Excavator forgings: The "hard core bones" for heavy-duty operations, the core components that determine the durability and efficiency of excavators!

Excavator forgings: The "hard core bones" for heavy-duty operations, the core components that determine the durability and efficiency of excavators!

In high-intensity operation scenarios such as mining and infrastructure construction, excavators have to withstand extreme tests like rock impacts, heavy-load friction, and complex terrain vibrations every day. And forgings, as the "manufacturing foundation" of the core load-bearing components of excavators, with strength, toughness, and wear resistance far exceeding those of castings, have become the key guarantee for the normal operation of excavator hydraulic systems, walking mechanisms, and working devices. Many equipment purchasers and construction teams are puzzled: Which components of excavators are forgings? Why can high-quality forgings reduce the breakdowns of excavators? How to select excavator forgings suitable for heavy-duty working conditions? This article will dissect the core value of excavator forgings from three dimensions: application scenarios, process advantages, and selection techniques.

1. Excavator forgings: The "key components" for the core system

Every time an excavator digs, rotates, or moves, it cannot do so without the stable support of forgings. These forged components, formed through high-temperature forging, are distributed in all major core systems of the excavator and are the "pillar" that withstands extreme conditions:

Working device core: bucket teeth, connecting rods, bucket rods forgings

Bucket teeth are the "digging tools" of the excavator, which need to bite into rocks and hard soil directly. They are manufactured using alloy steel forging technology, with a surface hardness of up to HRC55-60, and their wear resistance is more than twice that of ordinary castings, reducing downtime losses due to frequent replacements. Connecting rod forgings connect the boom and bucket rods, and through overall forging, internal defects are eliminated, with tensile strength exceeding 1000 MPa, capable of easily handling the alternating loads during excavation. Bucket rod forgings use variable-section controlled forging technology, with an anti-tensile strength of up to 1400 MPa level, suitable for high-intensity operation requirements.

Transmission system key: gears, transmission shafts, chain wheel forgings

The transmission system is the "power center" of the excavator. Gear and transmission shaft forgings are formed through precise forging, with fine and uniform grain structure, capable of withstanding high torque transmission. The transmission efficiency is over 15% higher than that of ordinary processed parts. Chain wheel forgings, as the "driving core" for crawler movement, undergo carburizing heat treatment, with a surface that is wear-resistant and a core that is tough, able to withstand continuous impact and friction during crawler meshing, extending the service life of the walking system.

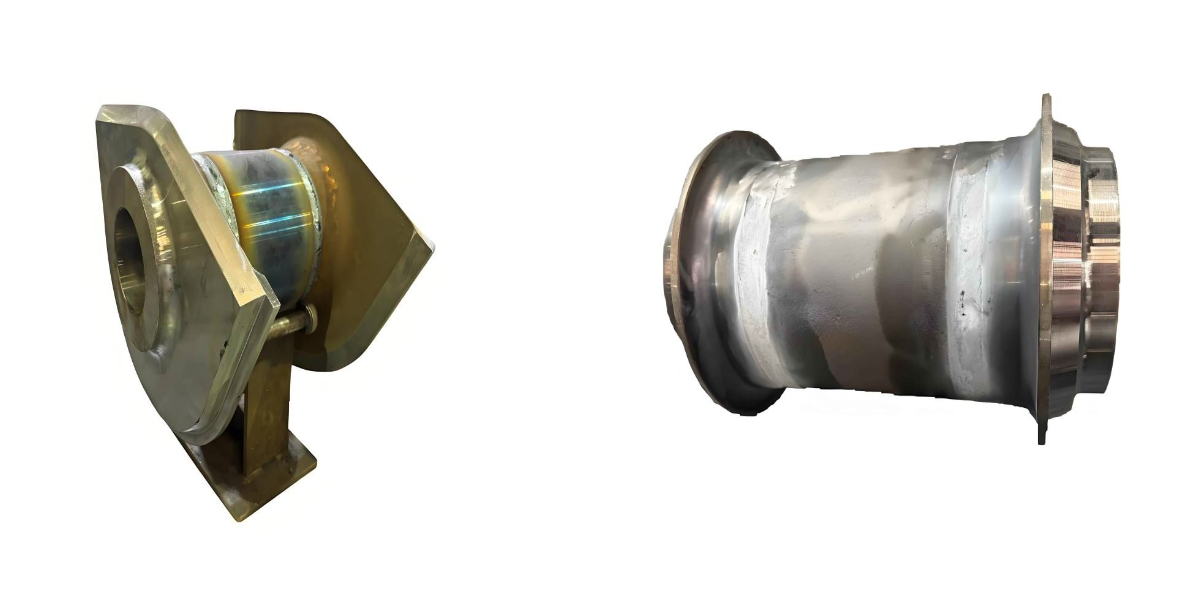

Hydraulic system core: piston rods, cylinder bodies, valve blocks forgings

The hydraulic system drives the excavator to perform precise operations. The piston rod forgings are made through solid forging + quenching treatment, not only having high compressive strength but also being able to resist corrosion from water vapor in the construction environment through surface anti-corrosion treatment, with an operational failure-free working time of over 12,000 hours. Cylinder bodies and valve blocks forgings are formed through forging to achieve integrated complex structures, with dimensional accuracy up to IT9-IT11, ensuring no leakage in the hydraulic system and improving the sensitivity of action response.

