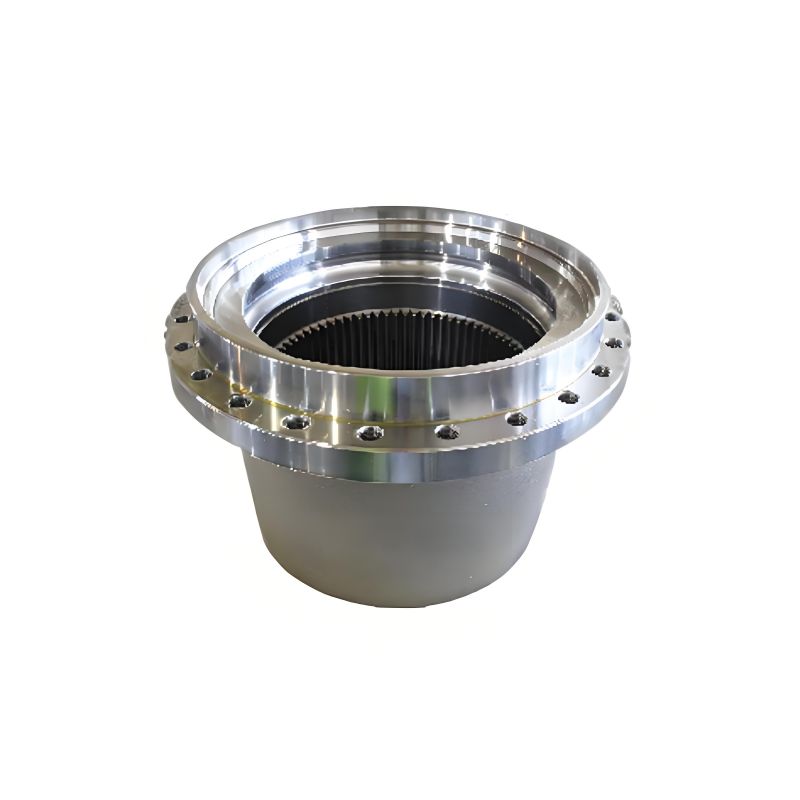

Forging Ring Gear

1.Material:42CrMo/40Cr

2.Machining accuracy:±0.01mm

3.Mold opening cycle:About 45 days

4.Craft:Forging

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

Product Introduction:

A key component of mechanical drive systems, the internal gear ring is classified as a gear-type part. Its defining structural feature is the placement of teeth on its inner circumference — a design that allows it to mesh smoothly with external gears, facilitating efficient power and motion transfer. Acting as a critical "power mediator" in transmission assemblies, its structural parameters and manufacturing precision directly influence the overall performance, stability, and durability of the host equipment. From powder metallurgy internal gear rings integrated into automotive gearboxes, to carburized and quenched steel variants for wind turbine drivetrains, and wear-resistant nylon internal gear rings in robotic articulations, these components excel in three core aspects: precise tooth engagement, consistent torque transmission, and robust adaptability to harsh operating environments.

Product Advantages:

As a cornerstone component in mechanical transmission systems, the gear ring stands out for its outstanding transmission efficiency, space-saving compact design, robust load-bearing capacity, and exceptional impact resistance—traits that make it irreplaceable in high-performance machinery. Defined by its annular structure with precisely machined internal teeth, it forms a tight, reliable meshing engagement with external gears (including planetary gears, sun gears, and pinions), facilitating power transfer with an efficiency exceeding 95%. This high efficiency minimizes energy loss, optimizes operational performance, and reduces long-term operational costs for the equipment it powers. Its space-efficient design is a key advantage, engineered to thrive in applications with constrained installation envelopes—from compact industrial gearboxes to complex automotive powertrains. The gear ring’s annular form allows for seamless integration into intricate transmission assemblies, enabling tight component packaging without sacrificing mechanical performance or durability. Constructed from high-strength alloy steels (often heat-treated for enhanced hardness and wear resistance), it boasts impressive load-bearing capabilities, capable of withstanding high torque, cyclic stresses, and shock loads in demanding operating environments. Additionally, its precision tooth profiling and optimized meshing geometry ensure smooth, low-noise operation, reducing vibration and extending the service life of both the gear ring and its mating components. These combined attributes make it a preferred choice for critical transmission systems across industries such as automotive, aerospace, construction machinery, wind power, and industrial automation.

