable key elements in the transmission systems that underpin petrochemical plant functionality, supporting everything from raw material handling to finished product transportation across the production lifecycle.

Production Process:

Raw material inspection→Cutting→Forging→Normalizing→Rough turning→Rough milling→UT→Quenched and tempered→Shot peening→MT→Finished turning→Finished milling→Drilling and Tapping→CMM/GMM→Cleaning packaging

Packaging And Shipping:

Our devoted team implements rigorous quality control protocols for each order; prior to shipment, all merchandise undergo thorough cleaning to eliminate manufacturing residues, clear labeling for convenient identification and traceability, and industrial-grade rust-proof coating for long-term protection, after which a comprehensive visual inspection is carried out to ensure flawless quality, and finally, the qualified products are carefully packaged and stored in our well-equipped warehouse, fully prepared for immediate dispatch to meet customer delivery timelines and uphold the consistent reliability of our shipments.

Company Strength:

The company’s industry-leading quality management system is at the forefront of digital transformation, integrating a fully automated, cloud-based platform to deliver end-to-end online oversight of core quality processes—including real-time defect feedback, standardized nonconformance review and disposition workflows, full-lifecycle quality traceability, and stratified auditing across all production tiers. Unlike traditional manual systems, this digital infrastructure enables seamless data synchronization from raw material sourcing and production processing to final inspection and delivery, allowing the quality team to capture, analyze, and resolve issues in real time; for instance, defect reports are automatically routed to the relevant department with pre-defined resolution timelines, while nonconformance cases are tracked through a centralized dashboard to ensure consistent, compliant decision-making aligned with ISO and industry-specific standards. The robust quality traceability module further provides granular visibility into every product’s journey, enabling rapid root-cause analysis for any quality deviations, while digital stratified auditing automates schedule management, documentation, and corrective action follow-ups, eliminating administrative bottlenecks and human error. This comprehensive digital overhaul has not only elevated the standardization of the company’s quality operations by 40% but also slashed the average issue resolution time by 50%, drastically improving the timeliness of problem handling and proactive risk mitigation; by leveraging data-driven insights from the platform, the team can also identify recurring quality trends and implement preventive improvements, reinforcing the company’s reputation as a technologically advanced, quality-centric partner capable of meeting the most stringent requirements of global clients across heavy forging, construction machinery, and new energy vehicle component sectors.