Walking system key: crawler plates, support wheel shafts, pin shaft forgings

Crawler plates forgings undergo closed forging + surface hardening treatment, with a 2-fold improvement in sand particle erosion resistance, suitable for complex terrains such as mines and infrastructure. Support wheel shaft forgings support the overall weight of the excavator, through electro-hydraulic hammer forging to ensure dense structure, impact toughness ≥ 80 J/cm², able to avoid bending deformation under heavy loads. Pin shaft forgings, as the connection hubs of various components, are made through high-precision forging technology, with size tolerances controlled within ±0.1-0.3 mm, ensuring precise assembly and connection reliability.

2. Forging process: The "core advantages" of excavator forgings for heavy-duty operations

The harshness of the operating environment of excavators determines that core components must adopt forging technology. Forgings, with their unique manufacturing advantages, have become the standard choice for high-end excavator models:

Dual strength and toughness, resisting extreme loads

The forging process, through high-temperature and high-pressure forging of metal billets, breaks down large grains and arranges them densely, completely eliminating common defects such as pores and sand holes in castings. The tensile strength and impact resistance of excavator forgings have been enhanced by 30% - 50% compared to castings, effectively preventing component fractures and deformations during heavy-load operations. This has reduced the downtime rate of excavators from 3% to 0.5%.

High wear resistance and fatigue resistance, lower maintenance costs

Given the high-frequency operation characteristics of excavators, forgings are made from high-strength alloy steels such as 42CrMo and 35CrMo, combined with heat treatment processes like carburizing and nitriding. The fatigue limit (10⁷ cycles) has increased by 30% - 50%. For example, the service life of high-quality bucket teeth forgings can be three times that of ordinary castings, significantly reducing maintenance frequency and replacement costs. The annual after-sales cost of a single excavator can be reduced by over 25,000 yuan.

Precise dimensions, stronger adaptability

Precision die forging technology enables "near-net-shape" production of excavator forgings, with a machining allowance of only 1-2mm and a surface roughness of Ra ≤ 3.2μm. This ensures perfect compatibility with other components, avoiding excessive gaps that cause vibration and increased wear. For special working conditions, customized forging can be adjusted for structural parameters, such as customizing stainless steel forgings resistant to salt fog corrosion for coastal construction excavators, with an anti-corrosion ability of 1000 hours without rust.

Stable batch production, higher cost-effectiveness

Die forging is suitable for mass production, with one set of molds capable of producing tens of thousands of products. The single-piece production cycle is only 3-5 minutes, which is 5-8 times more efficient than free forging. At the same time, the material utilization rate is 70%-85%, much higher than the 50%-60% of casting. This can reduce the cost per unit by 20%-30% while ensuring quality, meeting the requirements of large-scale procurement of engineering equipment.

III. Guide for Selecting Excavator Forgings: 3 Key Points to Avoid Purchase Mistakes

For engineering enterprises and equipment maintenance companies, choosing the right forgings is crucial for ensuring construction efficiency and reducing maintenance costs. When purchasing, attention should be paid to the following three points:

Verify the process and test reports

Prioritize products made through die forging or electro-hydraulic hammer forging. Die forgings have stable performance, and electro-hydraulic hammer forging can ensure a forging ratio of ≥ 3:1, effectively eliminating internal defects. Suppliers are required to provide complete test reports, including material analysis sheets, non-destructive testing reports (ultrasonic testing, magnetic particle testing), to ensure that the forgings have no cracks, inclusions, etc. The qualification rate of non-destructive testing must be above 99.5%.

Select materials and processing methods based on working conditions

Select based on the working scenarios: heavy-load scenarios in mines, prioritize alloy steel forgings with carburizing treatment, with a surface hardness of HRC55 or above; in coastal high-humidity environments, choose stainless steel substrates with passivation treatment; for high-frequency operation equipment, select tempered forgings with uniform hardness between HB280-320.

Pay attention to the manufacturer's qualifications and application cases

Prioritize suppliers with a complete industrial chain (smelting - forging - heat treatment - finishing processing), ensuring material consistency and process stability. At the same time, pay attention to the manufacturer's industry cases, and preferentially choose suppliers with cooperation with well-known excavator brands or large engineering enterprises, whose products have been verified in actual working conditions, ensuring more reliable adaptability.

IV. Industry Trends: Intelligent Upgrade Drives Iteration of Excavator Forgings

As excavators evolve towards larger sizes and intelligence, the output of die forgings in China is expected to reach over 20 million tons by 2025, with a continuous increase in the demand for high-end forgings for excavators. In the future, excavator forgings will upgrade in three directions: first, product precisionization, optimizing processes through digital simulation technology, with dimensional accuracy reaching micrometer levels; second, production intelligence, using automated forging equipment and real-time monitoring systems to ensure consistency in product performance; third, greenification, optimizing processes to reduce energy consumption and emissions, achieving "green forging". Meanwhile, domestic forging technology has made rapid progress, breaking the foreign monopoly. Some of the products have reached the international advanced level in terms of performance, and have become cost-effective choices.

Summary

Forgings are the "strong bones" of excavators. From bucket teeth to transmission shafts, from hydraulic piston rods to track plates, the quality of every high-quality forging directly affects construction efficiency, equipment lifespan, and operating costs. In the current era of increasing heavy-load operation demands, choosing high-quality excavator forgings that are suitable for specific working conditions has become a key to reducing costs and increasing efficiency for engineering enterprises.

If you need to learn more about customized solutions for excavator forgings, adaptation cases for different working conditions, or obtain a technical parameter comparison table for excavator forgings, please feel free to contact us at any time! We will provide you with high-quality forging products that comply with industry standards and professional technical support.

- Previous : Coal mining machinery forgings: The "hardcore confidence" for efficient coal mining, the core components all rely on them to withstand extreme working conditions!

- Next : New energy vehicle forgings: The core code of lightweight and high performance, determining range, safety and durability!