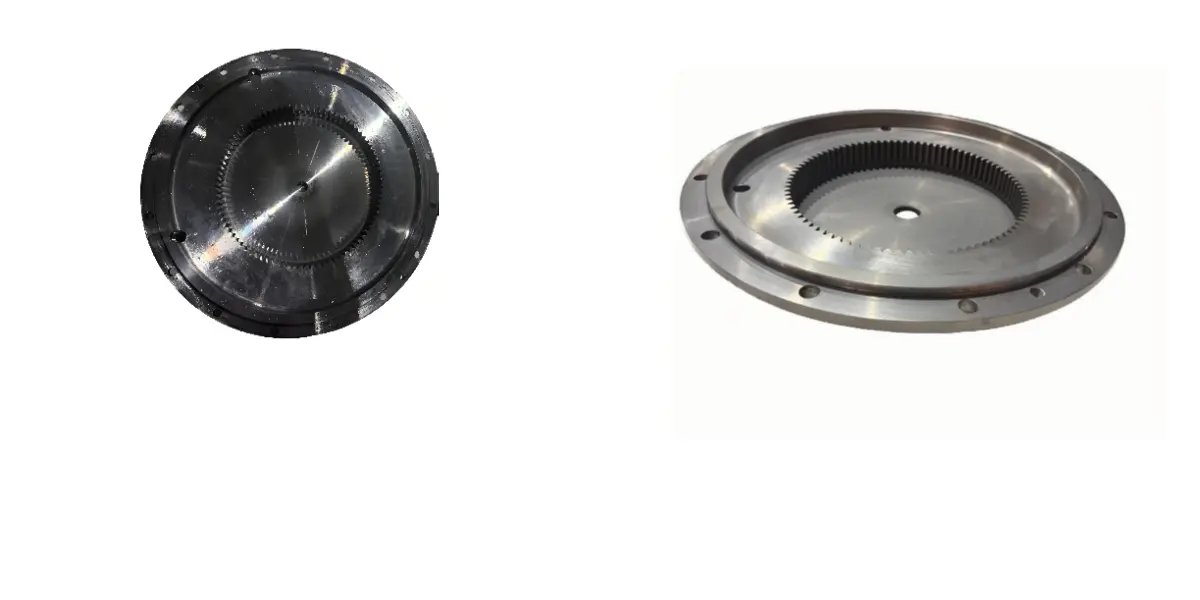

Industrial Gear End Cover

1.Material:42CrMo/45#

2.Machining accuracy:±0.01mm

3.Mold opening cycle:About 45 days

4.Customization: We design and manufacture tailor-made products to your exact technical requirements.

5.Advantages:

Our strict process inspection ensures every product meets defect-free standards.

Streamlined one-stop processing delivers efficiency and cost savings.

From standard to custom, our wide product range solves all your needs.

6.Weight:Material usage and end-product weight will be derived from the Client’s provided drawings.

7.Craft:Forging

Product Introduction:

End covers are key factors in industrial tools used to seal, protect, or tightly closed openings. They belong to the classification of disc cowl components. Their core elements embody sealing, protection, support, and connectioAlthough a small component, the stop cowl acts as the "safeguard" of industrial equipment. Its a range of sketch continuously revolves spherical three core principles: reliability, environmental adaptability, and surroundings pleasant production.Looking ahead, with the improvement of new electricity sources and clever manufacturing, stop covers will proceed to spoil new ground in the directions of lightweight, intelligent, and eco-friendly design. They will emerge as an critical "industrial guardian" for high-end equipment.

Product Advantages:

End covers, as necessary factors in industrial equipment, expose advantages in sealing and protection, structural support, material adaptability, and financial benefits.Efficient Sealing and Protection | Dustproof and Waterproof:By sealing pipelines, bearing housings, or tools interfaces, they efficiently block the ingress of dust, moisture, and oil contaminants, making positive a convenient environment for internal components. This makes them gorgeous for features such as vehicle engines and wind electrical energy equipment.Structural Support and Stability:Forged steel provide up covers can stand up to axial hundreds of up to 20 kN. Their rib-reinforced format enhances bending and torsional resistance, making them best for use in ore grinding mills and heavy machinery.

Production Process:

Raw material inspection→ Cutting→ Forging → Normalizing → Rough turning → UT → Quenched and tempered → Shot peening → MT → Finished turning → Drilling and Tapping → Shaping → CMM/GMM → Cleaning packaging

Cleaning and Packaging

Our group will:

Clean, label, and take a show up to be at rust-proofing to all merchandise until now than than shipment;

Perform a meticulous exhibit up inspection;

Finally pack the merchandise and preserve them in our warehouse, making exquisite readiness for dispatch.

Company Strength:

Over the preceding 30 years of full of life development, the company has aggressively extended into every and each and every and each and every and each domestic and world markets. Its merchandise are appreciably used in fields such as placing up machinery, wind electrical electrical energy generation, new electrical electrical electricity vehicles, rail transit, petrochemicals, and mining machinery. The organization has set up in-depth cooperation with world-renowned businesses in the United States, Canada, Germany, Italy, Belgium, Japan, and super countries, with far-off locations capital customer profits accounting for increased than 50%. It has in addition regular strategic partnerships with domestic predominant high-end tools producers such as Zoomlion, XCMG, Sany, Lingsheng, CRRC, Nanjing Gear, and Zhuzhou Gear. Among its products, the market share of planetary reducer core forgings and medium-to-large lifting hook assemblies ranks first in the domestic market.