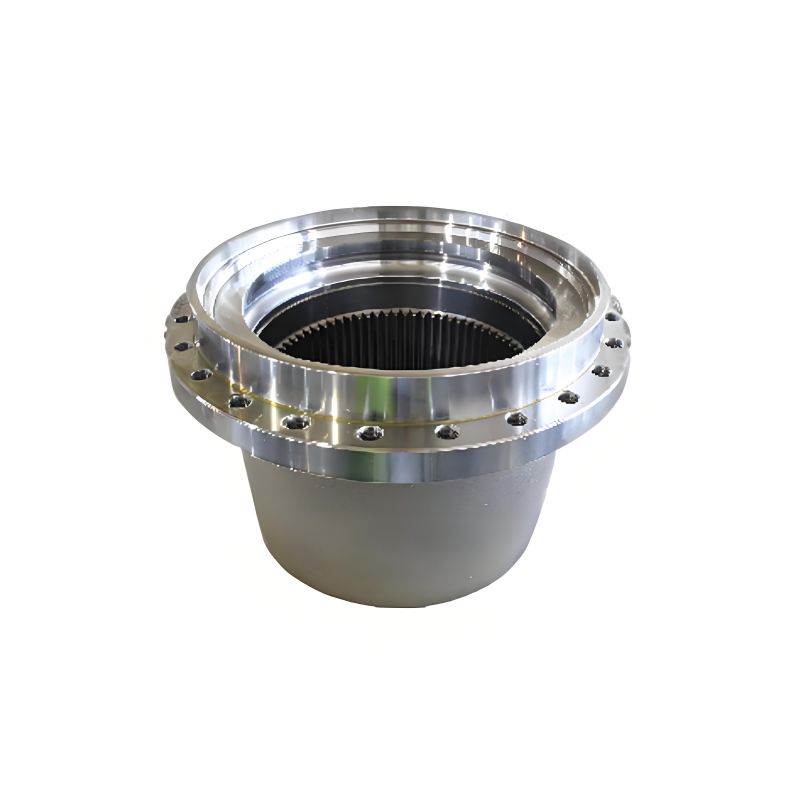

Gearbox Ring Gear

1.Material:42CrMo/40Cr

2.Machining accuracy:±0.01mm

3.Mold opening cycle:About 45 days

4.Craft:Forging

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

Product Introduction:

The internal gear ring stands as a pivotal component in mechanical transmission systems, falling under the classification of gear parts. Its structural characteristic is defined by its internal toothing design, which enables the transfer of both power and motion through meshing with external gears. Serving as a "precision connector" in power transmission, the design and arrangement of the internal gear ring directly influence the efficiency and service life of the equipment it is integrated into. Whether referring to the powder metallurgy gear rings used in automotive transmissions, the carburized steel gear rings employed in wind turbine gearboxes, or the nylon coupling internal gear rings found in robotic joints, their value is reflected in three key aspects: high-precision meshing performance, reliable force transmission capabilities, and strong environmental adaptability.

Product Advantages:

As a critical element in mechanical transmission systems, the gear ring is notable for its high transmission efficiency, compact structure, robust load-bearing capacity, and impact resistance. It features an annular internal tooth configuration, which meshes with external gears (like planetary gears and sun gears) to attain a transmission efficiency exceeding 95%, all while minimizing power loss. Its space-saving design renders it particularly suitable for applications where space is at a premium, allowing for seamless integration into intricate transmission systems. In comparison to straight-tooth designs, helical-tooth gear rings enhance load-bearing capacity by 15% to 20%. This structural optimization improves the contact area between gear teeth, alleviating stress concentration and in turn extending the component’s operational lifespan. For scenarios demanding exceptional durability, gear rings crafted from carburized and quenched steel offer a hardness range of 57 to 62 HRC—making them capable of withstanding the high-load, high-impact environments typical of metallurgical equipment and wind power installations. Practically, such gear rings are widely applied across multiple industries, encompassing automotive manufacturing, wind power generation, engineering machinery, aerospace, and medical device production.

Production Process:

Raw material inspection→ Cutting→ Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → Shaping → CMM/GMM → Cleaning packaging

Packaging and Shipping

Our team will carry out the following procedures:

First, we will clean all products, attach appropriate labels to them, and apply rust-proof treatment before shipment;

Next, we will conduct a thorough inspection of each product to ensure they meet the required standards;

Finally, we will pack the qualified products properly and store them in our warehouse, ensuring they are fully prepared for subsequent dispatch.

Company Strength:

Over the past three decades of dynamic development, the enterprise has proactively expanded into both domestic and global markets. Its products are widely utilized in sectors including construction machinery, wind power generation, new energy vehicles, rail transit, petrochemicals, and mining machinery. The company has established in-depth collaborative relationships with world-renowned enterprises across the United States, Canada, Germany, Italy, Belgium, Japan, and other countries, with overseas sales accounting for more than 50% of its total revenue. Furthermore, it has forged stable strategic partnerships with leading domestic high-end equipment manufacturers such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. Among its product portfolio, the core forgings for planetary reducers and medium-to-large hook assemblies hold the top position in terms of market share within the domestic market.