Planetary Speed Reducer Gear

1.Material:17CrNiMo6-4/18CrNiMo7-6

2.Machining accuracy:

External cylindrical grinding: ±0.001mm

Tooth accuracy: Grade 5

3.Mold opening cycle:About 30 days

4.Customization: Made-to-order services are available.

5.Advantages:

Full-process inspection

Full-process processing capability

Full-range products

6.Weight/Size: Produce according to the drawings.

7.Craft:Forging

Product Introduction:

Planetary gears are a integral element of the planetary gear mechanism in wind turbine speed-increasing gearboxes. Their manufacturing gadget is especially complex and many times consists of strategies such as steelmaking, forging, post-forging normalizing and tempering, difficult machining, carburizing and quenching, and finishing. Each manner has strict requirements for processing accuracy and first-rate to make positive the dimensional accuracy, enamel profile accuracy, and flooring exceptional of the planetary gears, thereby guaranteeing their reliable operation beneath high-speed and heavy-load conditions.

Product Advantages:

Planetary gears as a key issue of the planetary gear train, the graph and manufacturing benefits at as soon as have an impact on the transmission efficiency, reliability, and provider existence of speed-increasing gearboxes. With a couple of teeth collaboratively bearing loads, they feature immoderate residence utilization, engaging in a balance between lightweight and immoderate strength. Their profile alternate science improves meshing accuracy, making certain convenient transmission with low vibration and noise. The enamel surfaces undergo intensive shot peening remedy to form a compressive stress layer, thereby extending fatigue resistance and service life.

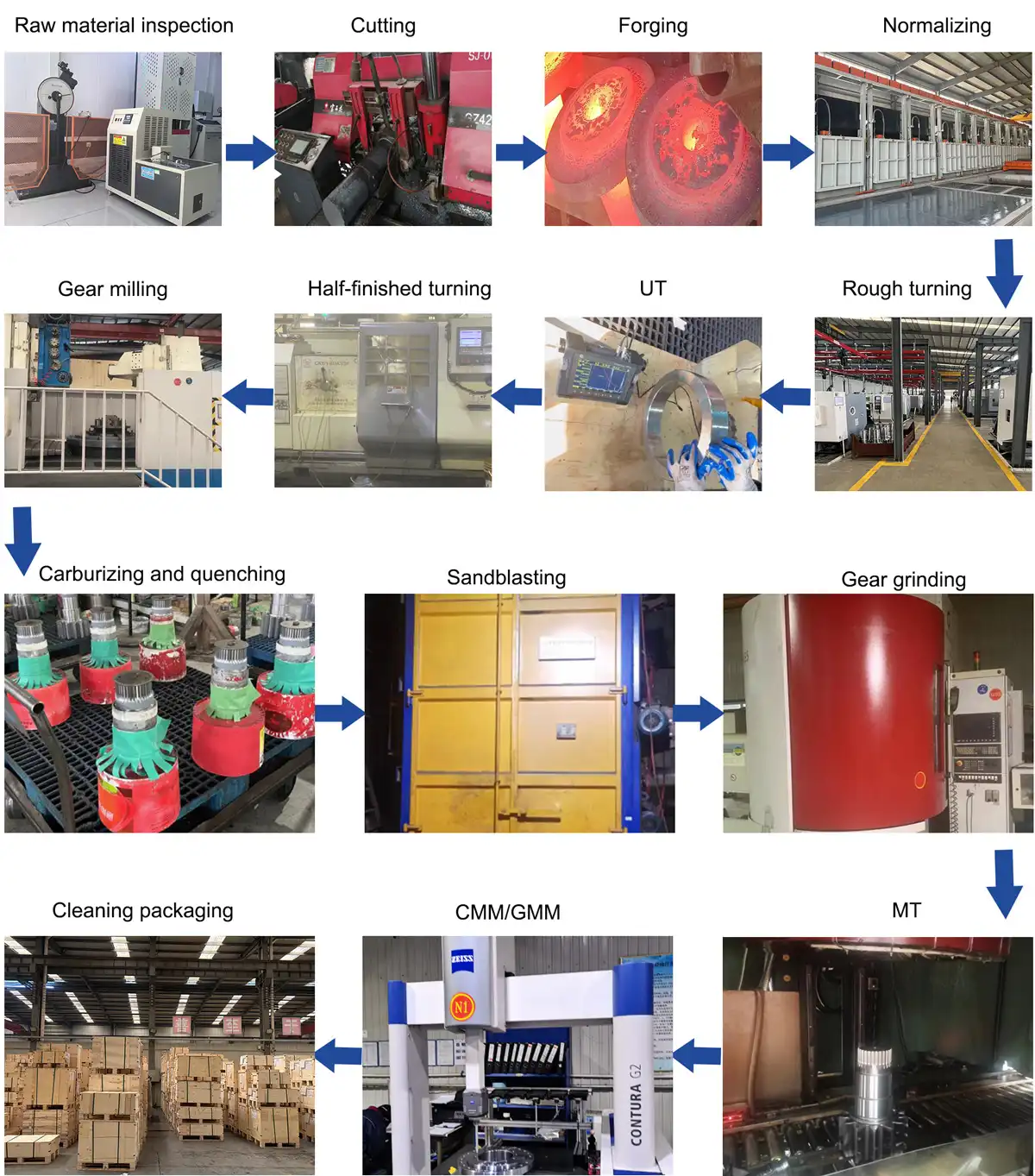

Production Process:

Raw material inspection → Cutting → Forging → Normalizing → Rough turning → UT → Half-finished turning → Gear milling → Carburizing and quenching → Sandblasting → Gear grinding → MT → CMM/GMM → Cleaning packaging

Packaging And Shipping:

Before the goods are shipped, they must go through a complete pre-treatment process. First, the goods are thoroughly cleaned to remove surface stains and impurities, ensuring their appearance is clean. Subsequently, standardized labeling is applied, clearly indicating product information, specifications, and relevant instructions. Additionally, anti-rust treatment is specifically carried out; oxidation and rusting are slowed down through the application of coatings or protective agents. Immediately after, quality inspectors conduct a detailed visual inspection to check for defects such as scratches and deformations. Finally, the goods that pass the inspection are properly packaged to ensure safety during transportation, and then stored in the warehouse temporarily, waiting for shipment arrangements. These series of links are interlocking, forming a complete quality control chain from cleaning to warehousing, laying a reliable foundation for the smooth transportation and subsequent use of the goods.

Company Strength:

The employer is fully equipped with a suite of cutting-edge inspection and testing instruments, including imported spectrometers, nitrogen-hydrogen-oxygen analyzers, Zeiss metallographic microscopes, Zeiss coordinate measuring machines (CMMs), and M2M ultrasonic phased array flaw detectors. This advanced array of equipment empowers the organization with comprehensive capabilities to conduct thorough inspections across multiple critical dimensions: from analyzing the chemical composition of raw materials and evaluating their performance metrics, to precisely measuring dimensional accuracy, assessing structural integrity, and verifying positional tolerances. Moreover, it extends to carrying out rigorous non-destructive testing, ensuring that even minute internal flaws or irregularities are detected without compromising the integrity of the materials or products. Such a robust testing infrastructure not only guarantees the reliability and quality of the materials and products at every stage but also underscores the employer’s commitment to maintaining the highest standards of precision and excellence in its operations.