Production Process:

Raw material inspection→ Cutting→ Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → Shaping → CMM/GMM → Cleaning packaging

Packaging and Shipping

Our team adheres strictly to a standardized, detail-oriented workflow to ensure uncompromising product quality and seamless pre-shipment preparation:

First, all products undergo a meticulous multi-stage cleaning process—utilizing ultrasonic cleaning technology to eliminate microscopic contaminants, surface residues, and machining debris—followed by the application of tailored, regulatory-compliant labels. These labels prominently display critical product information, including batch numbers, technical specifications, traceability codes, and safety certifications, while professional anti-rust protection measures are implemented based on product materials: metal components receive corrosion-inhibiting coatings or vacuum-sealed packaging, and sensitive parts are treated with moisture-resistant films to safeguard against oxidation during storage and transit. Next, each unit undergoes a comprehensive quality inspection conducted by certified engineers, leveraging precision tools such as digital calipers, coordinate measuring machines (CMMs), material performance testers, and functional verification equipment. The inspection encompasses three core dimensions: dimensional accuracy (verifying adherence to design tolerances within micron-level precision), material performance (validating hardness, tensile strength, and chemical composition), and functional integrity (testing operational performance, assembly compatibility, and structural stability) to ensure full compliance with predefined technical specifications and international quality standards (e.g., ISO 9001:2015). Any non-conforming items are immediately isolated, documented, and subjected to root-cause analysis, with corrective actions implemented before re-inspection and clearance. Once products pass inspection, qualified units are packaged using high-performance protective materials tailored to their specific requirements: shockproof foam inserts and reinforced cartons mitigate impact damage, moisture-proof barriers prevent humidity-related degradation, and tamper-evident seals ensure product integrity. These packaged products are then systematically stored in our climate-controlled warehouse—equipped with real-time temperature and humidity monitoring, dust-free storage zones, and barcode-enabled inventory management—to maintain optimal condition. The warehouse’s organized racking system, aligned with logistics schedules, ensures products are readily accessible, guaranteeing timely delivery in line with subsequent shipping arrangements and customer requirements.

Company Strength:

Boasting three decades of vigorous, innovation-driven growth, the company has strategically expanded its market presence to span both domestic frontiers and global arenas, evolving into a benchmark enterprise in the high-end industrial components sector. Its comprehensive product portfolio—engineered for durability, precision, and performance—has gained widespread adoption across critical, high-growth industries: construction machinery (excavators, cranes, and loaders), onshore/offshore wind power generation (gearbox components for turbines), new energy vehicles (electric drivetrain parts), high-speed rail transit (transmission systems), petrochemical processing (heavy-duty equipment components), and mining machinery (wear-resistant, high-load parts). Each product line is tailored to meet the rigorous operational demands of these sectors, reflecting the company’s commitment to technical alignment with industry needs.On the global stage, the company has forged deep-rooted, long-term cooperative relationships with world-renowned enterprises hailing from industrial powerhouses including the United States, Canada, Germany, Italy, Belgium, and Japan—with partnerships extending to key markets across Europe, North America, and Asia. These collaborations encompass joint R&D initiatives, customized product development, and seamless supply chain integration, with overseas sales now contributing to over 50% of its total annual revenue. Domestically, it maintains strategic, mutually beneficial partnerships with China’s leading high-end equipment manufacturers, including Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. These alliances involve co-engineering solutions, localized production support, and synchronized innovation, solidifying the company’s role as a trusted supplier to the nation’s advanced manufacturing ecosystem. Within its diverse product lineup, two core offerings stand out as domestic market leaders: planetary reducer forgings (critical for precision power transmission in industrial machinery) and medium-to-large hook assemblies (essential for heavy-lifting applications in construction and mining). Both products hold the top position in domestic market share, a distinction earned through continuous investment in advanced manufacturing technologies (such as precision forging and CNC machining), rigorous quality control systems, and a customer-centric approach to product optimization. This market leadership not only underscores the company’s technical prowess but also reinforces its reputation as a reliable partner for driving efficiency and innovation across key industries worldwide.